Compressed expanded graphite thermal conductive composite material, and preparation method thereof

A technology of compression expansion and graphite heat conduction, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of compression and expansion graphite heat conduction network damage, affecting heat conduction performance, etc., to improve heat conduction performance, excellent performance, protection and heat conduction performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A thermally conductive composite material of compressed and expanded graphite, comprising compressed and expanded graphite, phenolic resin and silicon rubber, the volume percentage of the silicone rubber is 36%, the volume percentage of the compressed and expanded graphite is 59%, and the phenolic The volume percentage of resin is 5%.

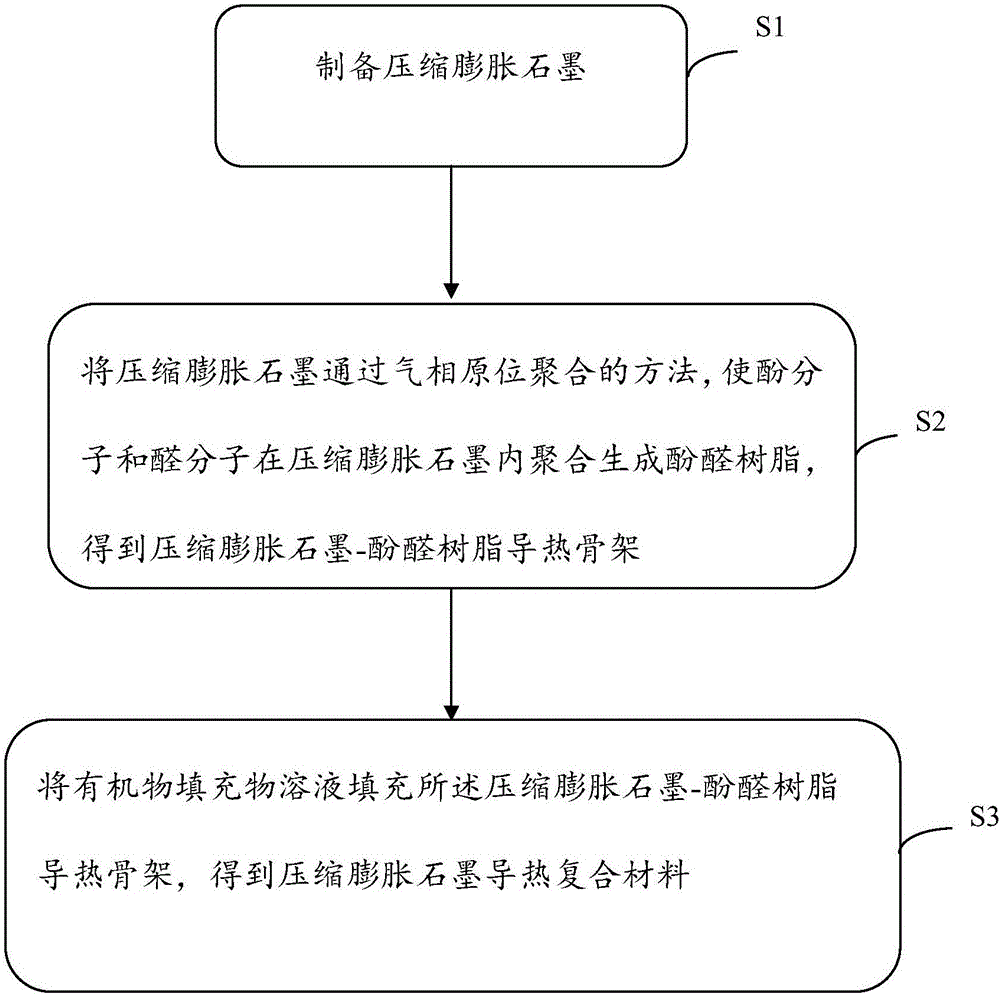

[0049] see figure 1 , a method for preparing a thermally conductive composite material of compressed expanded graphite, comprising the steps of:

[0050] S1, preparing compressed expanded graphite;

[0051] The graphite was oxidized by strong acid intercalation, and then expanded in a microwave oven for 20 seconds to obtain expanded graphite.

[0052] The expanded graphite is weighed, and the expanded graphite is compressed by unidirectional pressure in a mold to obtain compressed expanded graphite. The density of compressed expanded graphite described in the present embodiment is 0.1g / cm 3 . The compressed expanded graphite include...

Embodiment 2

[0061] A kind of compressed expanded graphite heat-conducting composite material, comprising compressed expanded graphite, phenolic resin and paraffin, the volume percent of described paraffin is 94.9%, the volume percent of described compressed expanded graphite is 5%, the phenolic resin The volume percentage is 0.1%.

[0062] The preparation method of the thermally conductive composite material of compressed expanded graphite includes the following steps: put the expanded graphite into a beaker, heat it in a high-temperature furnace at 800°C for 30s to expand the graphite into expanded graphite, weigh an appropriate amount of expanded graphite powder with a balance and put it in a stainless steel mold , unidirectionally compress and expand graphite to obtain a density of 0.05g / cm 3 compressed expanded graphite.

[0063] Place the compression-expandable graphite above the cresol and acetaldehyde, and heat it to 60°C. The cresol and acetaldehyde will be heated to evaporate cr...

Embodiment 3

[0066] A thermally conductive composite material of compressed and expanded graphite, comprising compressed and expanded graphite, phenolic resin and epoxy resin, the volume percentage of the epoxy resin is 73%, and the volume percentage of the compressed and expanded graphite is 25%, so The volume percentage of the phenolic resin is 2%.

[0067] The preparation method of the above-mentioned heat-conducting composite material of compressed expanded graphite comprises the following steps: put the expanded graphite in a beaker, heat it in a microwave oven for 10 seconds to expand the graphite into expanded graphite, weigh an appropriate amount of expanded graphite powder with a balance and put it in a stainless steel mould, Expand graphite towards compression to obtain a density of 0.5g / cm 3 compressed expanded graphite.

[0068] Put the compressed expanded graphite above the xylenol and furfural and heat it to 70°C. The xylenol and furfural are heated to evaporate cresol vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com