Zero-flux micro-current sensor used for leakage current detection

A micro-current sensor, leakage current technology, applied in the direction of measuring current/voltage, instruments, measuring devices, etc., can solve the problem of not mentioning the positive effect of the specific compensation scheme of zero magnetic flux, lack of weak signal processing unit, complex implementation and other problems , to achieve good anti-electromagnetic interference ability, improve load characteristics, and meet measurement requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the purpose, technical solutions and advantages of the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

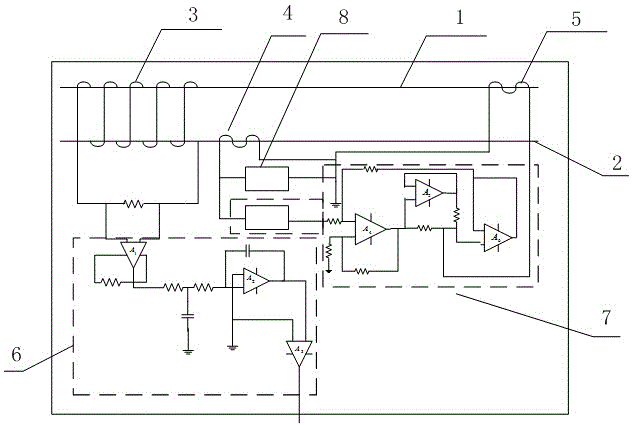

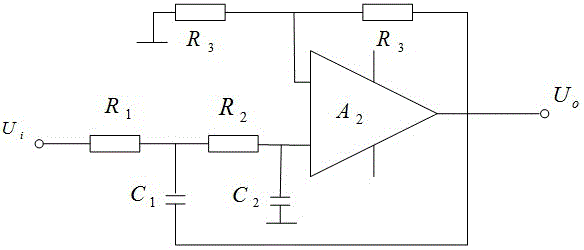

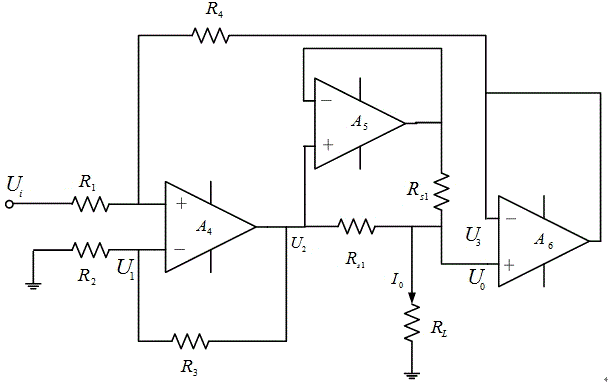

[0020] Implement a zero-flux microcurrent sensor for leakage current detection, the sensor is a zero-flux current sensor for measuring power frequency microampere to milliampere level current, including a signal sensing unit, a signal processing circuit, Signal compensation circuit and shielding unit. Its composition is that the signal induction unit is composed of two identical ring-shaped main cores 1, auxiliary cores 2, secondary windings 3, detection windings 4, and compensation windings 5; the signal processing circuit 6 includes a differential amplifier circuit, a low-pass Bart Voss type filter circuit and post-amplification circuit; signal compensation circuit is divided into active compensation circuit 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com