Polyurethane resin used for high-density nubuck and preparation method thereof

A polyurethane resin, high-density technology, used in textiles and papermaking, etc., can solve the problem of no hydrolysis resistance and high peel strength, polyurethane nubuck resin color development and cashmere feeling are not satisfactory, and limit the development of high-end products. and other problems, to achieve the effect of good color development, fast and uniform solidification speed, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

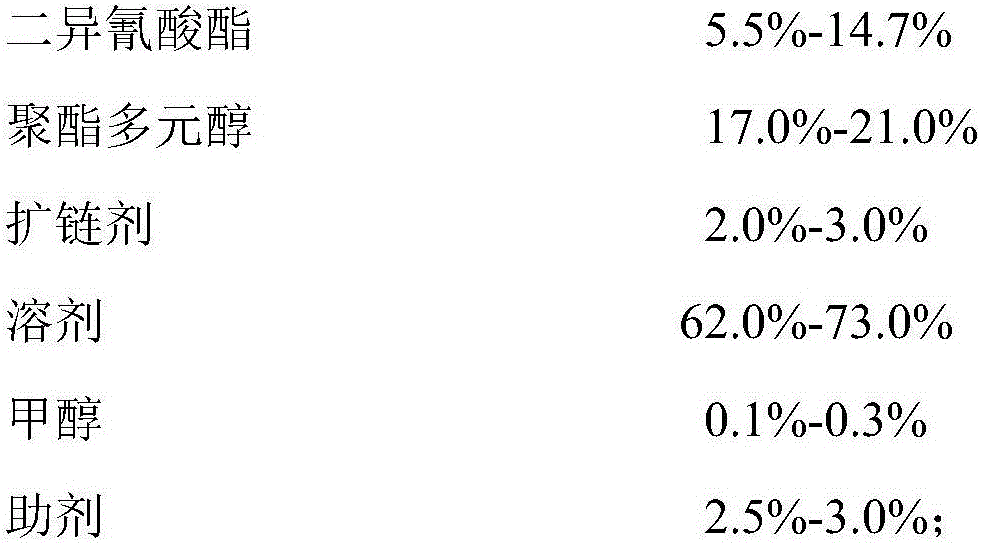

Image

Examples

Embodiment 1

[0032]

[0033] (1) 54.0kg polyadipate-1,6-hexanediol ester diol, 54.0kg polyphthalate propylene glycol ester diol, 64.8kg polycarbonate diol, 7.2kg double-ended hydroxyl polyol Add ether-modified silicone oil, 133.3kg N,N-dimethylformamide and 20.0kg 4,4-diphenylmethane diisocyanate into the reactor for prepolymerization, react at 70°C for 3.0 hours, and measure the viscosity of the reaction liquid to reach 40Pa· s / 70°C, the prepolymerization reaction is over;

[0034] The molar ratio of isocyanate group and hydroxyl group in the reaction liquid is 1:1, and the solid content is 60%.

[0035] (2) Add 23.0kg ethylene glycol and the remaining N,N-dimethylformamide, add the remaining 4,4-diphenylmethane diisocyanate after reacting for 0.5h to carry out the chain growth reaction, and measure the viscosity of the reaction solution to reach 280Pa. s / 25°C, add 1.0kg of methanol for capping, add 5.0kg of polyoxypropylene-oxyethylene diol and 20.0kg of polytetrahydrofuran, stir for...

Embodiment 2

[0037]

[0038]

[0039] (1) 64.0kg polyadipate-1,6-hexanediol ester diol, 40.0kg polyphthalate propylene glycol ester diol, 49.6kg polycarbonate diol, 6.4kg double-ended hydroxyl polyol Add ether-modified silicone oil, 94.4kg N,N-dimethylformamide and 15.3kg 4,4-diphenylmethane diisocyanate into the reactor for prepolymerization, react at 80°C for 2.0 hours, and measure the viscosity of the reaction liquid to reach 30Pa· s / 70°C, the prepolymerization reaction is over;

[0040] The molar ratio of isocyanate group and hydroxyl group in the reaction liquid is 1:1, and the solid content is 65%.

[0041] (2) Add 22.0kg of 1,4-butanediol and the remaining N,N-dimethylformamide, add the remaining 4,4-diphenylmethane diisocyanate after reacting for 1.0h to carry out the chain extension reaction, and measure the viscosity of the reaction solution When it reached 240Pa·s / 25°C, 1.5kg of methanol was added for capping, 7.1kg of polyoxypropylene triol and 16.9kg of polyoxypropylene...

Embodiment 3

[0043]

[0044] (1) 116.0kg polyadipate-1,6-hexanediol ester diol, 40.0kg polyphthalate propylene glycol ester diol, 40.0kg polycarbonate diol, 4.0kg double-ended hydroxyl polyol Add ether-modified silicone oil, 93.1kg N,N-dimethylformamide and 17.2kg 4,4-diphenylmethane diisocyanate into the reactor for prepolymerization, react at 80°C for 2.0 hours, and measure the viscosity of the reaction liquid to reach 20Pa· s / 70°C, the prepolymerization reaction is over;

[0045] The molar ratio of isocyanate group and hydroxyl group in the reaction liquid is 1.09:1, and the solid content is 70%.

[0046] (2) Add 25.0kg of 1,4-butanediol and the remaining N,N-dimethylformamide, add the remaining 4,4-diphenylmethane diisocyanate after reacting for 1.0h for chain extension reaction, and measure the viscosity of the reaction solution When the temperature reached 200 Pa·s / 25°C, 1.8 kg of methanol was added for capping, 19.4 kg of polyoxypropylene triol and 8.6 kg of polyoxypropylene tet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com