Super stable oxidation desulfurization catalyst, and preparation method and application thereof

A technology of oxidative desulfurization and catalyst, applied in the direction of physical/chemical process catalyst, chemical instrument and method, organic compound/hydride/coordination complex catalyst, etc. Eliminate problems such as falling off, and achieve the effects of improving catalytic activity, easy recycling, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of PTA@UiO-66

[0040] Hydrothermal method, using zirconium tetrachloride (699mg), terephthalic acid (498mg), phosphotungstic acid (1.44g) and DMF (60mL) as raw materials, ultrasonically treated for 20min to obtain a uniformly mixed solution, and heated at 120°C Insulated in an oven for 24 hours, the obtained solid was washed three times with water and ethanol, and dried overnight at 70°C in an oven to obtain 10% PTA@UiO-66. Among them, 10% is the percentage of phosphotungstic acid in the total mass of the catalyst.

[0041] (2) Preparation of blank material UiO-66

[0042] Hydrothermal method, using zirconium tetrachloride (699mg), terephthalic acid (498mg) and DMF (60mL) as raw materials, ultrasonically treated for 20min to obtain a mixed solution, and kept in an oven at 120°C for 24h, the obtained solid After washing with water and ethanol three times each, and drying in an oven at 70°C overnight, UiO-66 was obtained.

