Cellulose graft modification method by using supercritical carbon dioxide as solvent

A technology of graft modification and carbon dioxide, applied in the field of polymer chemistry, to achieve the effect of simple operation, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Microcrystalline cellulose adopts the method for dissolving at low temperature to prepare a clear and transparent cellulose solution with a mass fraction of 4%;

[0055] (2) Add 2ml of the cellulose solution into a 12-hole bacterial culture plate, and let it stand for 36 hours at a gel temperature of 30° C. to prepare a cellulose gel;

[0056] (3) Repeatedly soaking the obtained cellulose gel with deionized water until the aqueous solution is neutral to obtain regenerated cellulose hydrogel;

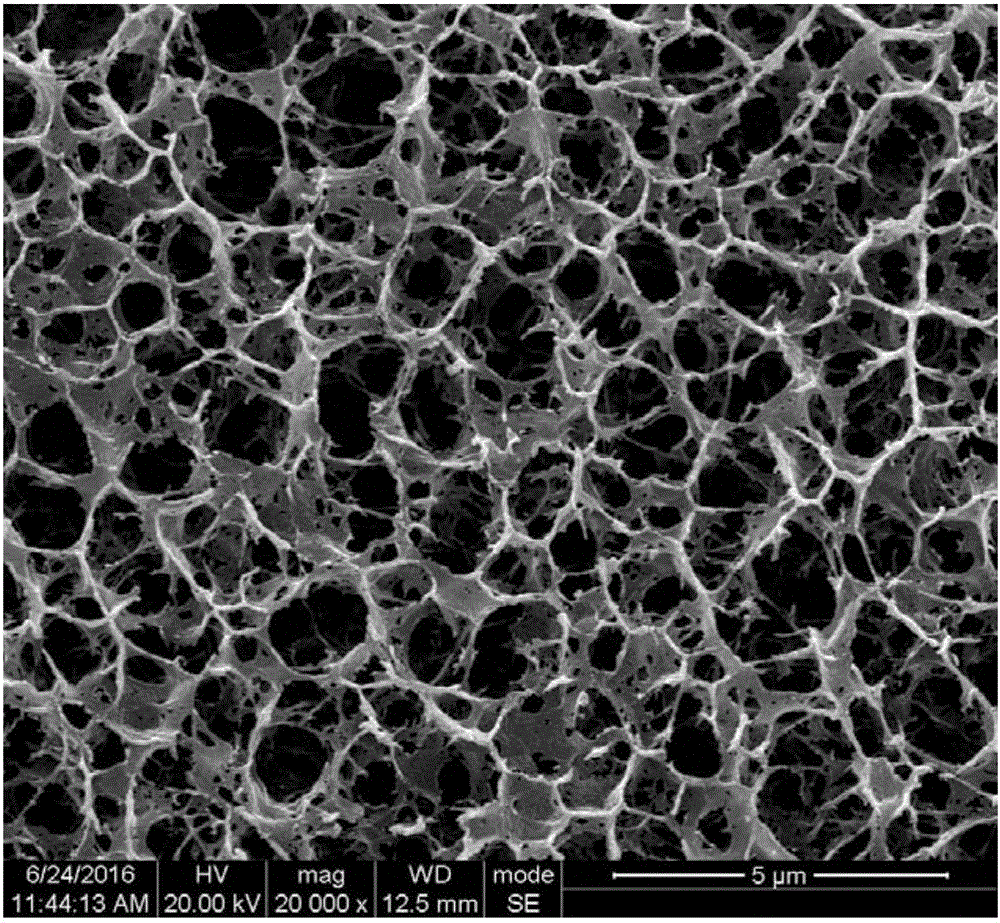

[0057] (4) Repeatedly soak the regenerated cellulose hydrogel with 5% glycerol solution for 24 hours, plasticize the regenerated cellulose hydrogel, soak the plasticized hydrogel in liquid nitrogen ( -170°C) for 1-2 minutes, and then carry out vacuum freeze-drying for 12 hours to obtain regenerated cellulose airgel; during vacuum freeze-drying, the drying temperature is -20°C--55°C, and the vacuum degree during drying is 5-50Pa .

[0058] Comparative example one of embodimen...

