Inoculant for degrading aflatoxin B1 and applications thereof

A technology of aflatoxin and bacterial agent, applied in the direction of bacteria, microbe-based methods, microbes, etc., can solve the problems of poor effectiveness, high cost, and lack of popularization and application, and achieve the effect of simple and easy operation in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

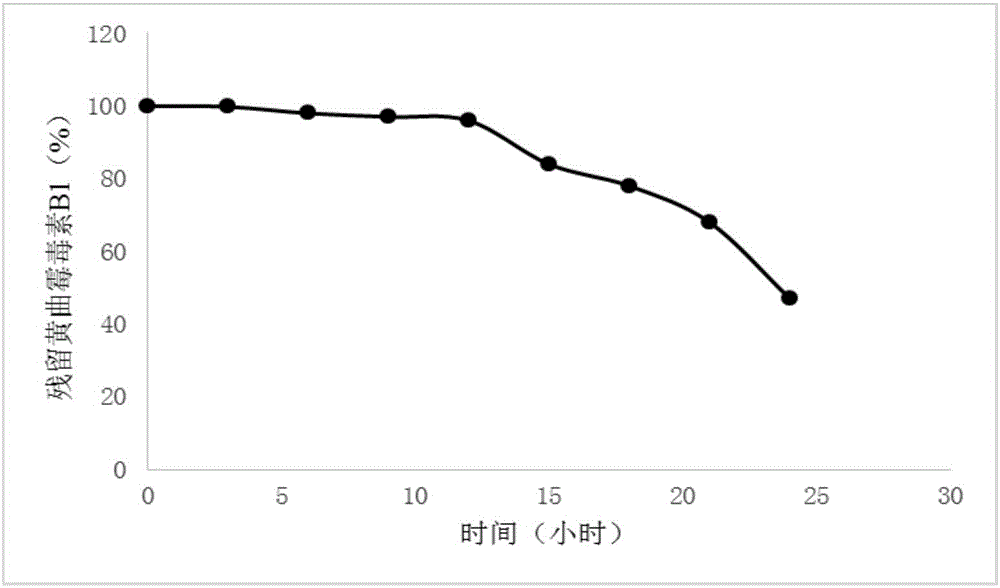

[0014] The preparation method of the bacterial agent for degrading aflatoxin B1:

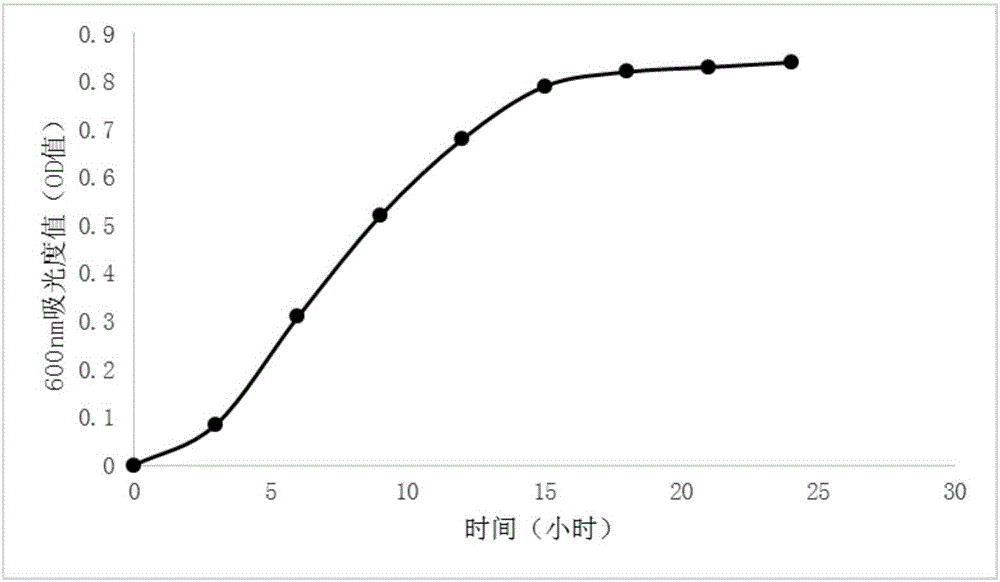

[0015] The Brevibacterium halotolerant JH8 (Shanghai Fuxiang Biotechnology Co., Ltd.) isolated or purchased from the soil was cultivated in nutrient broth NB520 (commercially purchased), and the cultivation was carried out in a shaker incubator, and the cultivation condition was that the speed was 150 rpm. Minutes, at a temperature of 30°C, and cultured for 18 hours to prepare a spray-type microbial agent.

[0016] Brevibacterium halotolerant JH8 is separated from the soil by the following method: take 2 grams of soil 12 to 15 centimeters below the surface of the soil layer, dissolve it in 20 milliliters of 0.9% sterile saline, shake it up, and centrifuge at 400 rpm for 90 minutes, take 100 μl of supernatant was spread on sterilized nutrient agar medium, and cultured at 30°C for 72 hours. A single colony was picked and repeatedly purified and cultured to obtain Brevibacterium halotolerant JH8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com