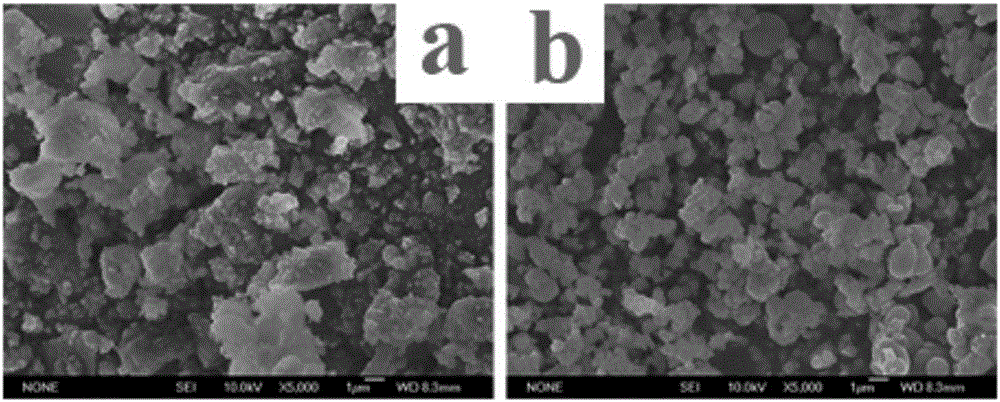

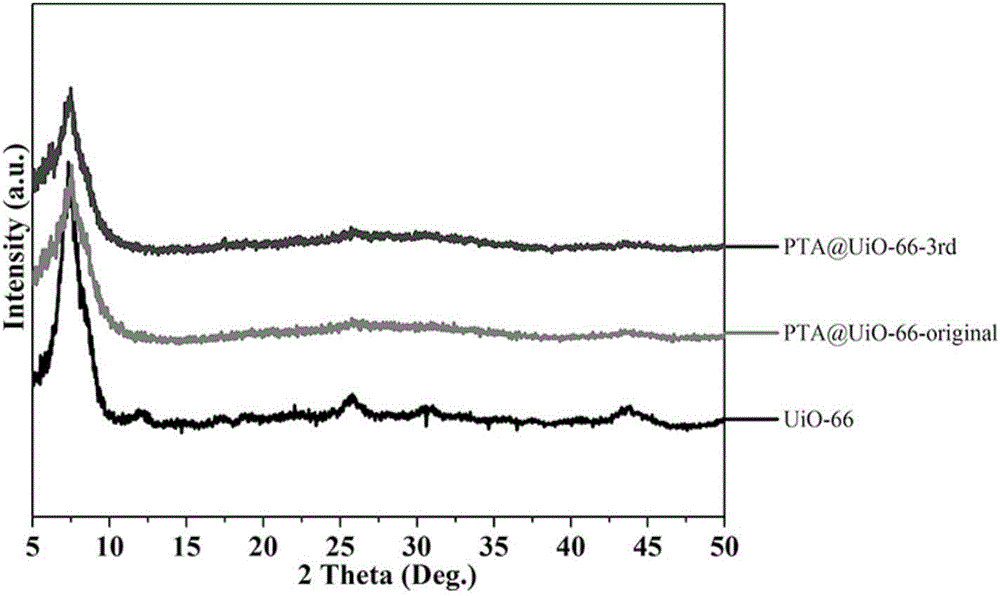

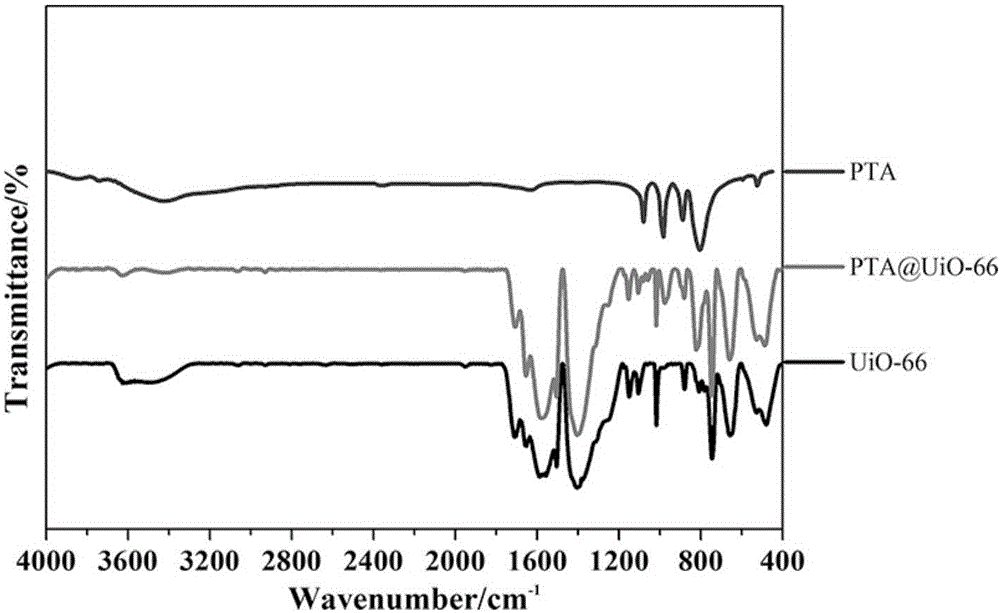

[0043] The morphology of PTA...

Embodiment 2

[0045] Performance evaluation of extraction catalytic oxidation desulfurization of PTA@UiO-66 catalyst:

[0046](1) The effect of the molar ratio of hydrogen peroxide to organic sulfur (O / S) on the catalytic activity. Dibenzothiophene was selected as the probe molecule to study the oxidative desulfurization performance of the catalyst. Take 2 mL of a dibenzothiophene / n-heptane mixed solution with a sulfur content of 1000 mass ppm and place it in a reaction tube, then add 2 mL of acetonitrile, and then add 46 mg of catalyst PTA@UiO-66. Add 0, 20, 30, 40, 50, 60 μL of hydrogen peroxide, that is, the O / S ratio is 0, 4, 6, 8, 10, 12, put it in an air bath reaction mold at 70°C and start heating, and after 0.5 hours, the transformation The rates were 0%, 63%, 82%, 93%, 95%, and 99%.

[0047] (2) Effect of reaction time on catalytic activity. Keeping the reaction conditions of step (1) unchanged, change the reaction time, under the condition of O / S ratio of 0, 4, 6, 8, 10, 12, af...

Embodiment 3

[0051] Evaluation of extraction catalytic oxidation desulfurization performance of UiO-66 catalyst:

[0052] (1) The effect of the molar ratio of hydrogen peroxide to organic sulfur (O / S) on the catalytic activity. Dibenzothiophene was selected as the probe molecule to study the oxidative desulfurization performance of the catalyst. Take 2 mL of a dibenzothiophene / n-heptane mixed solution with a sulfur content of 1000 mass ppm and place it in a reaction tube, then add 2 mL of acetonitrile, and then add 46 mg of catalyst UiO-66. Add 0, 20, 30, 40, 50, 60 μL of hydrogen peroxide, that is, the O / S ratio is 0, 4, 6, 8, 10, 12, put it in an air bath reaction mold at 70°C and start heating, and after 0.5 hours, the transformation Rates were 0%, 64%, 75%, 81%, 86%, and 88%.

[0053] (2) Effect of reaction time on catalytic activity. Keeping the reaction conditions of step (1) unchanged, change the reaction time, under the condition of O / S ratio of 0, 4, 6, 8, 10, 12, after 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com