Thioalcohol catalytic oxidation catalyst in light oil product and preparation method thereof

A light oil, catalytic oxidation technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of uneven distribution of active components, etc. Achieve good economic benefits and promotion value, not easy to lose, safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

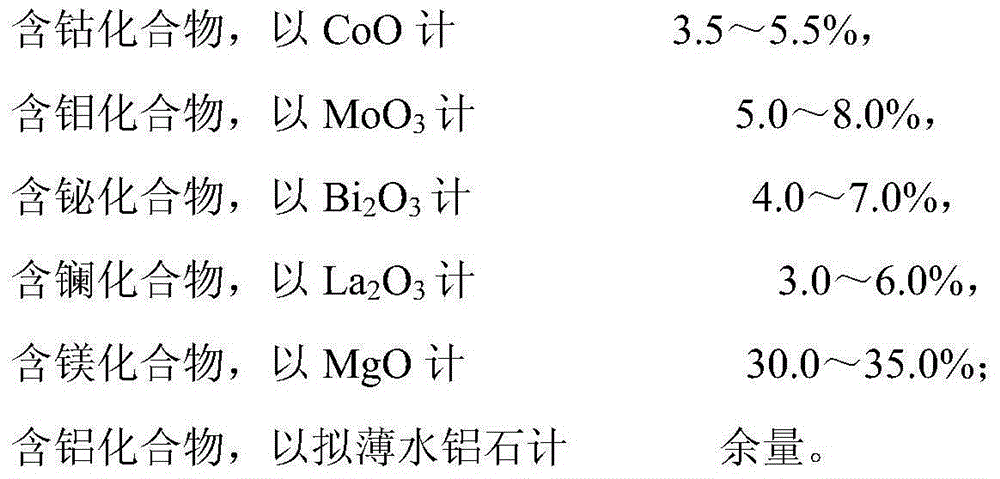

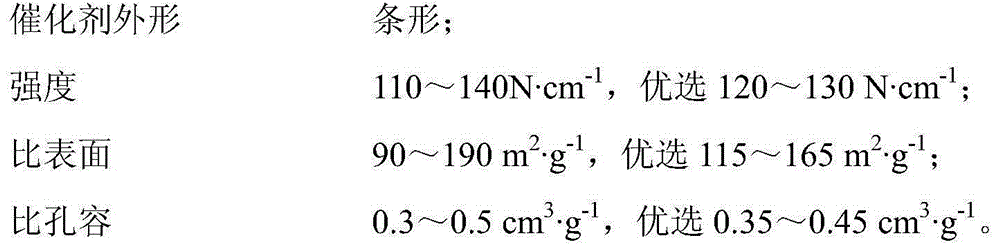

Method used

Image

Examples

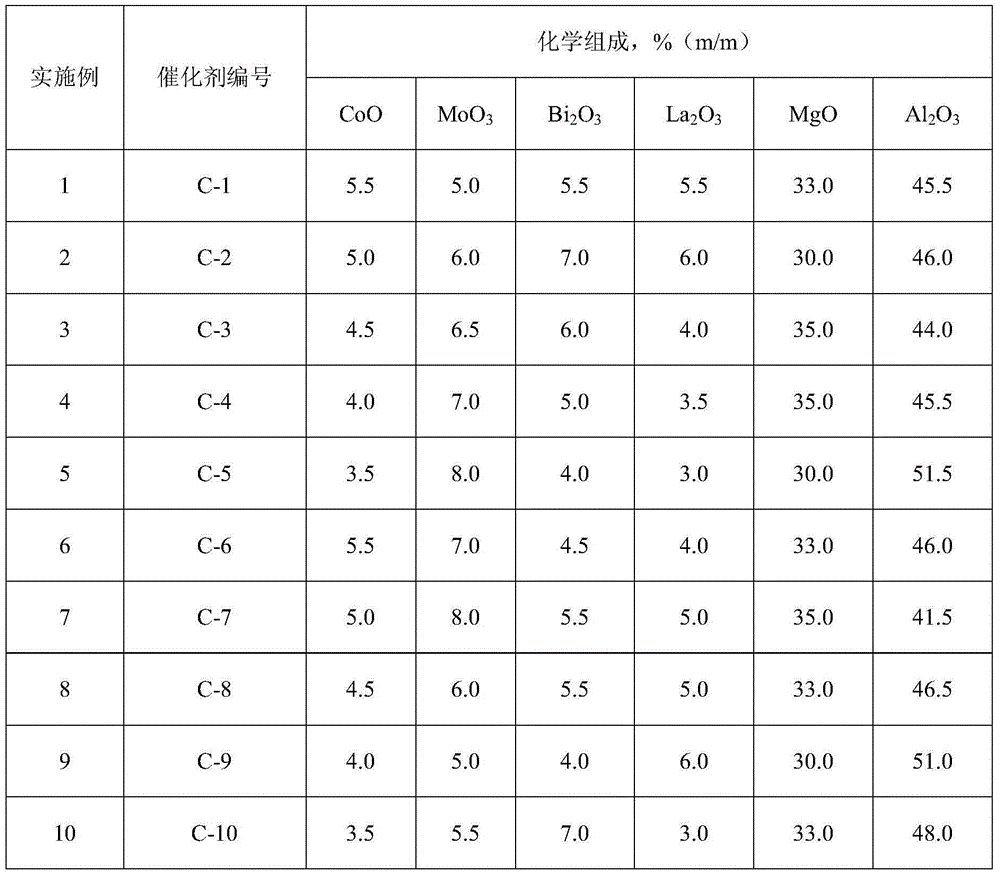

Embodiment 1

[0034] Catalyst C-1:

[0035] Weigh 122gMg(NO 3 ) 2 , 190gAl(NO 3 ) 3 , 21.30gCo(NO 3 ) 2 ·6H 2 O, 6.80g(NH 4 ) 2 ·MoO 4 , 11.50g Bi(NO 3 ) 3 ·5H 2 O, 14.60g La(NO 3 ) 3 ·6H 2 O, 6.00g citric acid was added to 200ml deionized water, mechanically stirred and heated to 70°C, and a solution A containing the four active components of cobalt, molybdenum, bismuth and lanthanum was prepared in one step.

[0036] Under vigorous stirring, the mass concentration of NaOH and Na 2 CO 3 The mixed solution and solution A are dropped into deionized water in a co-current manner, and the pH of the solution is maintained at 9.0±0.2. After full precipitation, the filter cake is transferred to the oxalic acid solution with a mass concentration of 1.5%. The filter cake is beaten and washed with vigorous stirring. The suction filter is repeated 3 times. The filter cake is dried at 80°C for 12 hours, and the dried catalyst is roasted. , 20°C is raised to 120°C in 1h and kept at 120°C for 1h; then it is r...

Embodiment 2

[0039] Catalyst C-2:

[0040] Weigh 111gMg(NO 3 ) 2 , 173gAl(NO 3 ) 3 , 19.40g Co(NO 3 ) 2 ·6H 2 O, 8.17g(NH 4 ) 2 ·MoO 4 , 14.60gBi(NO 3 ) 3 ·5H 2 O, 15.90g La(NO 3 ) 3 ·6H 2 O, 6.00g citric acid was added to 200ml deionized water, mechanically stirred and heated to 60°C, and a solution A containing the four active components of cobalt, molybdenum, bismuth and lanthanum was prepared in one step.

