Process for enzymatic preparation of chiral 3-hydroxytetrahydrofuran and alcohol dehydrogenase mutant

A technology of hydroxytetrahydrofuran and ketotetrahydrofuran, which is applied in the field of enzymatic preparation of chiral 3-hydroxytetrahydrofuran and alcohol dehydrogenase mutants, can solve the problem of high conversion rate and achieve low environmental pollution, high purity and conversion rate and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

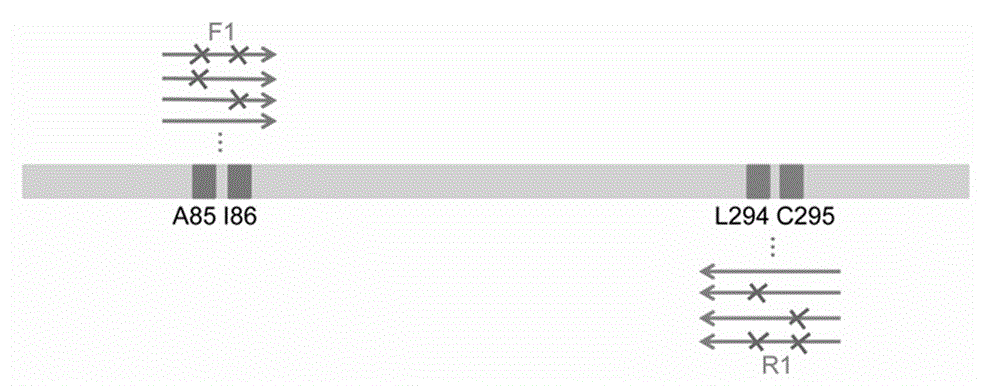

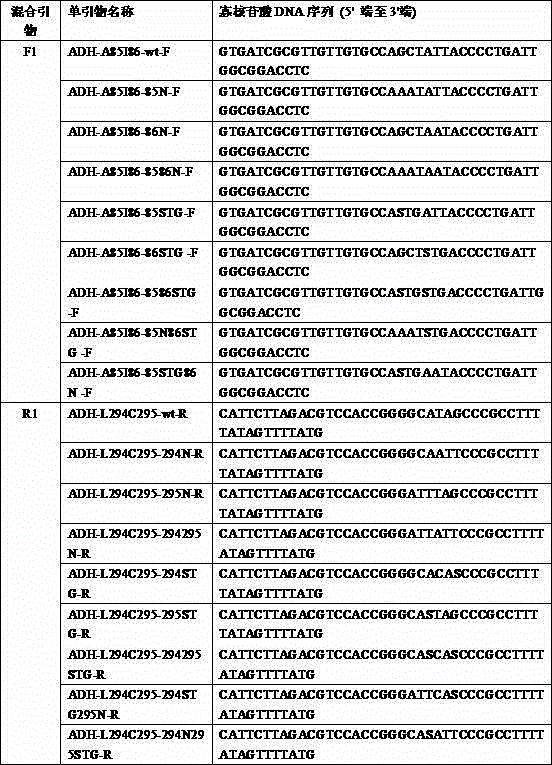

[0063] In the reaction system, the pH value is 7.0, the concentration is 50 mmol / L, phosphate buffer, 5mmol / L 3-ketotetrahydrofuran as the substrate and the final concentration is 10% isopropanol, 0.01mmol / L NAD + React with the crude enzyme solution of alcohol dehydrogenase mutant A85V / I86N / L294V / C295N at 30°C for 14-16 hours, extract the product and substrate with ethyl acetate and detect the reaction process with GC, measure the ee value and Conversion rate; the product is (R )-3-Hydroxytetrahydrofuran, the ee value is 97%, and the conversion rate reaches 97%.

Embodiment 2

[0065] In the reaction system, the pH value is 7.4, and the concentration is 100 mmol / L phosphate buffer solution, 5 mmol / L 3-ketotetrahydrofuran as the substrate and the final concentration is 10% isopropanol, 0.05 mmol / L L-NAD + As a cofactor and I86N / C295N alcohol dehydrogenase mutant crude enzyme solution, react at 25°C for 14-16 hours, extract the product and substrate with ethyl acetate and use GC to detect the reaction process, measure the ee value and conversion rate , the product is ( R )-3-hydroxytetrahydrofuran, the ee value is 99%, and the conversion rate is 99%.

Embodiment 3

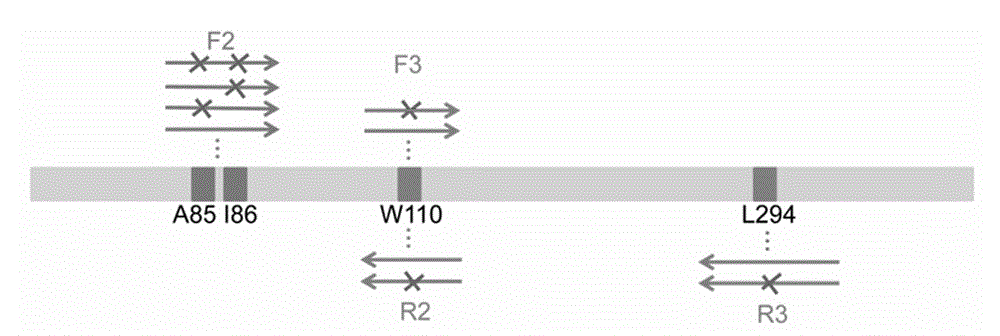

[0067] In the reaction system, add phosphate buffer solution with a pH value of 7.4 and a concentration of 50mmol / L, 5mmol / L 3-ketotetrahydrofuran as a substrate and isopropanol with a final concentration of 10%, 0.01~0.1 mmol / LNADP + As a cofactor and I86V / W110L / L294Q alcohol dehydrogenase mutant lysate, react at 30°C for 14-16 hours, extract the product and substrate with ethyl acetate and use GC to detect the reaction process, determine the ee value and conversion rate; the product is ( S )-3-hydroxytetrahydrofuran, the ee value is 95%, and the conversion rate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com