Temperature control agent, and heating composition, packaging material, and warming material each including same

A heat-generating composition and temperature control technology, which are applied in heat exchange materials, heating appliances for therapeutic treatment, cooling appliances for therapeutic treatment, etc., can solve the problem of uneven temperature, unstable temperature, disposable portable heating appliances High technical risk and other problems, to achieve the effect of low cost and excellent temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

[0087] As materials for the exothermic composition, iron powder (Model RDH-3M, Powertech Co., Ltd.), activated carbon (Model FY-1, Co., Ltd. Catara), vermiculite (Belumiteck Co., Ltd.), water-absorbing polymer ( Model ST-500D, Sanyo Chemical Industry Co., Ltd.), refined salt (Hingsalt, (Co., Ltd.) Nippon Seawater), water to make a basic compound heating composition.

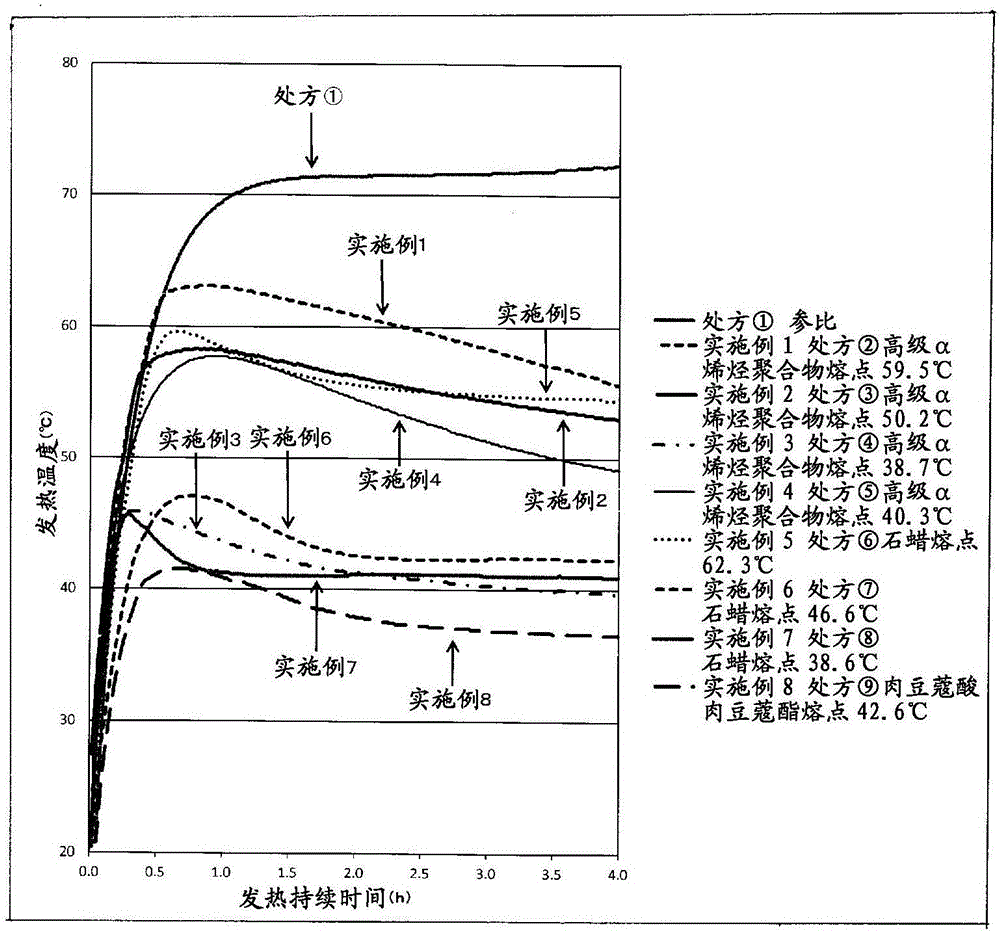

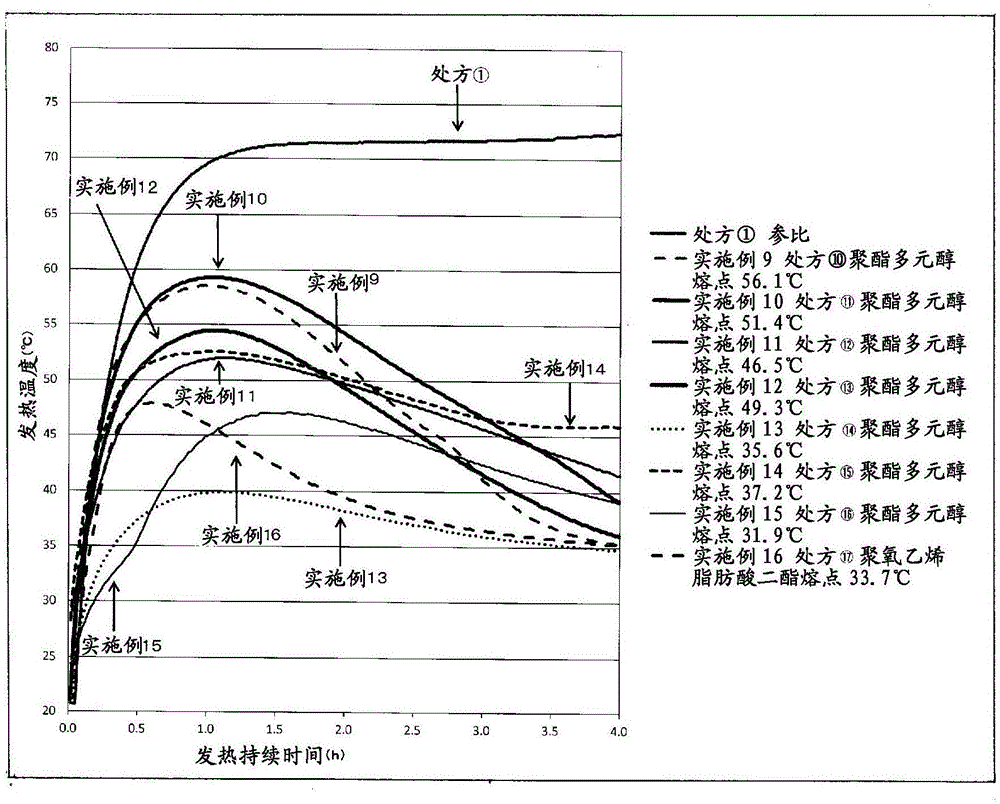

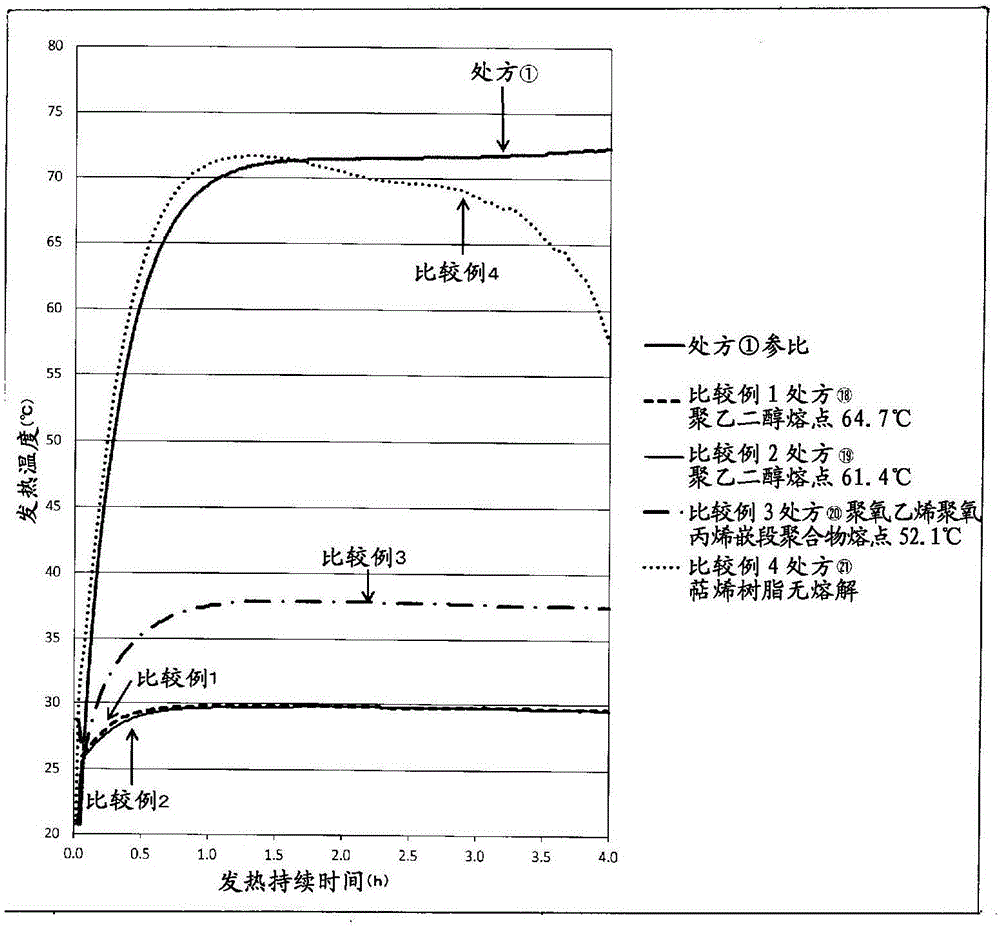

[0088] Various aliphatic compounds shown in Table 1 were used to prepare exothermic compositions, and warmers (disposable portable heaters) using these exothermic compositions were manufactured, and their exothermic properties were tested. The composition of the exothermic composition is shown in Table 2. (In the table, the unit of content is " weight part ".)

