Nano fuel catalytic synthesis particles

A technology for synthesizing particles and nanometers, applied in the direction of physical/chemical process catalysts, heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of shortening the service life of working equipment, additive market reputation and Poor acceptance, fuel equipment damage and other problems, to achieve the effect of solving technical problems of maintenance and energy saving and emission reduction, solving technical problems of energy saving and emission reduction, and high fuel combustion efficiency

Inactive Publication Date: 2017-03-22

广东绿水青山生态科技有限公司

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing fuel additives are mainly single-function detergents, antiknock agents, pour point depressants, etc., and the market is mainly facing consumers with detergents, which mainly clean carbon deposits. Even if there are other auxiliary functions, the effect is very good. Limited, some even caused damage to fuel oil equipment, and technical problems have not been resolved, resulting in poor market reputation and acceptance of the additive industry

[0004] At the same time, energy saving, environmental protection, and pollution reduction have been paid attention to by many countries. Therefore, saving oil resources and solving the pollution problems of exhaust emissions are people's requirements for modern fuels; The active ingredient of fuel oil, but the salt is an ionic compound, which can separate metal cations and acid radical ions in the solution. Although the ionic bond generated by the electrostatic attraction between ions is relatively strong, the ionic bond produced by it when the fuel burns The high temperature is enough to have the energy to open chemical bonds, so that it can separate metal ions and acid radical ions, and acid radical ions will corrode metal parts, and when chemical bonds are opened, molecules always absorb energy. Therefore, using salts as catalysts will have a certain amount of energy. Wear and tear and shorten the service life of working equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