Embodiment 2

[0070] (1) Place the regenerated cellulose airgel prepared in Example 1 in a vacuum oven at 40°C and dry for 48 hours;

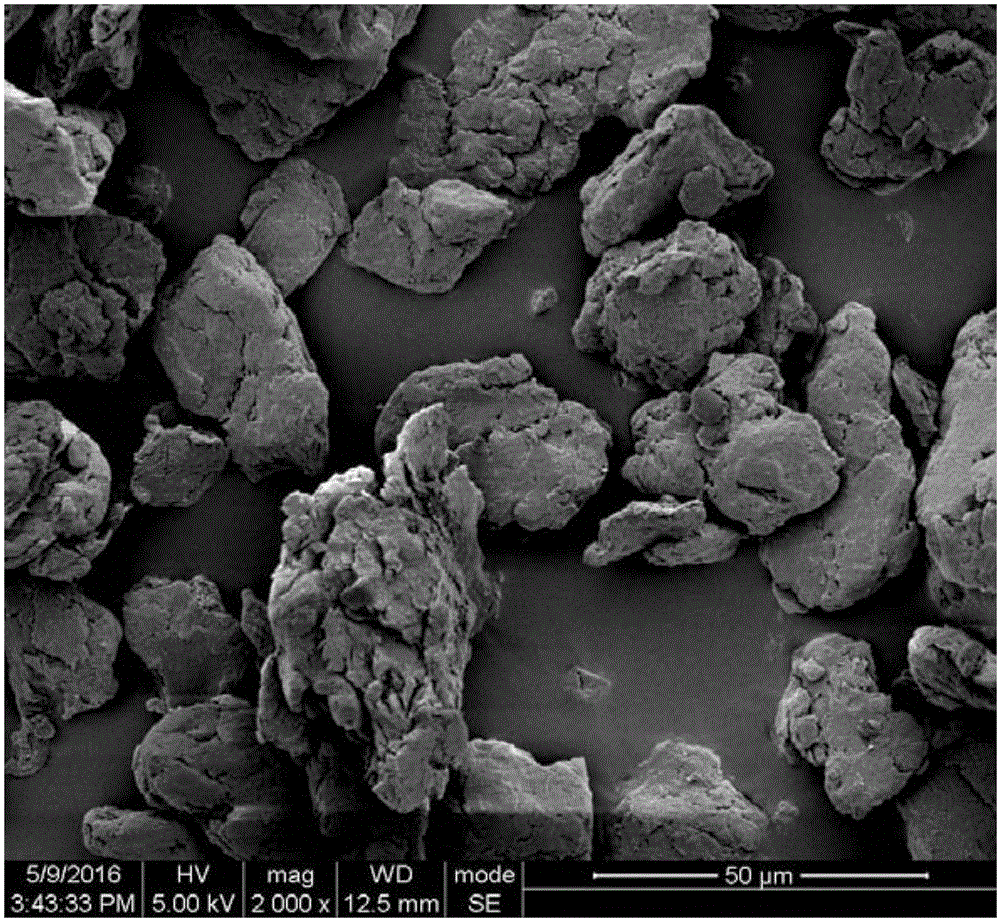

[0071] (2) Add a certain proportion of regenerated cellulose airgel, lactide, and stannous octoate into the dried high-pressure reactor; after the sealing work is done, enter atmospheric carbon dioxide for gas replacement, and drain the reactor Inner air; the amount of regenerated cellulose airgel is 12.5% of the mass of lactide, and the amount of stannous octoate is 1% of the mass of lactide;

[0072] (3) After the gas replacement is completed, at room temperature T 0 A certain amount of high-pressure carbon dioxide is passed into the reactor under the condition that the pressure is P 0 , P 0 is given by the preset reaction pressure P 1 and preset reaction temperature T 1 by formula Calculated; the carbon dioxide reaches a supercritical state by raising the temperature of the reactor, and then reacts; the reaction temperature T 1 =120°C, reaction p...

Embodiment 3

[0093] (1) Place the regenerated cellulose airgel prepared in Example 1 in a vacuum oven at 40°C and dry for 48 hours;

[0094] (2) Add a certain proportion of regenerated cellulose airgel, lactide, and stannous octoate into the dried high-pressure reactor; after the sealing work is done, enter atmospheric carbon dioxide for gas replacement, and drain the reactor Inner air; the amount of regenerated cellulose airgel is 25% of the mass of lactide, and the amount of stannous octoate is 1% of the mass of lactide;

[0095] (3) After the gas replacement is completed, at room temperature T 0 A certain amount of high-pressure carbon dioxide is passed into the reactor under the condition that the pressure is P 0 ;P 0 is given by the reaction pressure P 1 and reaction temperature T 1 by formula Calculated; by raising the temperature of the reactor to make it reach a supercritical state, and then react; the reaction temperature T 1 =120°C, reaction pressure P 1 =22MPa, the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com