Preparation method of vanadium-doped nanometer tungsten oxide material and application of preparation method

A nano-tungsten oxide, tungsten hexachloride technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of insufficient attention on ion exchange performance, and achieve stable physical and chemical properties. , high porosity, and the effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

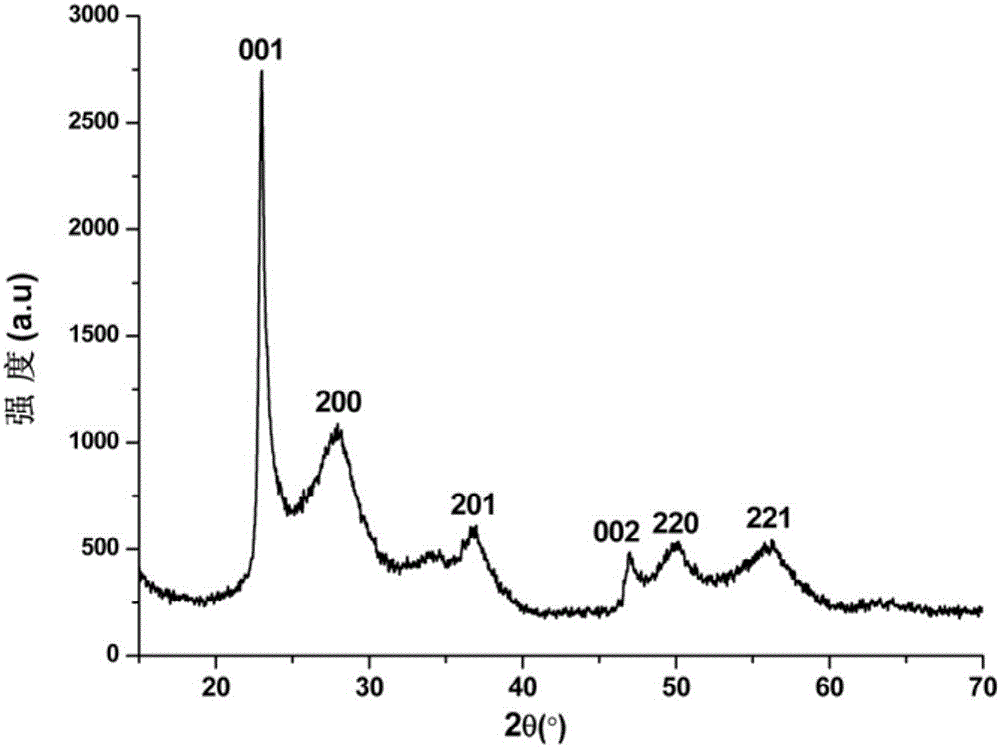

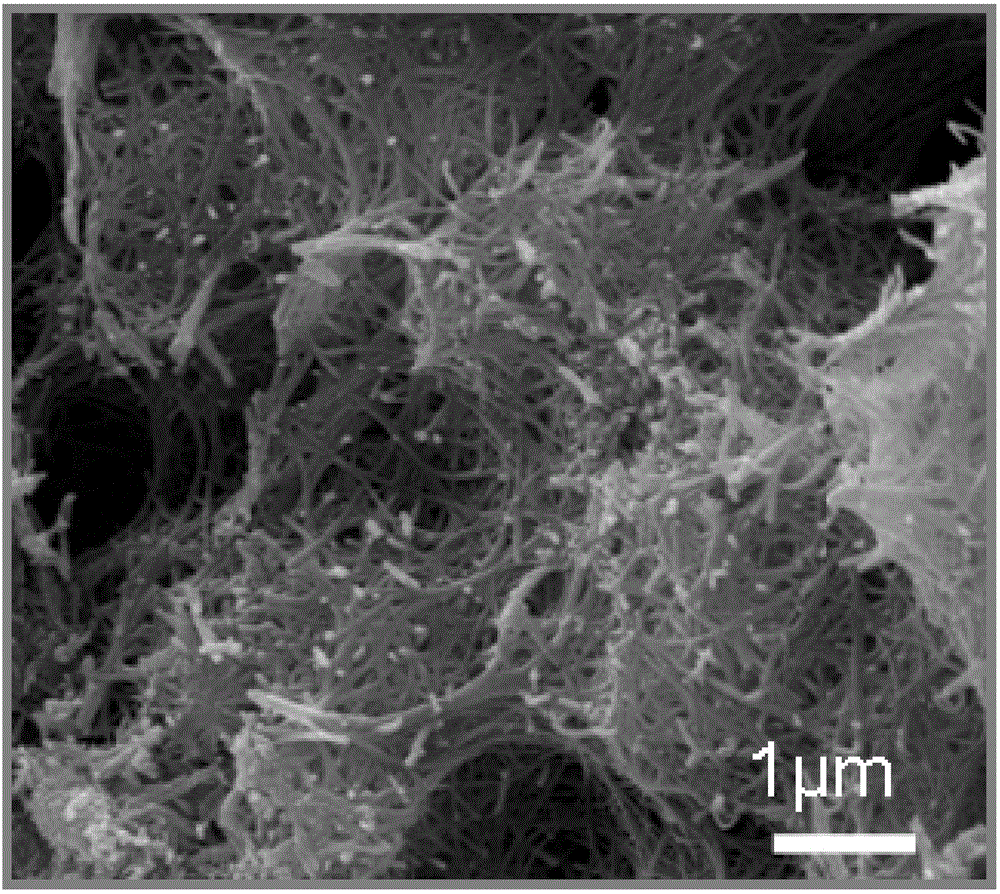

[0039] Put 8 parts of tungsten hexachloride solution with a concentration of 0.25mol / L in a polytetrafluoroethylene reactor, add 15 parts of twice distilled water, stir to make it fully dissolve, and then add 3mol / L hydrochloric acid solution to the above solution 3 parts and 30 parts of 0.5mol / L ammonium sulfate solution, stirred for 0.5h, sealed the polytetrafluoroethylene reactor, placed in a programmed oven, set the heating and cooling rate to 1°C / min, and hydrothermally treated at a temperature of 170°C for 24h. Take out the reaction kettle and cool it down to room temperature. Wash the reaction products with distilled water until they are neutral, and dry them in an oven at 80°C for 48 hours to obtain nano-tungsten oxide materials.

Embodiment 2

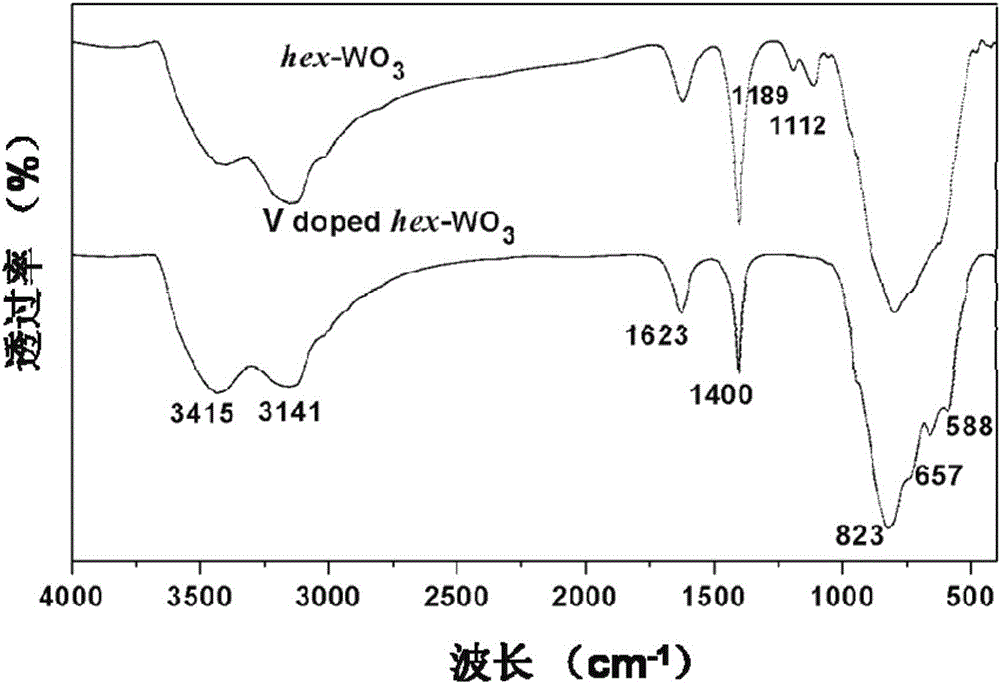

[0041] Put 8 parts of tungsten hexachloride solution with a concentration of 0.2mol / L in a polytetrafluoroethylene reactor, add 14 parts of twice distilled water, stir to make it fully dissolve, and add sodium metavanadate with a concentration of 0.18mmol / L 3 parts