Monolith

A pre-material and solvent technology, which is applied in the field of providing monoliths with multiple channels and filtering water, which can solve problems such as lack of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

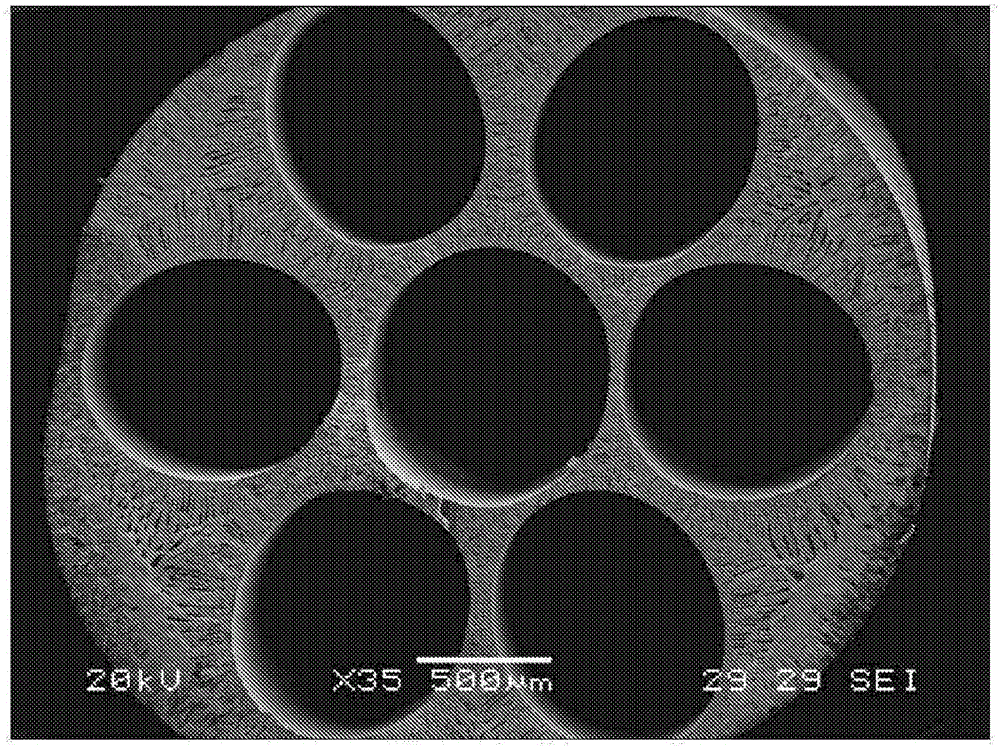

[0080] Porous ceramic monoliths were prepared as follows. The suspension was prepared using: alumina (60 wt%) with an average particle diameter of 1 micron, DMSO (33.6 wt%) as solvent, and PESf (6 wt%) as polymer binder, and Arlacel as dispersant P135 (polyethylene glycol 30-dipolyhydroxystearate, Uniqema) (0.4 wt%).

[0081] This suspension was extruded through a 7-channel spinneret at a rate of 7 ml / min, a water flow rate of 12 ml / min and an air gap of 0.5 cm. This forms a 7-channel monolith, which is then sintered at 1350°C. Then the fracture load (fracture loading) of this sample was tested, and the results were as follows:

[0082]