[0089] [Table 1]

[0090]

[0091] [Table 2]

[0092]

[0093] For each compound shown in Table 1, the granular compound was pulverized into powder with a mortar, and the lumpy compound was frozen in a freezer for 2 hours, and pulverized into pow...

Embodiment 17~18

[0098] As the exothermic composition, the composition basically formulated in Table 2 was used. The surface packing material is manufactured as follows. Use the temperature control agent of embodiment 17,18 (respectively identical with embodiment 5,3) to replace bonding agent, utilize hot-melt curtain spray method to carry out coating (10g / m 2 ), 35 g of polypropylene spunbonded nonwoven fabric (manufactured by Shinwa Co., Ltd.) and 70 μ thick polyethylene porous film (manufactured by Kohin Film & Chemicals Co., Ltd.) were bonded together. Cut into width 95mm x length 130mm, peel it off once by hand, spray synthetic rubber-based (styrene butadiene) spray paste (manufactured by Sumitomo Triem Co., Ltd.) to bond, and manufacture air permeability 9,000 seconds / 100cc (JISP8117) breathable sheet. The inner packaging material uses the same material as above. Disposable portable heaters were produced in the same manner as above, and a heat generation test was performed.

[0099] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| water solubility | aaaaa | aaaaa |

| water solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com