Co-production method of monophenol compound and activated carbon by lignin catalytic pyrolysis

A single phenolic compound, catalytic pyrolysis technology, applied in chemical instruments and methods, preparation of organic compounds, carbon compounds, etc., can solve the problem of insufficient conversion, harsh and complex research process, and the lack of by-products of thermal conversion of lignin. Improve utilization and other issues to achieve the effect of increasing productivity, simple process, improving utilization rate and utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

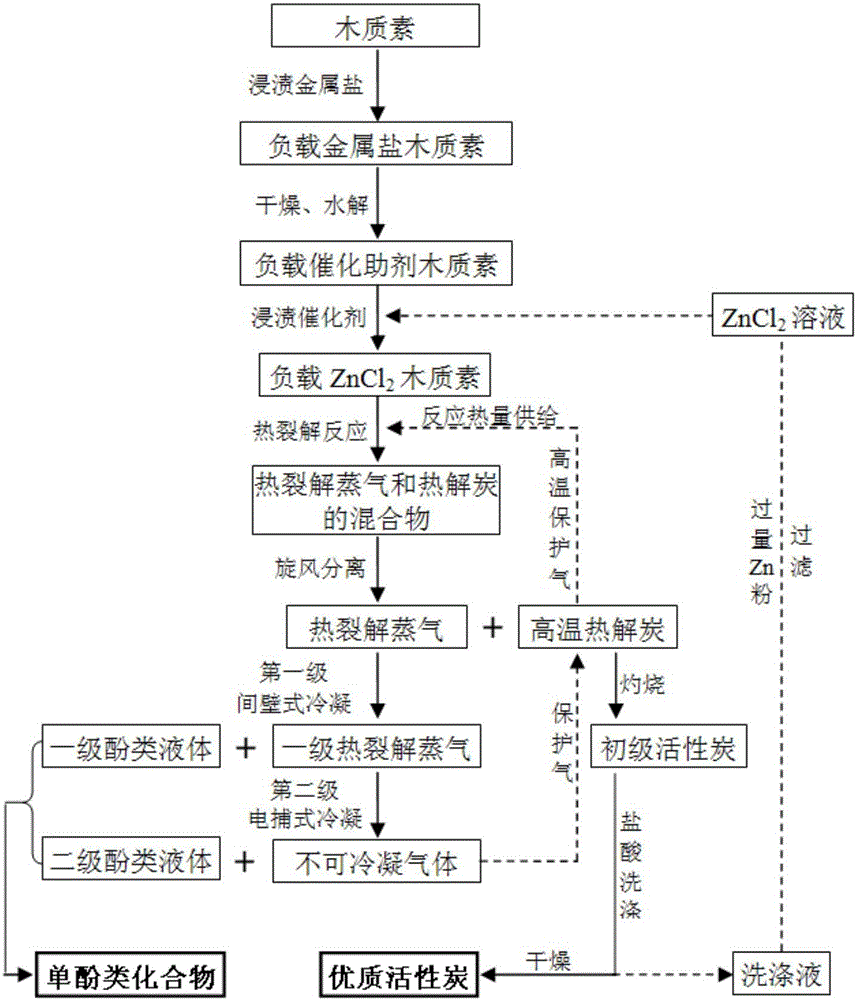

Method used

Image

Examples

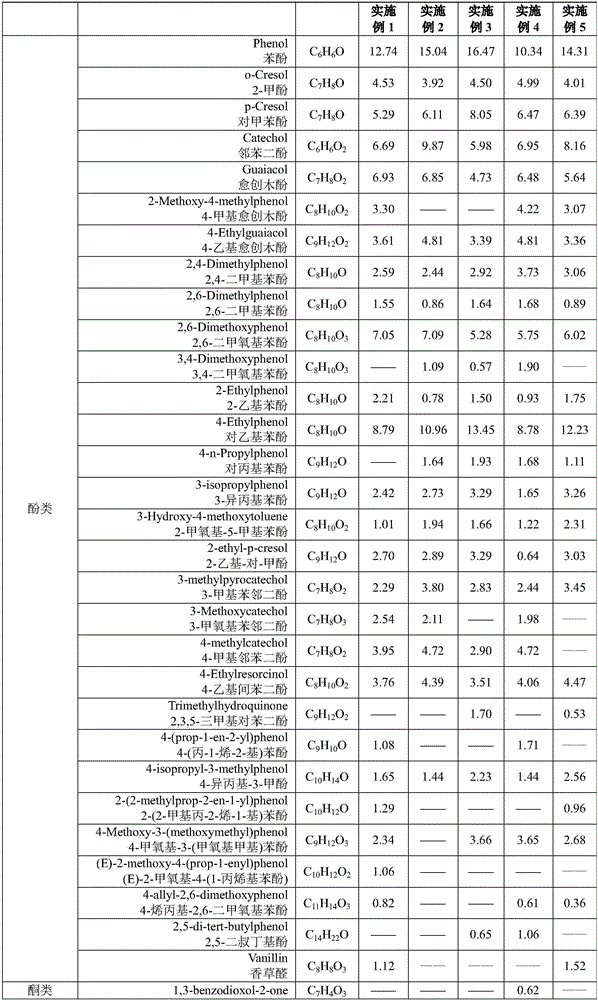

Embodiment 1

[0043] Taking the lignosulfonate raw material as an example to introduce the implementation process of the present invention is as follows:

[0044] Soak lignosulfonate in 0.1mol / L CuCl 2 5 hours in solution, lignosulfonate and anhydrous CuCl 2 The mass ratio is 1:0.01, and then dried at 120°C for 8 hours to obtain the supported CuCl 2 Lignosulfonate; supported CuCl 2 Lignosulfonate soaked in 1mol / L ZnCl 2 10 hours in solution, loaded with CuCl 2 The mass ratio of lignosulfonate to anhydrous zinc chloride is 1:0.5, and then vacuum-dried at 60°C and hydrogen chloride protective gas for 5 hours, and after drying, thermal cracking reaction is carried out at 450°C and 0.5 second reaction time, Generate high-temperature pyrolytic carbon and pyrolysis steam; pyrolysis steam is condensed in two stages, the first stage is condensed at a condensation temperature of 5°C to obtain a first-stage phenolic liquid, and the second stage is electro-captured at a voltage of 10kV Condensate...

Embodiment 2

[0047] Taking the mixture of kraft lignin and hydrolyzed lignin as a raw material to introduce the implementation process of the present invention as follows:

[0048] Soak kraft lignin in 0.3mol / L FeCl 3 7 hours in solution, kraft lignin with anhydrous FeCl 3 The mass ratio was 1:0.05, and then dried at 125°C for 5 hours to obtain the loaded FeCl 3 Kraft lignin; loaded with FeCl 3 Kraft lignin soaked in 3mol / L ZnCl 2 20 hours in solution, loaded with FeCl 3 The mass ratio of kraft lignin to anhydrous zinc chloride is 1:1, and then vacuum-dried at 65°C and hydrogen chloride protective gas for 6 hours, and after drying, thermal cracking reaction is carried out at 500°C with a reaction time of 3 seconds to generate High-temperature pyrolytic carbon and pyrolysis steam; pyrolysis steam is condensed in two stages, the first stage is condensed at a condensation temperature of 2°C to obtain a phenolic liquid, and the second stage is condensed by electric capture at a voltage of ...

Embodiment 3

[0051] Taking the alkali lignin raw material as an example to introduce the implementation process of the present invention is as follows:

[0052] Soak the alkali lignin in NiCl with a concentration of 0.5mol / L 2 10 hours in solution, alkali lignin and anhydrous NiCl 2 The mass ratio is 1:0.1, and then dried at 130°C for 5 hours to obtain the loaded NiCl 2 Alkali lignin; loaded NiCl 2 Alkali lignin soaked in ZnCl with a concentration of 5mol / L 2 40 hours in solution, loaded with NiCl 2 The mass ratio of alkali lignin to anhydrous zinc chloride is 1:1.5, and then vacuum-dried at 70°C and hydrogen chloride protective gas for 5 hours. After drying, thermal cracking reaction is carried out at 650°C and 2.5 seconds reaction time to generate Pyrolytic carbon and pyrolysis steam; pyrolysis steam is condensed in two stages, the first stage is condensed at a condensation temperature of 0°C to obtain a phenolic liquid, and the second stage is condensed by electric capture at a volt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com