Method for detecting whether diesel oil in diesel oil pump leaks into lubricating oil

A lubricating oil and diesel pump technology, applied in the field of analytical chemistry, can solve problems such as not particularly effective and timely methods, metal wear, unstable metal ion content, etc., and achieve the effect of improving specificity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

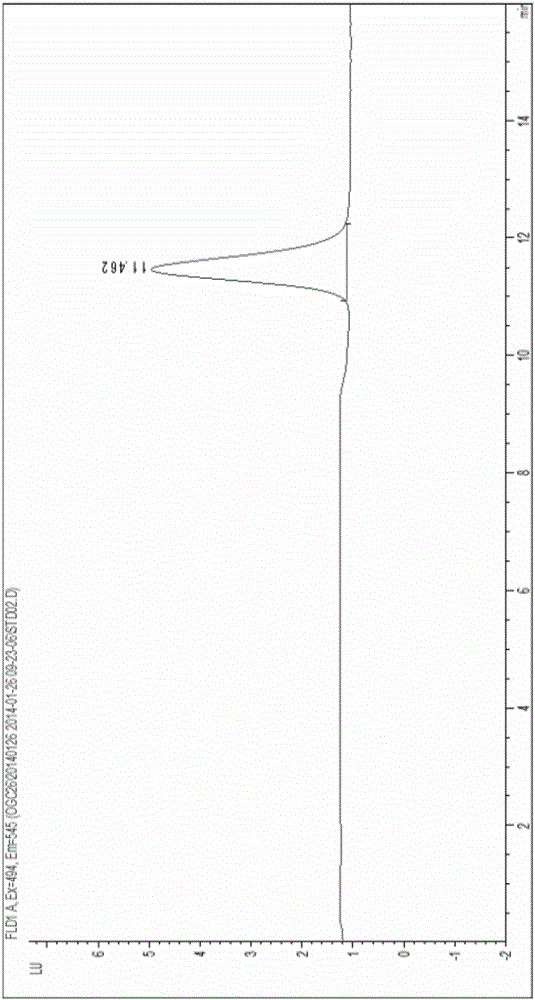

[0027] Example 1: Monitoring diesel oil leakage from high-pressure diesel pumps

[0028] 1) Accurately mix Fluorescent Yellow 131SC fluorescent agent into the diesel oil used, the content of Fluorescent Yellow 131SC fluorescent agent is 2g / kg. Monitor the normal operation of the high-pressure diesel pump for a period of time.

[0029] 2) Take 1g of lubricating oil sample from diesel pump lubricating oil, add n-hexane to dilute to 10mL, take 10uL for liquid chromatography analysis.

[0030] 3) Instrument parameters of liquid chromatography fluorescence detector

[0031] Chromatographic column: ZORBAX XDB C18 2.5mm*46mm (or similar chromatographic column)

[0032] Column temperature: 40°C

[0033] Column flow rate: 1.0mL / min

[0034] Injection volume: 10μL

[0035] Mobile phase: methanol + tert-butyl methyl ether = 10 + 90

[0036] Analysis time: 20min

[0037] The wavelength of the fluorescence detector is set as follows: the excitation wavelength is 494nm, and the emiss...

Embodiment 2

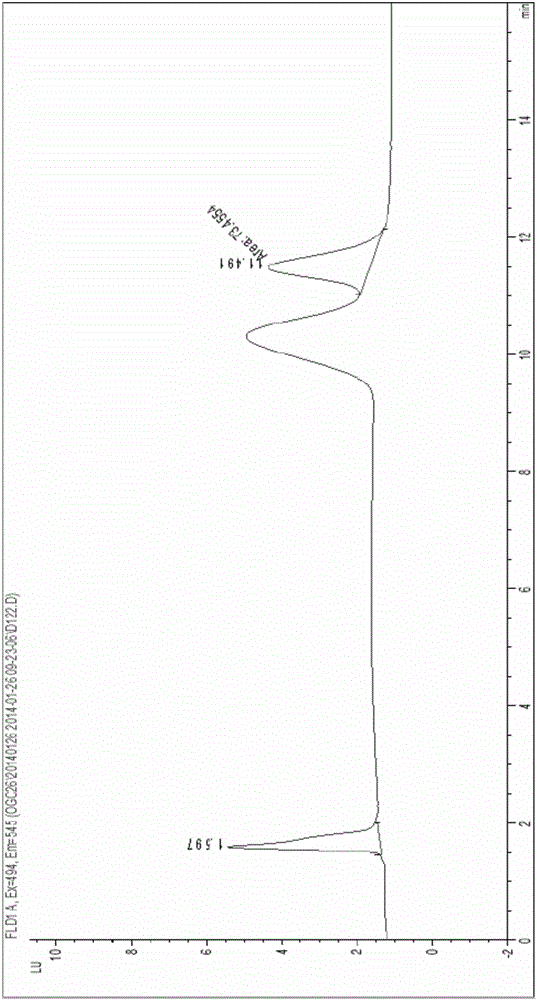

[0040] Example 2: Monitoring diesel oil leakage from high-pressure diesel pumps

[0041] 1) Accurately mix Fluorescent Yellow 131SC fluorescent agent into the diesel oil used, so that the content of Fluorescent Yellow 131SC fluorescent agent is 5g / kg. Monitor the normal operation of the high-pressure diesel pump for a period of time.

[0042] 2) Take 1g of lubricating oil sample from diesel pump lubricating oil, add n-hexane to dilute to 10mL, take 10uL for liquid chromatography analysis.

[0043] 3) Instrument parameters of liquid chromatography fluorescence detector

[0044] Chromatographic column: ZORBAX XDB C18 2.5mm*46mm (or similar chromatographic column)

[0045] Column temperature: 40°C

[0046] Column flow rate: 1.0mL / min

[0047] Injection volume: 10μL

[0048] Mobile phase: methanol + tert-butyl methyl ether = 10 + 90

[0049] Analysis time: 20min

[0050] The wavelength settings of the fluorescence detector are: the excitation wavelength is 494nm, and the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com