[0041] Under vigorous stirring, the mass concentration of NaOH and Na 2 CO 3 The mixed solution and solution A were dropped into deionized water in a co-current manner to maintain the pH of the solution at 8.7±0.2. After full precipitation, the filter cake is transferred to a 1.0% mass concentration of oxalic acid solution, and the slurry is washed under vigorous stirring, suction filtration is repeated 3 times, the filter cake is dried at 80°C for 12 hours, and the dried catalyst is roasted , 20 ℃ after 1 h to 120 ℃, constant temperature at 120 ℃ for 1 h; then after 1 h to 300 ℃, consta...

Embodiment 3

[0044] Catalyst C-3:

[0045] Weigh 148gMg(NO 3 ) 2 , 156gAl(NO 3 ) 3 , 17.50g Co(NO 3 ) 2 ·6H 2 O, 8.85g (NH 4 ) 2 ·MoO 4 , 12.50gBi(NO 3 ) 3 ·5H 2 O, 10.6g La(NO 3 ) 3 ·6H 2 O, 6.00g citric acid was added to 200ml deionized water, mechanically stirred and heated to 70°C, and a solution A containing the four active components of cobalt, molybdenum, bismuth and lanthanum was prepared in one step.

[0046] Under vigorous stirring, the mass concentration of NaOH and Na 2 CO 3 The mixed solution and solution A are dropped into deionized water in a co-current manner, and the pH of the solution is maintained at 9.3±0.2. After full precipitation, the filter cake is transferred to the oxalic acid solution with a mass concentration of 3.0%. The filter cake is beaten and washed under vigorous stirring. The suction filter is repeated 3 times. The filter cake is dried at 80°C for 12 hours, and the dried catalyst is roasted. , 20 ℃ after 1 h to 120 ℃, constant temperature at 120 ℃ for 1 h; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com