Preparation method of alpha-Fe2O3/TiO2 nano-composite gas sensing material

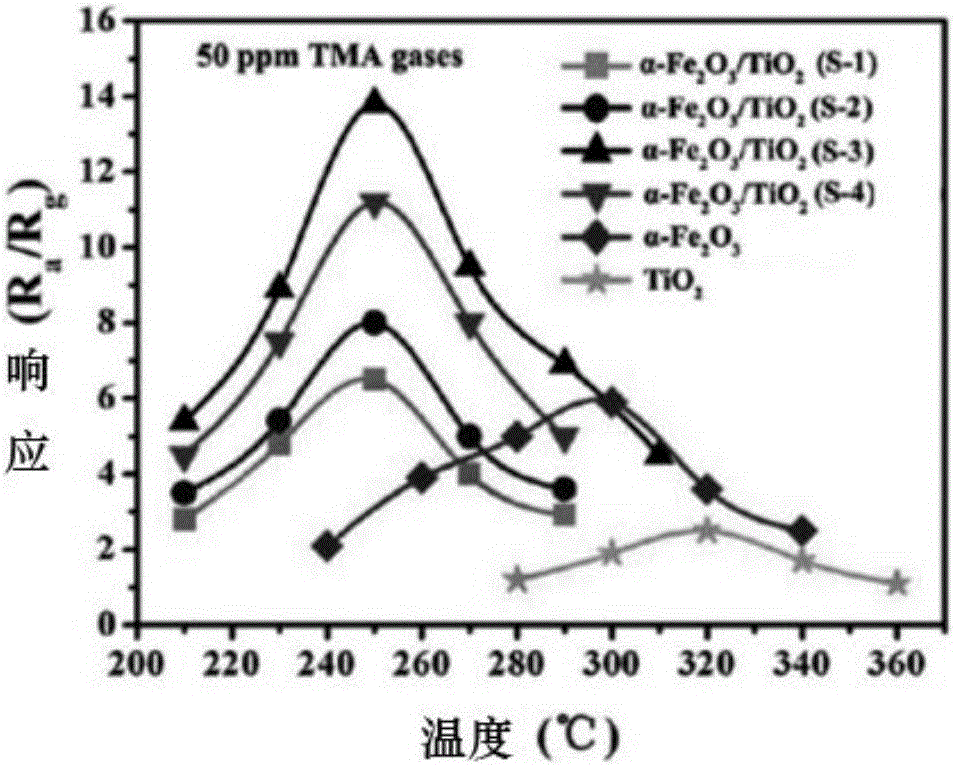

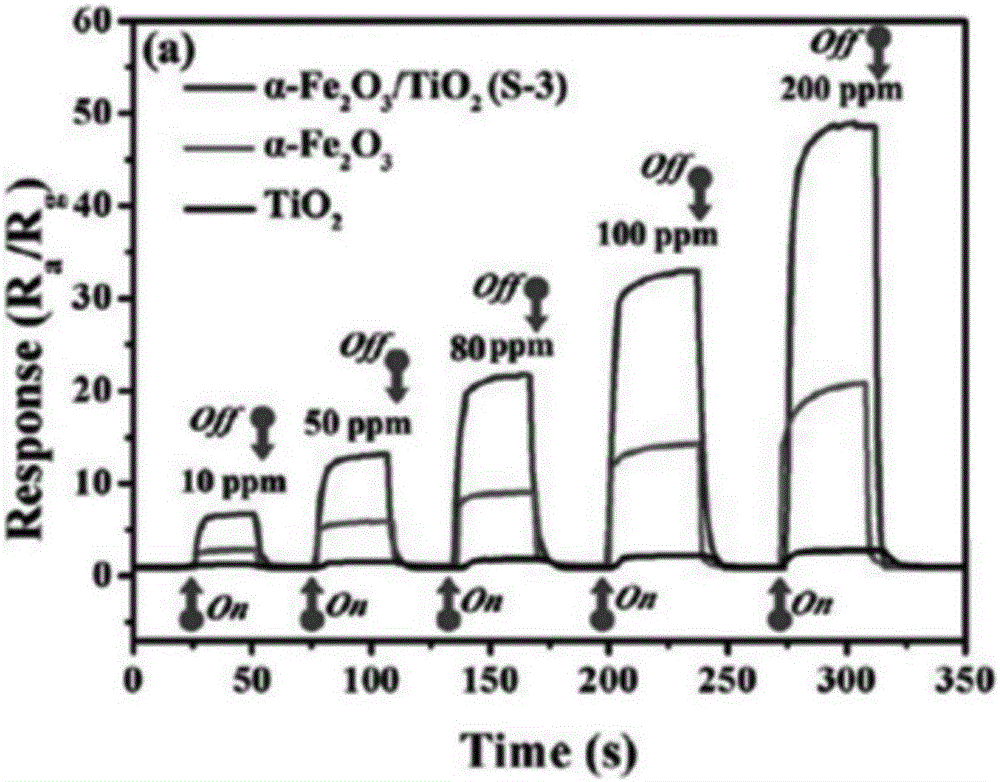

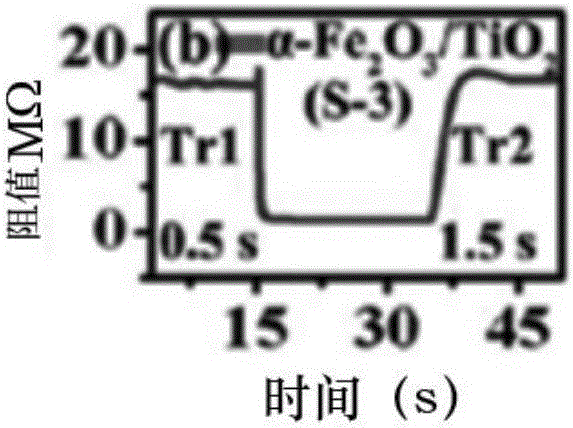

A gas-sensing sensing material and nano-composite technology, which is applied in the field of preparation of α-Fe2O3/TiO2 nano-composite gas-sensing sensing materials, to achieve the effect of strong theory, strong sensitivity and good gas-sensing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of α-Fe that the embodiment of the present invention provides 2 o 3 / TiO 2 A method for preparing a nanocomposite gas-sensing sensing material, comprising the steps of:

[0025] Step 1. TiO 2 Preparation of nanofibers: Using tetrabutyl titanate, glacial acetic acid, absolute ethanol and polyvinylpyrrolidone PVP as raw materials, TiO was prepared by electrospinning technology. 2 / PVP composite nanofiber film, obtained TiO after calcination 2 Nanofibers;

[0026] Step 2. α-Fe 2 o 3 / TiO 2 Preparation of nanocomposite gas-sensing sensing materials: first FeCl 3·6H 2 O was dispersed into the mixed solution of deionized water and ammonia water, stirred for 10-20min, then the obtained mixed solution was transferred to a hydrothermal kettle, and the TiO prepared above was added 2 For nanofiber materials, heat the hydrothermal kettle to 95°C, react for 4h, then cool the hydrothermal kettle to room temperature, centrifuge the precipitate in the reactor with etha...

Embodiment 1

[0034] Example 1: α-Fe 2 o 3 / TiO 2 Preparation of Nanocomposite Gas Sensing Materials

[0035] First prepare the required TiO 2 nanofibers, as follows:

