Glass fiber reinforced polyethylene water feed pipe

A technology for polyethylene and water supply pipes, which is applied in the direction of pipes, rigid pipes, tubular objects, etc., and can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

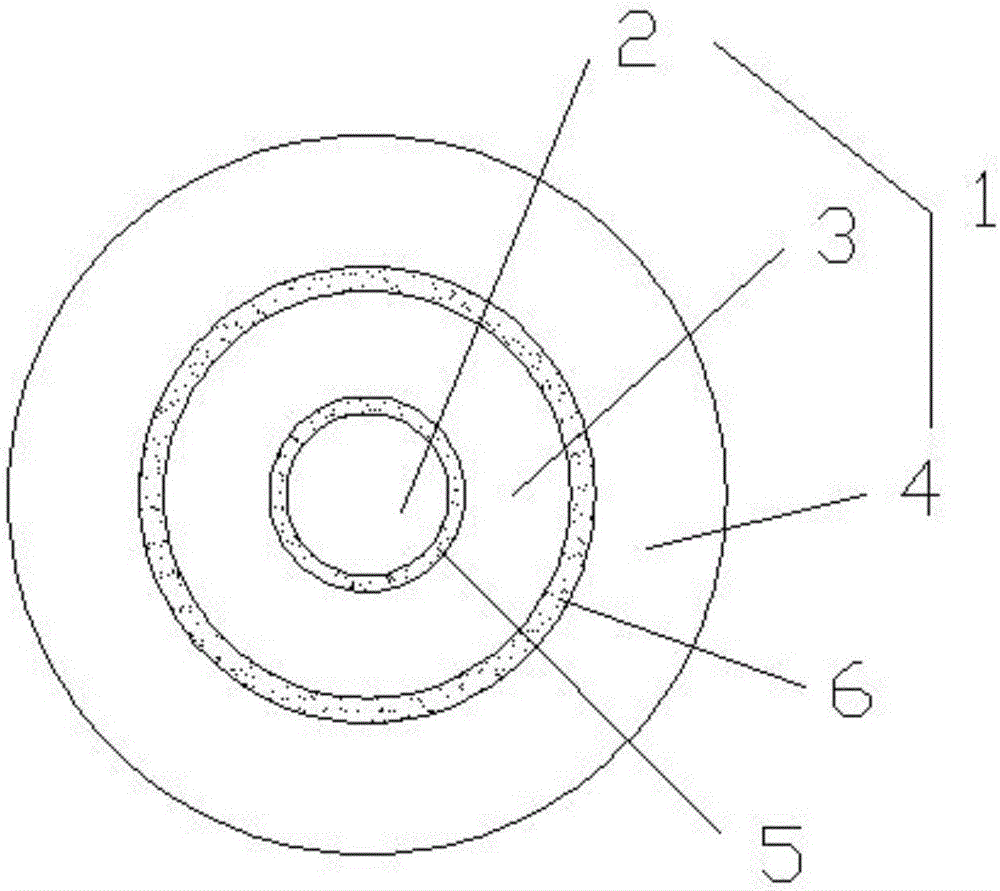

[0023] Please refer to figure 1 , a glass fiber reinforced polyethylene water supply pipe, including a pipe body 1, the pipe body is composed of an inner layer 2, a core layer 3 and an outer layer 4, the core layer 3 and the outer layer 4 are HDPE materials, and the inner layer 2 The material is glass fiber cloth, an inner transitional connection layer 5 is provided between the inner layer 2 and the core layer 3, and an outer transitional connection layer 6 is provided between the outer layer 4 and the inner layer 2;

[0024] It includes a pipe body 1. The pipe body is composed of an inner layer 2, a core layer 3 and an outer layer 4. Both the inner layer 2 and the outer layer 4 are made of HDPE, and the material of the core layer 3 is wound pretreated glass. For the fiber tape layer, an inner transitional connection layer 5 is provided between the inner layer 2 and the core layer 3 , and an outer transitional connection layer 6 is provided between the outer layer 4 and the in...

Embodiment 2

[0030] (The structure of the pipe body is the same as in Example 1) wherein the parts by weight of the raw materials of the pipe body are: 91.2 parts of HDPE, 2.1 parts of coupling agent, and 17.2 parts of glass fiber. The parts by weight of the raw materials of the inner and outer transitional connection layers are: 0.6 parts of coupling agent, 1.4 parts of poly(methacryloyloxyethyl ammonium chloride-hydroxyalkyl acrylate) copolymer, 0.3 parts of polypropylene resin, processing lubricant 0.57 parts of the agent.

[0031] The coupling agent is a surface coupling agent, and the surface coupling agent is one of titanate, aluminate, silanes, grafted maleic anhydride and its derivatives, vinyl silane, acrylates and their derivatives or more.

[0032] The processing lubricant is one or more mixtures of paraffin wax, polyethylene wax, polypropylene wax, stearic acid, stearic acid metal salt and ethylene acrylic acid copolymerized metal salt.

[0033] Its preparation process is as ...

Embodiment 3

[0035] (The structure of the pipe body is the same as in Example 1) The parts by weight of the raw materials of the pipe body are: 93.5 parts of HDPE, 3.7 parts of coupling agent, and 20.5 parts of glass fiber. The parts by weight of the raw materials of the inner and outer transitional connection layers are: 0.6 parts of coupling agent, 2.9 parts of poly(methacryloyloxyethylammonium chloride-hydroxyalkyl acrylate) copolymer, 0.4 part of polypropylene resin, processing lubricant 0.63 parts of the agent.

[0036] The coupling agent is a surface coupling agent, and the surface coupling agent is one of titanate, aluminate, silanes, grafted maleic anhydride and its derivatives, vinyl silane, acrylates and their derivatives or more.

[0037] The processing lubricant is one or more mixtures of paraffin wax, polyethylene wax, polypropylene wax, stearic acid, stearic acid metal salt and ethylene acrylic acid copolymerized metal salt.

[0038] Its preparation process is as follows: u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com