Preparation method for quickly separating plant proanthocyanidin dimer and trimer

A proanthocyanidin, dimer technology, applied in the direction of organic chemistry and the like, can solve the problems of complex components of black wattle bark proanthocyanidins, no separation and purification method, complicated process, etc., and achieves high commercial value and short time consumption. , the effect of high purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

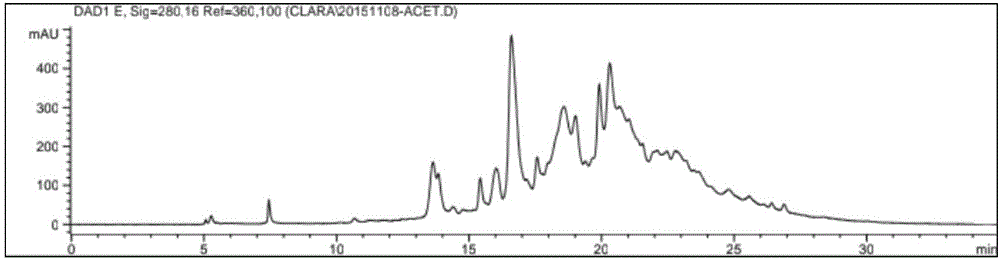

[0028] Add 10g of crushed and sieved black wattle bark raw material to 100mL of 60% ethanol according to the ratio of solid to liquid 1:10, and extract with ultrasonic wave at 50°C for 30min, and obtain the extract after filtration. The extract was concentrated by rotary evaporation, and the extract was dissolved in 200 mL of water. Add 100mL petroleum ether to the aqueous solution and extract (three times) to obtain the aqueous layer. The aqueous layer was extracted with 600 mL of ethyl acetate (three times) to obtain an ethyl acetate layer. The ethyl acetate layer is spin-dried and freeze-dried to obtain the black wattle bark ethyl acetate extract, and the liquid chromatography analysis results of its components are shown in figure 1 . Depend on figure 1 It can be seen that the components of the black wattle bark extract are complex after being extracted with ethyl acetate, and the overlapping peaks in the liquid phase diagram indicate that there are isomers of proanthocy...

Embodiment 2

[0034] Add 10g of crushed and sieved grape seed raw material to 100mL of 60% ethanol according to the ratio of solid to liquid 1:10, and extract with ultrasonic wave at 50°C for 30min, and obtain the extract after filtration. The extract was concentrated by rotary evaporation, and the extract was dissolved in 200 mL of water, and the aqueous solution was extracted with 100 mL of petroleum ether (three times) to obtain an aqueous layer. The aqueous layer was extracted with 600 mL of ethyl acetate (three times) to obtain an ethyl acetate layer. The ethyl acetate layer was spin-dried and freeze-dried to obtain the grape seed ethyl acetate extract, and the liquid chromatography analysis results of its components were shown in Figure 6 . Depend on Figure 6 It can be seen that the crude grape seed extract is extracted with ethyl acetate to obtain grape seed oligomers, which have complex components and need further separation and purification.

[0035] Dissolve 2 g of grape seed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com