Botanical filler constructed subsurface wetland constructing and running method

A subsurface wetland and plant matter technology is applied in the field of plant matter filler artificial subsurface wetland construction and operation, which can solve the problems of high construction cost and maintenance cost, reduced application prospects, lack of solutions, etc., and achieves poor denitrification effect. , reduce waste of resources and secondary pollution, and build simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

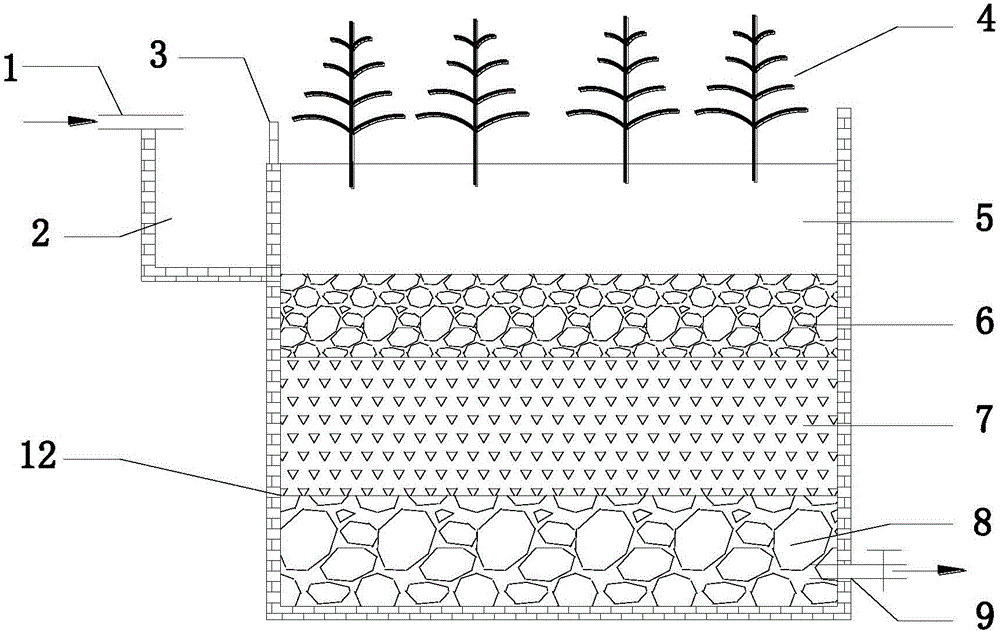

[0046] Embodiment 1: As introduced in the background technology, there are shortcomings in the prior art that artificial wetlands lack carbon sources and have high costs. In order to solve the above technical problems, this application proposes a plant material filled artificial subsurface flow wetland construction. The constructed wetland construction provided by this embodiment has a structure such as figure 1 and Figure 7 Shown:

[0047] The packing bed 12 of the main body of the wetland has an aspect ratio of 2:1 and a slope of 4%. The overflow weir 2 is built along the water flow direction, and the water distribution baffle 3 is arranged at the outlet of the overflow weir 2. The water distribution baffle 3 is evenly distributed. Arrange water holes 11 with a diameter of 20 mm, and fill the packed bed 12 with a height of 90 cm, and fill the gravel with a thickness of 20 cm and a particle size of 40-50 mm in order from bottom to top, so that it becomes the lower gravel la...