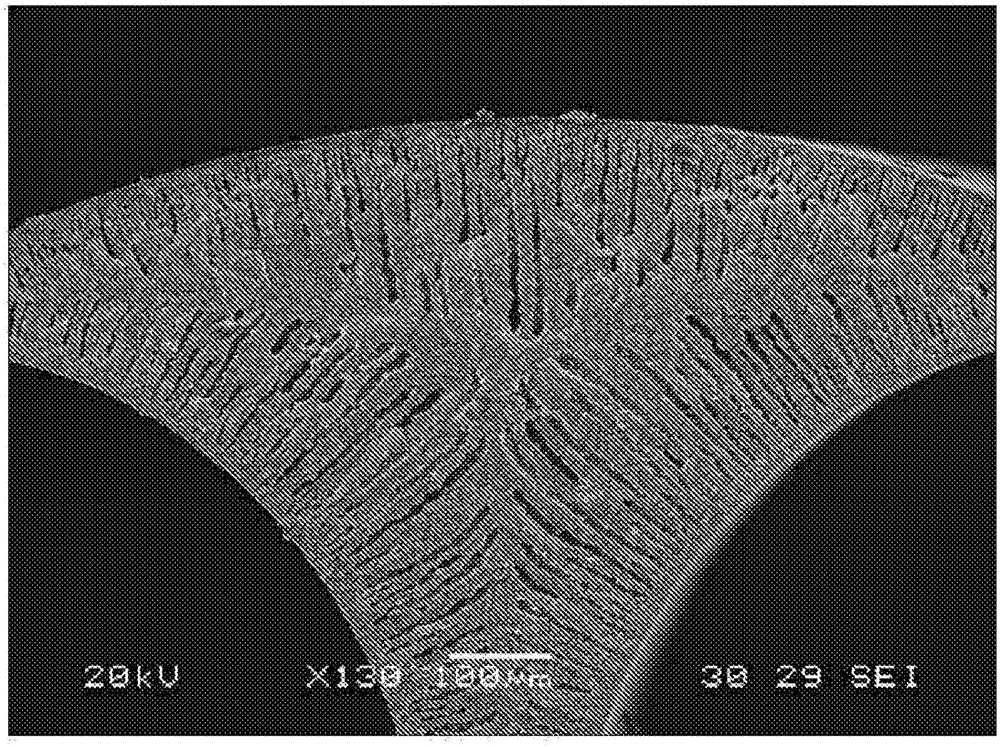

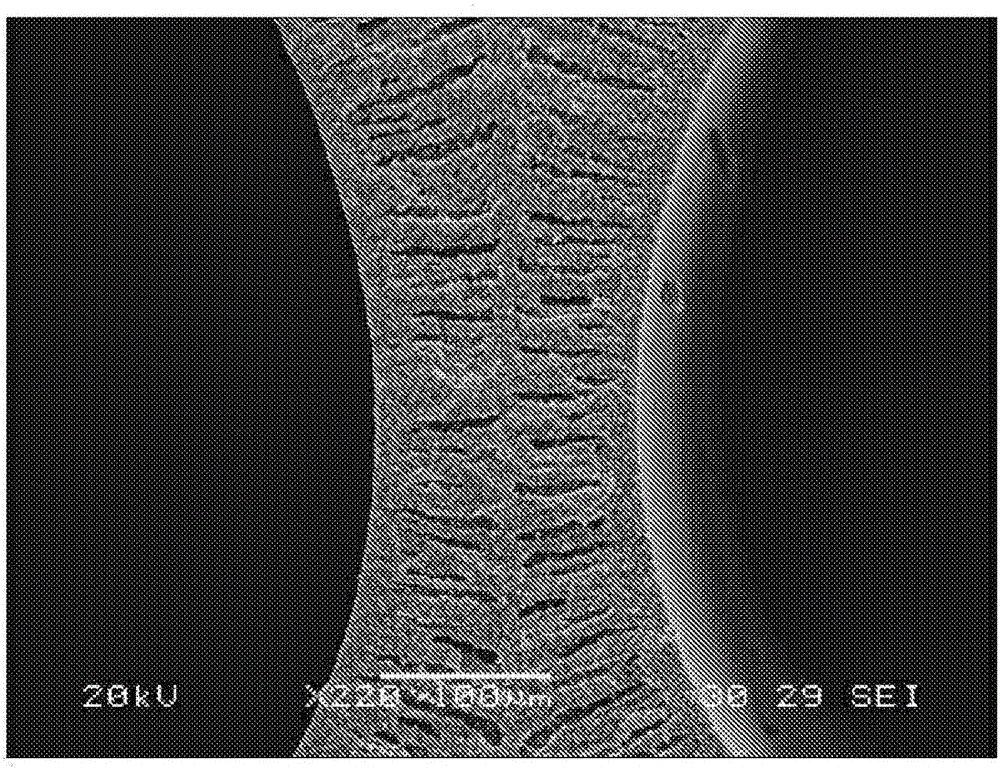

[0083] The as-prepared structure was investigated with SEM. The product was found to be a uniform 7-channel hollow fiber. The structure is self-organized microchannels throughout the fibers with spongy layers between microchannel layers. In addition, there is a skin-like spongy layer at the channel surface and outer surface, uniform c...

Embodiment 2

[0088] Porous ceramic monoliths were prepared as follows. The suspension was prepared using: 1 micron average particle diameter alumina (62 wt%), NMP (31.4 wt%) as solvent, PESf (6.2 wt%) as polymer binder, dispersant (0.4 wt%) .

[0089] This suspension was extruded through a 19-channel spinneret at a speed of 11 ml / min, water flow: 18 ml / min, and without air gaps. This forms a 19-channel monolith, which is then sintered at 1350°C. The breaking load of this sample was then tested, and the results were as follows:

[0090]

[0091] The mercury porosimetry profile shows a slightly more porous channel surface (0.55 microns) through which catalyst or adsorbent can be deposited, with another peak still at 0.18 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com