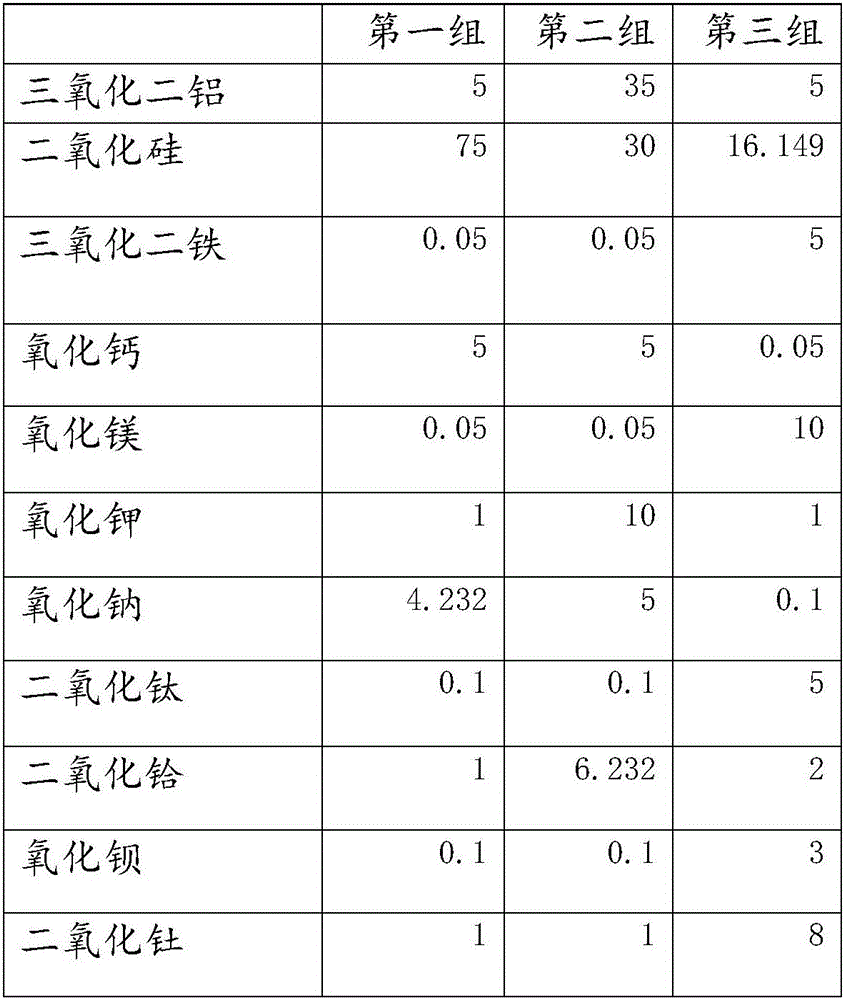

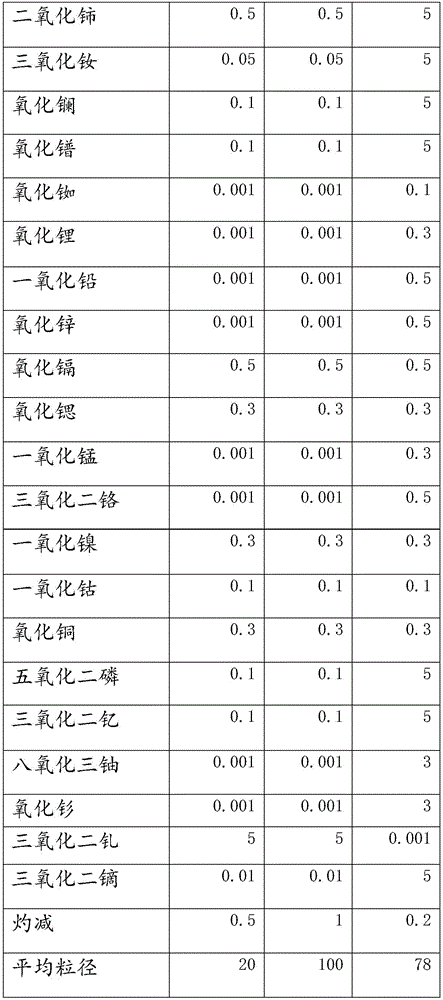

[0174] Nano-fuel catalytic synthesis particles, including, the mass percentage is, see Table 1:

[0175] Table 1: The percentage content (%) of each component in each group of nano-fuel catalytic synthesis particles, the mass percentage (%) of each group of ignition loss, and the average particle diameter (nm) of each group of nanoparticles

[0176]

[0177]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides nano fuel catalytic synthesis particles. The nano fuel catalytic synthesis particles are prepared from nano metallic oxides, nano rare earth element oxides and nano transition metal oxides. Compared with the prior art, the nano fuel catalytic synthesis particles solve the energy conservation and emission reduction problems fundamentally according to the work principle of fuel equipment. Based on the principle that the fuel equipment produces thermal energy through fuel combustion and converts the thermal energy into kinetic energy through an engine system, the maintenance, repairing and performance improvement of an engine as well as catalysis of fuel for improvement of combustion efficiency are researched. With the adoption of the nano fuel catalytic synthesis particles, the fuel combustion efficiency is high, the conversion rate of the engine is high, and the technical problems about maintenance, energy conservation and emission reduction of the fuel equipment are solved.

Description

technical field [0001] The invention relates to the technical field of fuel catalysts, and more specifically relates to a nanometer fuel catalytic synthesis particle. Background technique [0002] With the increase of the number of domestic locomotives in recent years, the consumption of fuel oil such as gasoline and diesel is increasing day by day, and a large amount of imported oil is needed to meet the demand of the domestic market. The demand for the development of fuel-saving additives and alternative oil products is becoming more and more urgent. Existing gasoline (or diesel) has few branched chain alkanes and low octane number (cetane number), which is prone to knocking phenomenon in which fuel and air are mixed and spontaneously ignites, resulting in insufficient fuel combustion, producing carbon monoxide, nitrogen oxide and unburned gas. Harmful substances such as hydrocarbons and black smoke affect the ecological environment and human health; solid substances such ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/889

CPCB01J23/002B01J23/8892B01J2523/00B01J2523/31B01J2523/41B01J2523/23B01J2523/842B01J2523/22B01J2523/12B01J2523/13B01J2523/47B01J2523/49B01J2523/25B01J2523/395B01J2523/3725B01J2523/3712B01J2523/3706B01J2523/3718B01J2523/14B01J2523/11B01J2523/27B01J2523/44B01J2523/72B01J2523/845B01J2523/847B01J2523/67B01J2523/28B01J2523/24B01J2523/36B01J2523/17B01J2523/3737B01J2523/375B01J2523/397B01J2523/3762B01J2523/15

Inventor 周伟彬

Owner 广东绿水青山生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com