Hollow microsphere molecular sieve and preparation method thereof

A technology of molecular sieves and microspheres, applied in the direction of molecular sieve catalysts, molecular sieve characteristic polycrystalline silicon, chemical instruments and methods, etc., can solve the problems of complex steps, time-consuming and labor-consuming, etc., and achieve the effect of easy separation and simple and fast synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of preparation method of hollow microsphere molecular sieve, comprises the following steps:

[0041] adjusting the pH value of the mixture comprising silicon source, templating agent, EDTA chelating agent and water to 8-11 to obtain a sol;

[0042] Carrying out hydrothermal crystallization to the sol to obtain molecular sieve powder;

[0043] The molecular sieve raw powder is calcined to obtain a hollow microsphere molecular sieve.

[0044] In the present invention, the silicon source, template agent, EDTA chelating agent and water are preferably mixed first to obtain a mixed solution; then the pH value of the mixed solution is adjusted to 8-11 to obtain a sol. In the present invention, the molar ratio of the silicon source, template agent, EDTA chelating agent and water is preferably 1:0.05~0.2:0.06~0.12:21~41, more preferably 1:0.08~0.18:0.08~0.11 :25~35, most preferably 1:0.1~0.15:0.09~0.1:28~32.

[0045] In the present invention, the...

Embodiment 1

[0062] According to the molar ratio Si: n-butylamine: EDTA-Na 2 : The ratio of water=1:0.15:0.08:31, water, n-butylamine and EDTA-Na 2 Mix, and finally add silica sol (JN-40, 40.5wt%of SiO 2 , Qingdao Haiyang Chem. Co.).

[0063] The pH of the synthesis system was maintained at 8.5 with 5 mol / L NaOH solution, and stirred at a rate of 500 r / min for 0.5 h to form a uniform sol.

[0064] The above-mentioned sol was transferred into a synthesis kettle lined with polytetrafluoroethylene, and rotated and dynamically crystallized at a speed of 20 r / min for 38 hours in a homogeneous reactor at 170°C.

[0065] The crystallized product was fully washed, centrifuged and dried at 105°C for 12 hours to obtain the molecular sieve powder.

