Refining system and refining process of brine for production of salt from sea water

A refining system and brine technology, applied in the direction of alkali metal chlorides, etc., can solve the problems of inability to remove colloids, low removal efficiency, and low sand filtration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

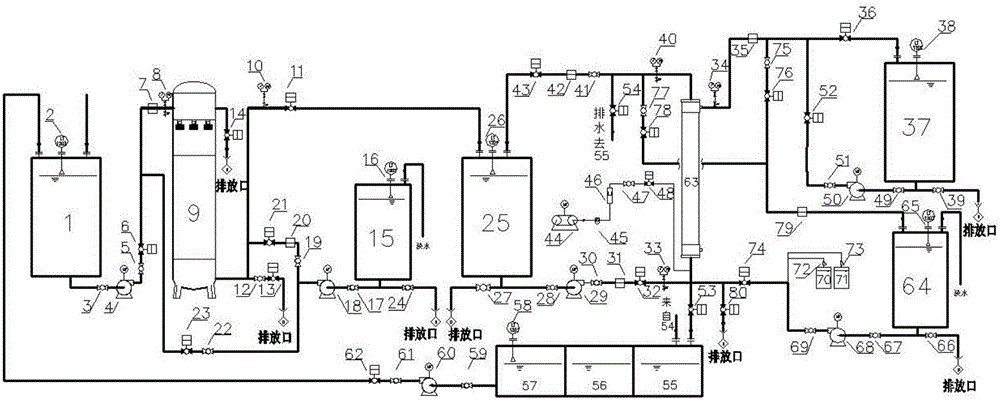

Method used

Image

Examples

Embodiment

[0048] From March to May 2016, 100 tons / day demonstration research was carried out in Hangu.

[0049] Demonstration study treatment effect:

[0050] ①Turbidity removal effect

[0051] Table 1

[0052]

[0053]

[0054] Table 1 is the turbidity table of the influent and product water of the system. The monitoring data shows that the turbidity of the influent water is between 5.67 and 145NTU, and the turbidity of the product water is kept below 0.2NTU. After two months of operation tests, the ability of the ultrafiltration membrane to intercept various colloidal pollutants has not changed and remains in a very stable and efficient state.

[0055] ②SS removal effect

[0056] Table 2

[0057]

[0058] Table 2 is the SS sampling test table of the system influent and product water; the data show that the SS of the system product water at this stage is lower than 1.0mg / L, the SS removal rate is higher than 99.9%, and the ability of the ultrafiltration membrane to retain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com