Device and method for recycling phosphorus and magnesium from phosphorus ore magnesium removal liquid

A technology for removing magnesium and phosphate rock, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low purity of magnesium ammonium phosphate, reduced magnesium removal rate, and many impurities, and achieves short reaction time and reduced Consume, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

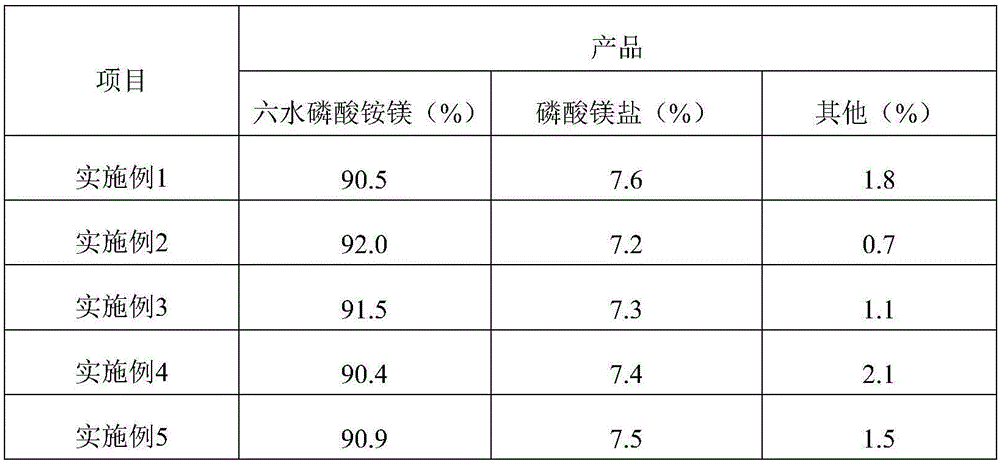

Embodiment 1

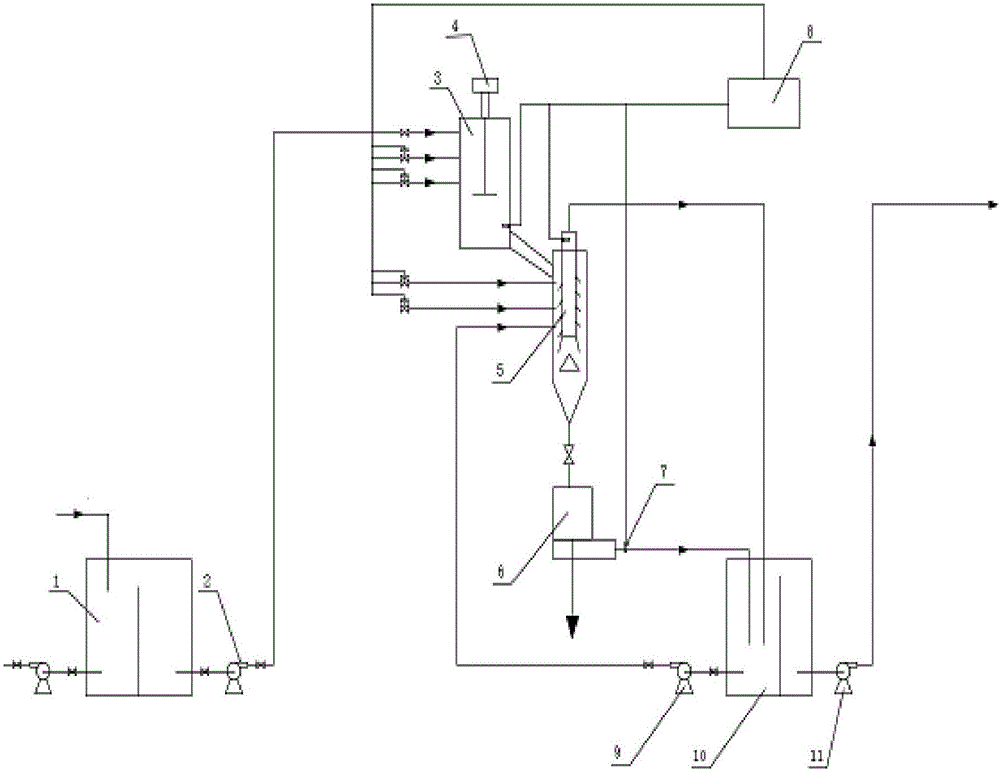

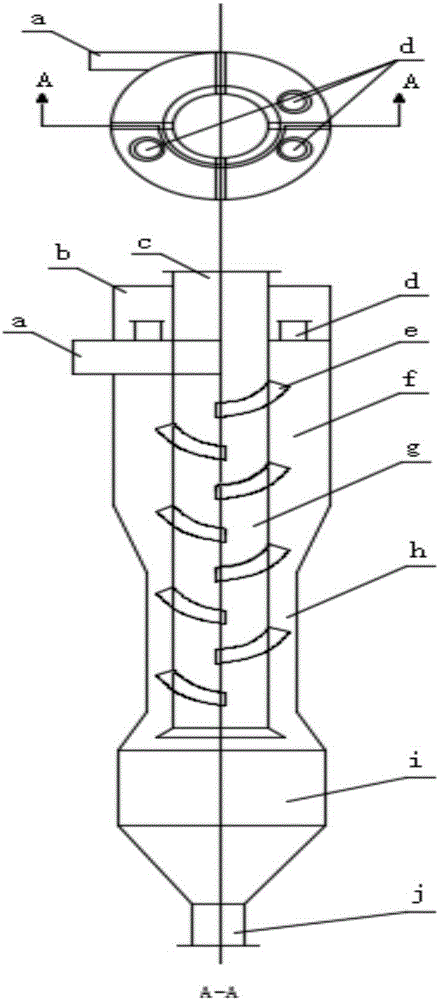

[0030] Such as figure 1 Shown: A device for recovering phosphorus and magnesium from phosphate rock demagnesium solution, including demagnesium solution clarification tank, reaction liquid clarification tank, high-level reactor, low-level reactor, pH detection head, pH console, centrifuge, magnesium removal The liquid clarification tank is connected to the high-level reactor through the upper liquid pump and the connecting pipe of the magnesium removal liquid. The high-level reactor is built into the high-level reactor for stirring. The other side of the liquid clarification tank is connected to the purification liquid pump, and the pH detection heads are respectively set at the outlet of the high-level reactor and the low-level reactor and connected to the pH console.

[0031] The pH detection head and the pH console form a pH monitoring system, which controls the flow rate of the precipitant according to the feedback relationship between the detected real-time pH value and t...

Embodiment 2

[0041] A device for recovering phosphorus and magnesium from a phosphate rock demagnesizing solution is carried out according to the content described in Example 1.

[0042] A method for recovering phosphorus and magnesium from a phosphate ore demagnesium solution. In step 2), the pH value of the high-level reactor is controlled to be 5.5-6.0, the pH value of the low-level reactor is controlled to be 7.0-7.5, and the pH value of the high-level reactor is controlled. The reaction time is 10min, and the reaction time in the low-level reactor is 10min; in step 3), the clarification operation is after stirring for 2h, then standing for 10h, and the remaining conditions and operations are carried out according to the content of Example 1.

Embodiment 3

[0044] A device for recovering phosphorus and magnesium from a phosphate rock demagnesizing solution is carried out according to the content described in Example 1.

[0045] A method for recovering phosphorus and magnesium from a phosphate ore demagnesium solution. In step 2), the pH value of the high-level reactor is controlled to be 5.5-6.0, the pH value of the low-level reactor is controlled to be 7.0-7.5, and the pH value of the high-level reactor is controlled. The reaction time is 5min, and the reaction time in the low-level reactor is 7min; in step 3), the clarification operation is after stirring for 0h, then standing for 10h, and the remaining conditions and operations are carried out according to the content of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com