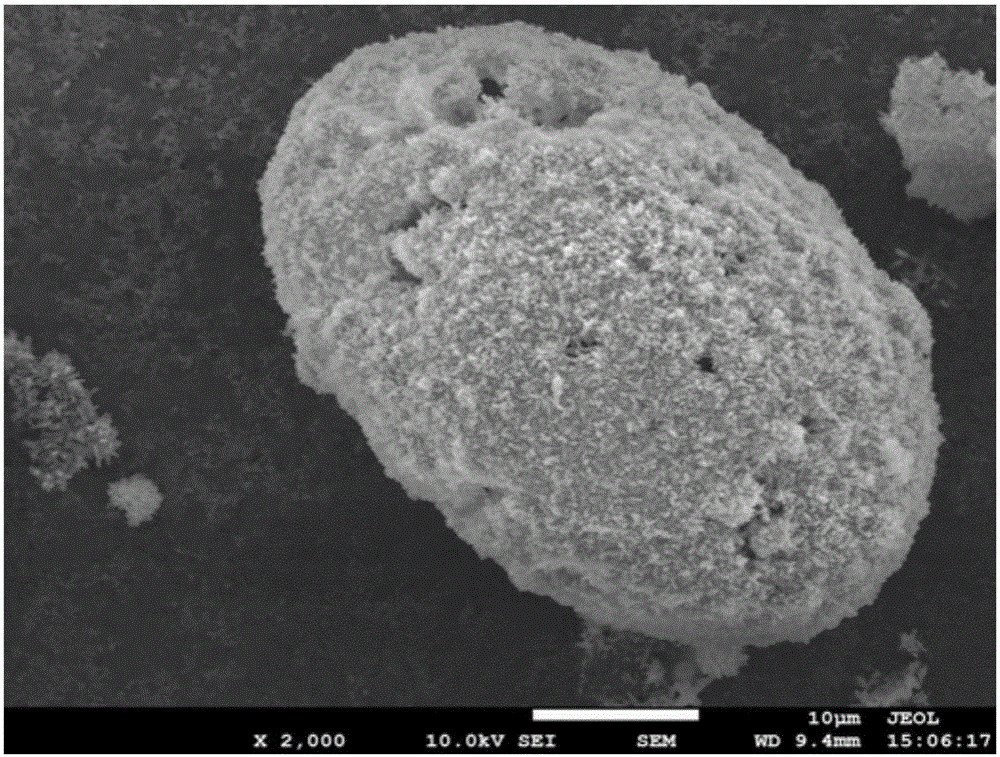

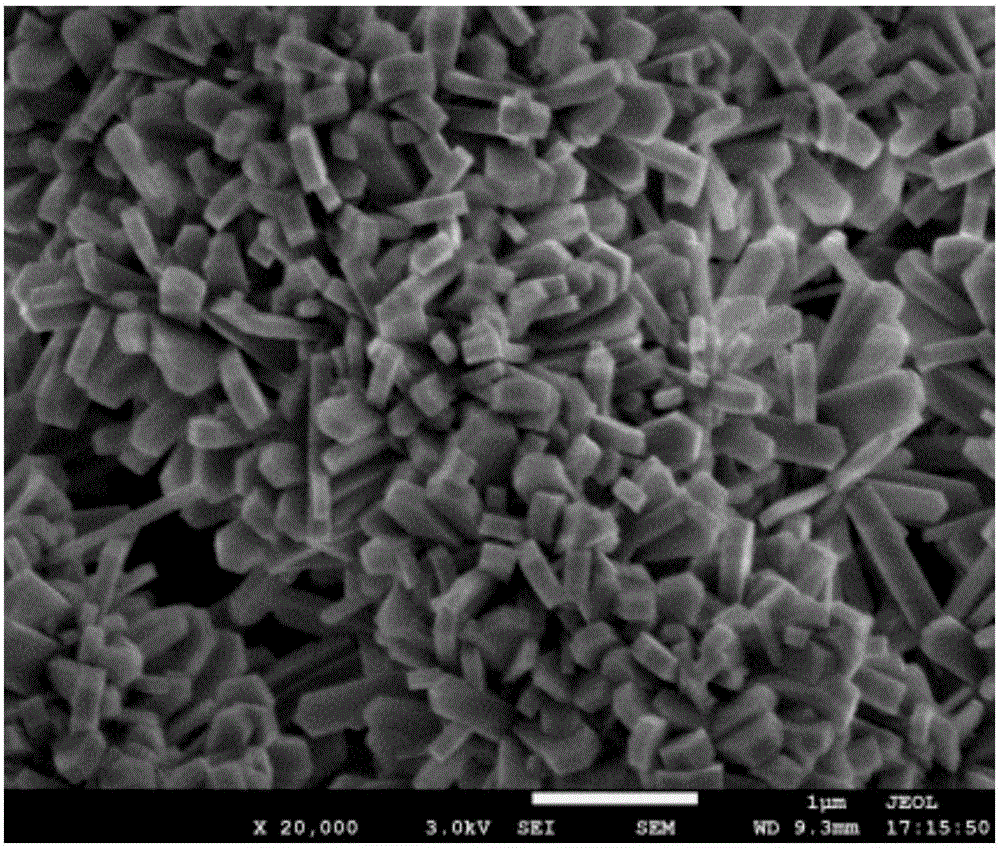

[0066] The original powder was calcined at 450° C. for 24 hours in the air to obtain the hollow microsphere molecular sieve silicalite-1.

[0067] According to XRD analysis, the hollow microsphere molecular sieve prepared in this example has an MFI st...

Embodiment 2

[0070] According to the ratio of molar ratio Si:Ti:n-butylamine:EDTA:water=1:0.02:0.15:0.08:31, EDTA and n-butylamine are added into water successively, after stirring until clarification, tetrabutyl titanate is added, and finally to the above Ethyl orthosilicate was added dropwise to the sol.

[0071] Use 5 mol / L NaOH solution to maintain the pH of the synthesis system = 11, and stir at 500 r / min for 0.5 h to form a uniform sol.

[0072] The above sol was transferred into a synthesis kettle with a polytetrafluoroethylene liner, and in a homogeneous reactor at 170°C, it was rotated and dynamically crystallized at a speed of 20r / min for 150h.

[0073] The crystallized product was fully washed, centrifuged and dried at 105°C for 12 hours to obtain the molecular sieve powder.

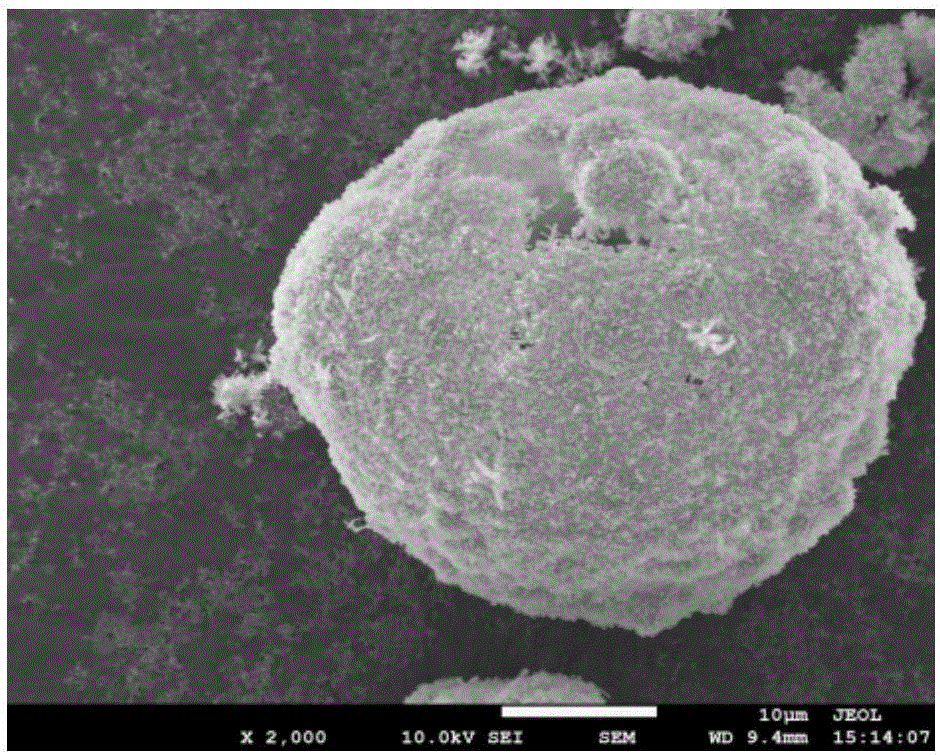

[0074] The original powder was calcined at 450°C for 24 hours in air to obtain hollow microsphere titanium silicon molecular sieve TS-1.

[0075] According to XRD analysis, the hollow microsphere molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com