of the solution, continue to stir, and mix thoroughly; then add 3 parts of 3mol / L hydrochloric acid solution and 30 parts of 0.5mol / L ammonium sulfate solution to the above solution, stir for 0.5h, seal the polytetrafluoroethylene reactor, and put it in the program In the oven, set the heating and cooling rate to 1°C / min, and conduct a hydrothermal treatment at a temperature of 170°C for 48 hours. Take out the reactor and cool to room temperature. Wash the reaction products with distilled water until neutral, and dry them in an oven at a temperature of 80°C for 24 hours , to obtain vanadium-doped nano-tungsten oxide material.

Embodiment 3

[0043] Put 7 parts of tungsten hexachloride solution with a concentration of 0.25mol / L in a polytetrafluoroethylene reactor, add 13 parts of twice distilled water, stir to make it fully dissolve, and add sodium metavanadate with a concentration of 0.06mmol / L 4 parts of the solution, continue to stir, and mix thoroughly; then add 5 parts of 2mol / L hydrochloric acid solution and 31 parts of 0.5mol / L ammonium sulfate solution to the above solution, stir for 1h, seal the polytetrafluoroethylene reaction vessel, and place it in a programmed oven , set the heating and cooling rate to 1°C / min, and hydrothermally treat at 180°C for 24 hours. Take out the reactor and cool to room temperature. Wash the reaction products with distilled water until they are neutral, and dry them in an oven at 80°C for 24 hours to obtain Vanadium-doped nano-tungsten oxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com