Embodiment 2

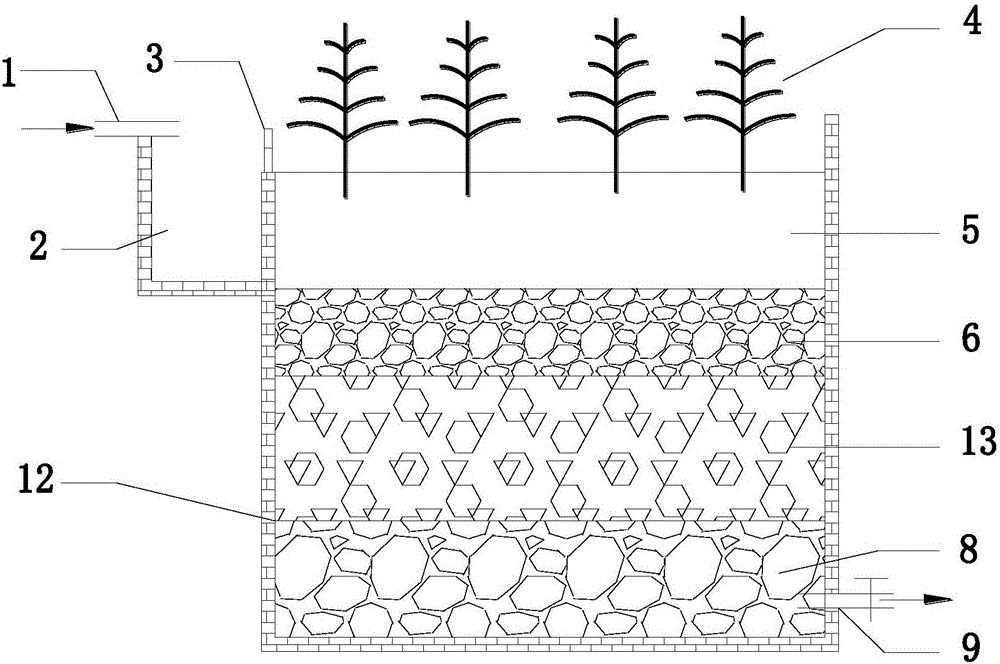

[0054] Embodiment 2: A kind of plant matter filler artificial subsurface flow wetland construction, such as figure 2 and Figure 7 As shown, the constructed wetland is a horizontal subsurface flow constructed wetland. The aspect ratio of the packing bed 12 of the main body of the wetland is 2:1, and the slope is 4%. The water baffle 3 and the water distribution baffle 3 are uniformly arranged with water holes 11 with an aperture of 20mm, and the packing bed 12 is 90cm high, and the gravel with a thickness of 20cm and a particle size of 60-70mm is filled in order from bottom to top, so that it become the lower gravel layer 8;

[0055] A certain amount of lotus seed shell and water chestnut skin mixture, its thickness is 30cm, makes it become lotus seed shell and water caltrop skin mixed filler layer 13 (i.e. plant material layer);

[0056] Gravel with a thickness of 15 cm and a particle size of about 20 mm, making it the upper gravel layer 6;

[0057] A certain amount of sa...

Embodiment 3

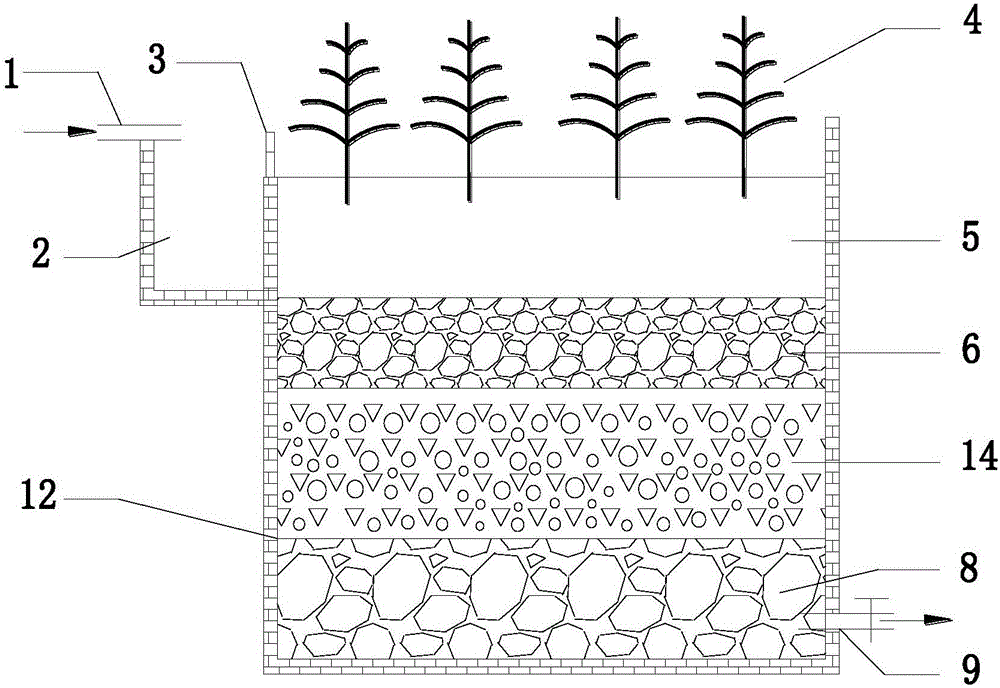

[0061] Embodiment 3: A kind of artificial subsurface flow wetland construction of plant matter filler, such as image 3 and Figure 7 As shown, the constructed wetland is a horizontal subsurface flow constructed wetland. The length-to-width ratio of the packing bed 12 in the main body of the wetland is 2:1, and the slope is 5%. The water baffle 3 and the water distribution baffle 3 are evenly arranged with water holes 11 with a diameter of 20mm, and the packing bed 12 is 90cm high, and the gravel with a thickness of 20cm and a particle size of 40-50mm is filled in order from bottom to top, so that it become the lower gravel layer 8;

[0062] A certain amount of lotus seed shell and Gorgon fruit mixture, the thickness of which is 30cm, makes it a lotus seed shell and Gorgon fruit mixed filler layer 14 (i.e. plant matter layer);

[0063] Gravel with a thickness of 15 cm and a particle size of about 20 mm, making it the upper gravel layer 6;

[0064] A certain amount of sand, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com