[0036] Mix 2g of tetrabutyl titanate with 2g of glacial acetic acid and 7.5g of ethanol, then add 0.5g of PVP to the resulting mixed solution, and stir in a constant temperature hydrothermal kettle at 98°C for 2 hours to obtain a uniform spinning solution. silk solution, cooled to room temperature, and then prepared TiO by electrospinning 2 / PVP composite nanofiber film, the prepared film was calcined at 500°C for 2h to obtain the product TiO 2 nanofiber, spare;

[0037] Preparation of TiO by Electrospinning Technology 2 / PVP composite nanofiber film, the main equipment used is a sputtering electrospinning device and a hanger-type uniform distributor; the specific operations are as follows:

[0038] 1) Pour the configured uniform spinning solution into the hydrothermal kettle, and control the liquid level of the spin...

Embodiment 2

[0045] Example 2: α-Fe 2 o 3 / TiO 2 Preparation of Nanocomposite Gas Sensing Materials

[0046] Prepare TiO according to the method of Example 1 2 nanofibers, then 0.338gFeCl 3 ·6H 2 O was dispersed into a mixed solution of 20mL deionized water and 0.05mL ammonia water, stirred for 15min, the mixed solution was transferred to a hydrothermal kettle, and then 0.01gTiO 2 The nanofiber material was put into a hydrothermal kettle, and the hydrothermal kettle was heated to 95° C. for 4 hours. Finally, the hydrothermal kettle was cooled to room temperature, and the precipitate in the reaction kettle was centrifuged several times with a mixed solution of deionized water and ethanol, and dried at 60°C for 24h, and then the material was calcined at 500°C for 2h to obtain the final product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com