Pillared layered mordenite, and preparation method thereof

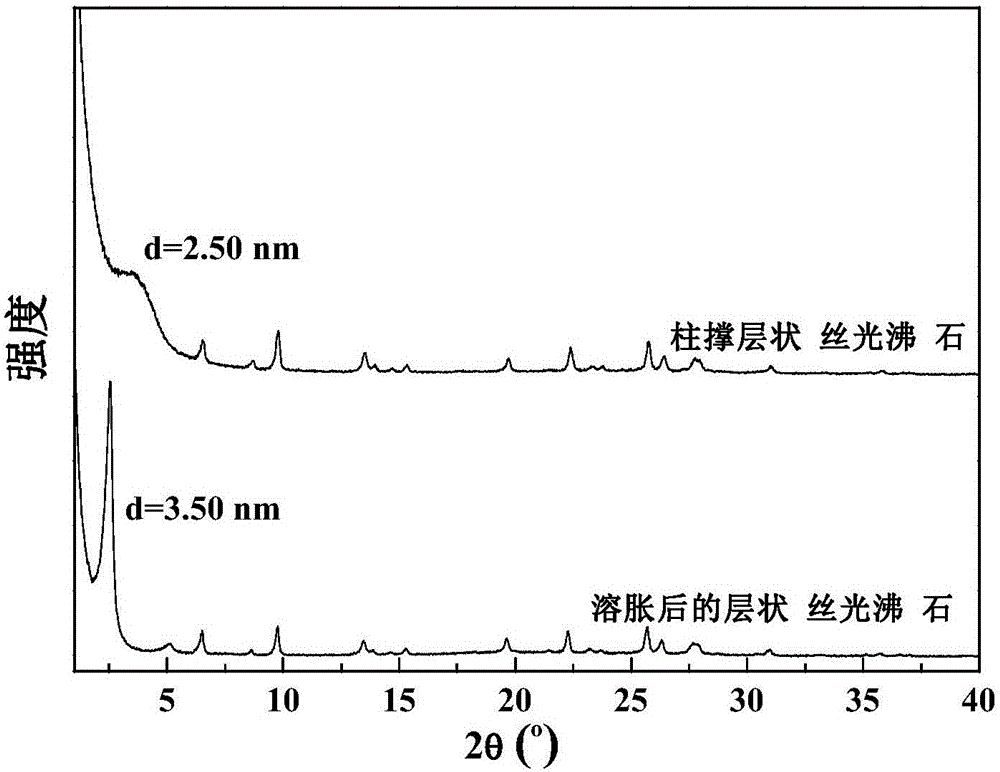

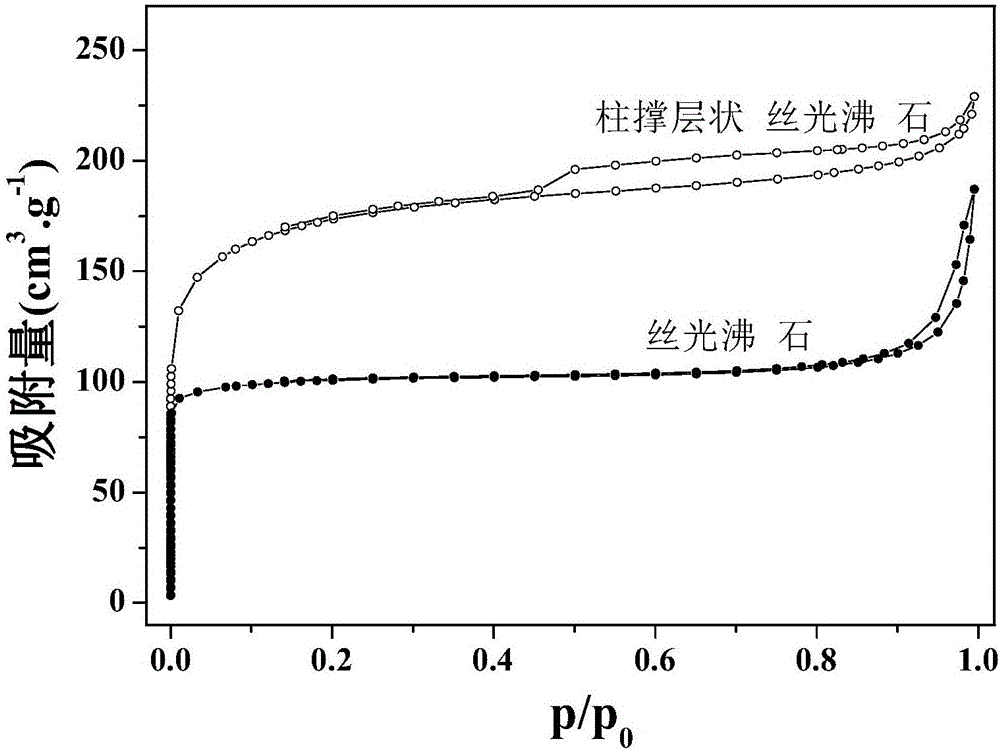

A mordenite and layered technology is applied to the preparation of swellable layered mordenite and its swelling and pillaring, and the field of pillared layered mordenite and its preparation can solve the problem of low crystallinity of mordenite and difficulty in controlling mesopores structure and distribution to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

