Method for determining full-pore-diameter pore structure of coal through multi-data fusion

A pore structure and measurement method technology, which is applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve problems such as difficult to achieve, the vacuum system cannot meet the measurement requirements, and the measurement of pore structure parameters is unreliable. The effect of increasing reliability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following structural specific examples further illustrate the present invention, but the protection scope of the present invention is not limited thereto.

[0040] A method for measuring coal full-diameter pore structure multi-data fusion, comprising the following steps:

[0041] ① The coal pore structure was measured by carbon dioxide adsorption method, liquid nitrogen adsorption method and mercury porosimetry;

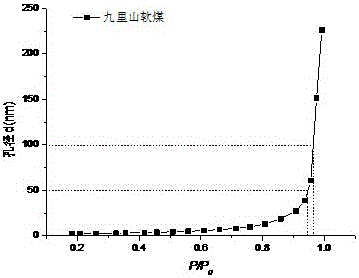

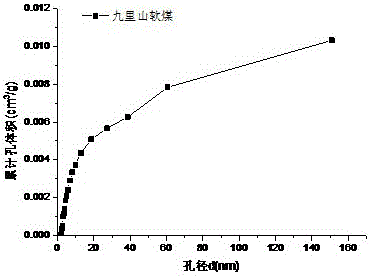

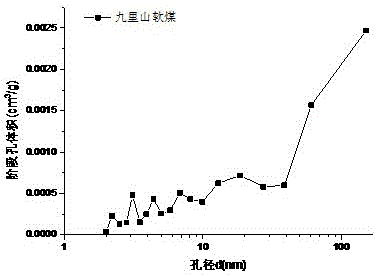

[0042] ② Take the pore structure in the coal pore structure measured by the carbon dioxide adsorption method in the range of 100nm The pore structure in the coal can be obtained, so as to obtain the pore structure in the full pore diameter range of coal.

[0043] The coal pore structure is any one or both of specific surface area and pore volume.

[0044] The steps of the carbon dioxide adsorption method are as follows:

[0045] ①Crush the coal sample to less than 10mm, put it into the sample container, heat it in vacuum at 150℃ for 4 hours, and cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com