Treatment method for hydrogen sulfide in natural gas

A treatment method, hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of alcohol amine solvent loss, equipment corrosion, large area occupied by absorption towers and desorption towers, etc., to reduce the occupied area The effects of land area, saving land, and avoiding the loss of alcohol amine solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

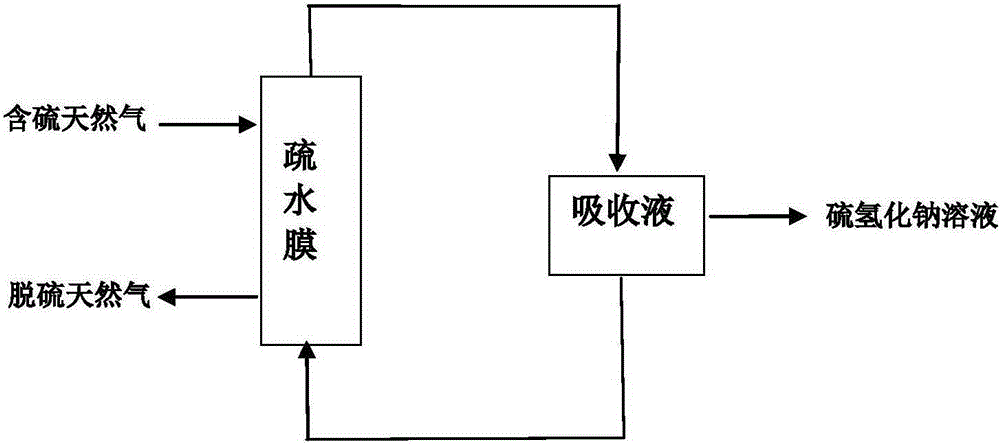

Image

Examples

Embodiment 1

[0041] The volume content of hydrogen sulfide in a certain natural gas is 2%.

[0042] The treatment steps are as follows: under the pressure of 0.1 MPa, the natural gas containing hydrogen sulfide is pressed into the shell side of the polypropylene hollow fiber hydrophobic membrane module with a pore size of 0.2 μm,

[0043] Sodium hydroxide solution with a mass concentration of 30% is used as the absorbing liquid, so that it circulates in reverse with the natural gas containing hydrogen sulfide in the tube side of the polypropylene hollow fiber hydrophobic membrane module, and the flow rate of the sodium hydroxide solution in the tube side is 0.5 m / s,

[0044] The hydrogen sulfide in the natural gas enters the sodium hydroxide absorption liquid through the membrane, and reacts to form sodium hydrogen sulfide, thereby realizing the removal of hydrogen sulfide in the natural gas.

[0045] The hydrogen sulfide content in the natural gas treated by the above steps is less than ...

Embodiment 2

[0047] The volume content of hydrogen sulfide in a certain natural gas is 5%.

[0048] The treatment steps are as follows: under the pressure of 0.2 MPa, the natural gas containing hydrogen sulfide is pressed into the shell side of the polypropylene hollow fiber hydrophobic membrane module with a pore size of 0.15 μm,

[0049] Sodium hydroxide solution with a mass concentration of 35% is used as the absorbing liquid, so that it circulates in reverse with the natural gas containing hydrogen sulfide in the tube side of the polypropylene hollow fiber hydrophobic membrane module, and the flow rate of the sodium hydroxide solution in the tube side is 0.7 m / s,

[0050] The hydrogen sulfide in the natural gas enters the sodium hydroxide absorption liquid through the membrane, and reacts to form sodium hydrogen sulfide, thereby realizing the removal of hydrogen sulfide in the natural gas.

[0051] The hydrogen sulfide content in the natural gas treated by the above steps is less than...

Embodiment 3

[0053] The volume content of hydrogen sulfide in a certain natural gas is 8%.

[0054]The treatment steps are as follows: under the pressure of 0.2 MPa, the natural gas containing hydrogen sulfide is pressed into the shell side of the polypropylene hollow fiber hydrophobic membrane module with a pore size of 0.15 μm,

[0055] Sodium hydroxide solution with a mass concentration of 40% is used as the absorption liquid, so that it flows in reverse circulation with natural gas containing hydrogen sulfide in the tube side of the polypropylene hollow fiber hydrophobic membrane module, and the flow rate of the sodium hydroxide solution in the tube side is 0.8 m / s,

[0056] The hydrogen sulfide in the natural gas enters the sodium hydroxide absorption liquid through the membrane, and reacts to form sodium hydrogen sulfide, thereby realizing the removal of hydrogen sulfide in the natural gas.

[0057] The hydrogen sulfide content in the natural gas treated by the above steps is less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com