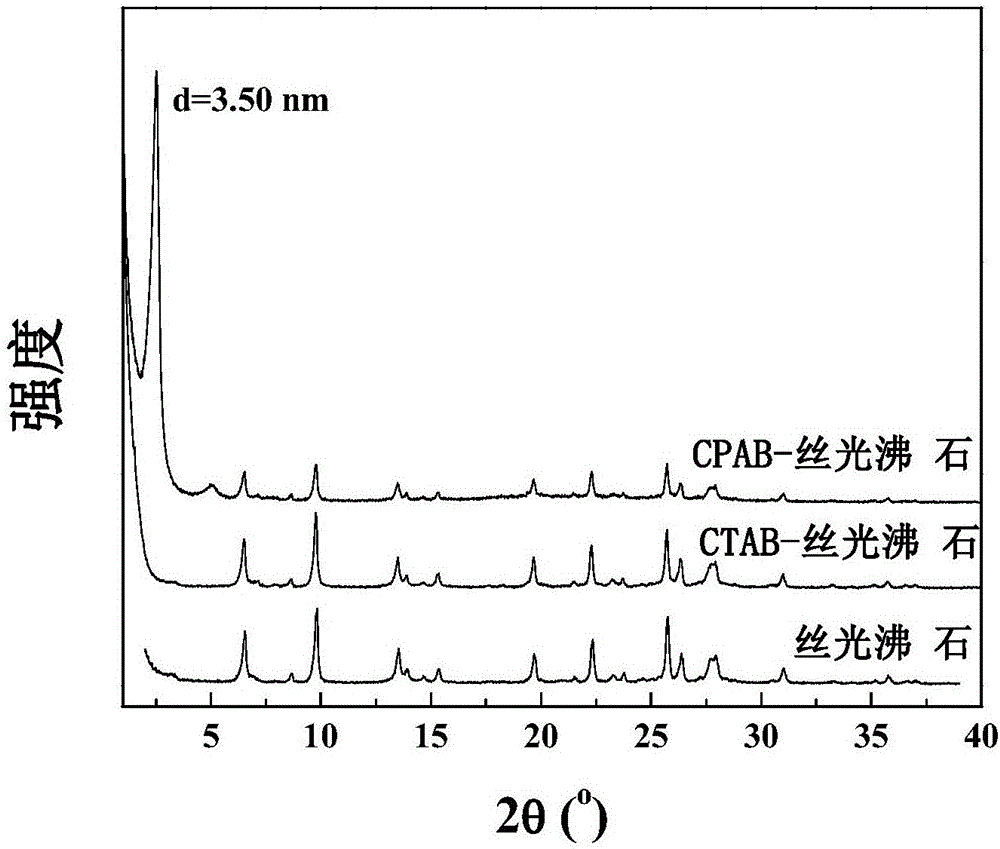

[0025] 1. Preparation of swellable layered mordenite

[0026] According to molar ratio SiO 2 / Al 2 o 3 =30, OH / SiO 2 =0.3, Na / SiO 2 =0.3, HMI / SiO 2 =0.5,H 2 O / SiO 2 =40, weigh 0.28g of sodium metaaluminate, 0.42g of sodium hydroxide, 5.05g of silica sol, 1.69g of HMI, 24.10mL of deionized water, and dissolve sodium hydroxide in 8.04mL of deionized water to prepare hydrogen Sodium oxide aqueous solution, dissolving sodium metaaluminate in 16.06mL deionized water to prepare sodium metaaluminate aqueous solution; add silica sol, HMI to the prepared sodium metaaluminate aqueous solution in sequence, and then add the prepared Aqueous sodium hydroxide solution was stirred at room temperature for 30 minutes, then the resulting mixture was transferred to a hydrothermal reaction kettle containing a polytetrafluoroethylene liner, and the hydrothermal reaction kettle was put into a homogeneous reactor, and the homogeneous reactor was set The rotation speed was 60 rpm, and the rea...

Embodiment 2

[0032] 1. Preparation of swellable layered mordenite

[0033] According to SiO 2 / Al 2 o 3 The molar ratio is 50, OH / SiO 2 The molar ratio is 0.3, Na / SiO 2 The molar ratio is 0.3, HMI / SiO 2 The molar ratio is 0.6, H 2 O / SiO 2 The molar ratio is 40, weigh 0.16g of sodium metaaluminate, 0.41g of sodium hydroxide, 4.98g of silica sol, 1.99g of HMI, and 23.89mL of deionized water, and dissolve sodium hydroxide in 7.99mL of deionized water Prepare sodium hydroxide aqueous solution, dissolve sodium metaaluminate in 15.9mL deionized water to prepare sodium metaaluminate aqueous solution; add silica sol, HMI to the prepared sodium metaaluminate aqueous solution in sequence, and then add dropwise The prepared aqueous sodium hydroxide solution was stirred at room temperature for 30 minutes, then the resulting mixture was transferred to a hydrothermal reaction kettle containing a polytetrafluoroethylene liner, and the hydrothermal reaction kettle was put into a homogeneous reactor...

Embodiment 3

[0039] 1. Preparation of swellable layered mordenite

[0040] According to SiO 2 / Al 2 o 3 The molar ratio is 100, OH / SiO 2 The molar ratio is 0.4, Na / SiO 2 The molar ratio is 0.4, HMI / SiO 2 The molar ratio is 0.5, H 2 O / SiO 2 The molar ratio is 30, weigh 0.1g of sodium metaaluminate, 0.7g of sodium hydroxide, 6.32g of silica sol, 2.11g of HMI, and 22.72mL of deionized water, and dissolve sodium hydroxide in 7.57mL of deionized water Prepare sodium hydroxide aqueous solution, dissolve sodium metaaluminate in 15.15mL deionized water to prepare sodium metaaluminate aqueous solution; add silica sol, HMI to the prepared sodium metaaluminate aqueous solution in sequence, and then add dropwise The prepared aqueous sodium hydroxide solution was stirred at room temperature for 30 minutes, then the resulting mixture was transferred to a hydrothermal reaction kettle containing a polytetrafluoroethylene liner, and the hydrothermal reaction kettle was put into a homogeneous reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com