Polybenzimidazole/polyvinylbenzyl chloride cross-linked high temperature proton exchange membrane with high oxidation resistance, and production method thereof

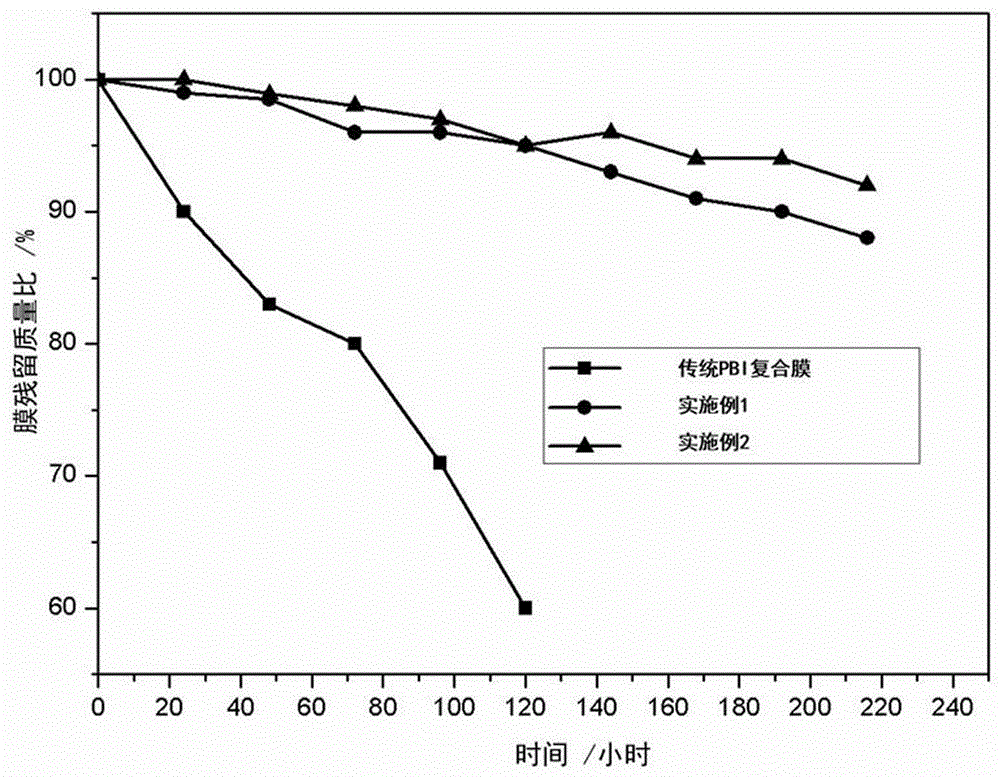

A technology of polyvinylbenzyl chloride and polybenzimidazole, which is applied in the field of polybenzimidazole/polyvinylbenzyl chloride cross-linked high-temperature proton exchange membrane and its preparation, can solve the problem of battery performance degradation and aggravation of PBI membrane. Degradation and other problems, to achieve the effect of high anti-oxidation performance, excellent dimensional stability, and good proton conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a polybenzimidazole / polyvinylbenzyl chloride cross-linked high-temperature proton exchange membrane with high oxidation resistance, comprising the following steps:

[0029] (1) Dissolve 2 g of polybenzimidazole in 20 mL of N-methylpyrrolidone, then add polyvinylbenzyl chloride in an amount of 50% of the mass of polybenzimidazole, stir until dissolved, and cast The solution was poured into a glass mold and dried at 80°C to obtain a polybenzimidazole / polyvinyl benzyl chloride cross-linked film;

[0030] (2) Dissolve 0.5 g of polybenzimidazole in 10 mL of N-methylpyrrolidone, add the free radical quencher cerium oxide into the solution, stir ultrasonically for 1 h, and prepare a slurry with free radical quenching ability ; Its addition amount of free radical quencher is 0.3% of polybenzimidazole quality;

[0031] (3) Spray the obtained slurry evenly on both sides of the polybenzimidazole / polyvinyl benzyl chloride crosslinked film, and the spray thic...

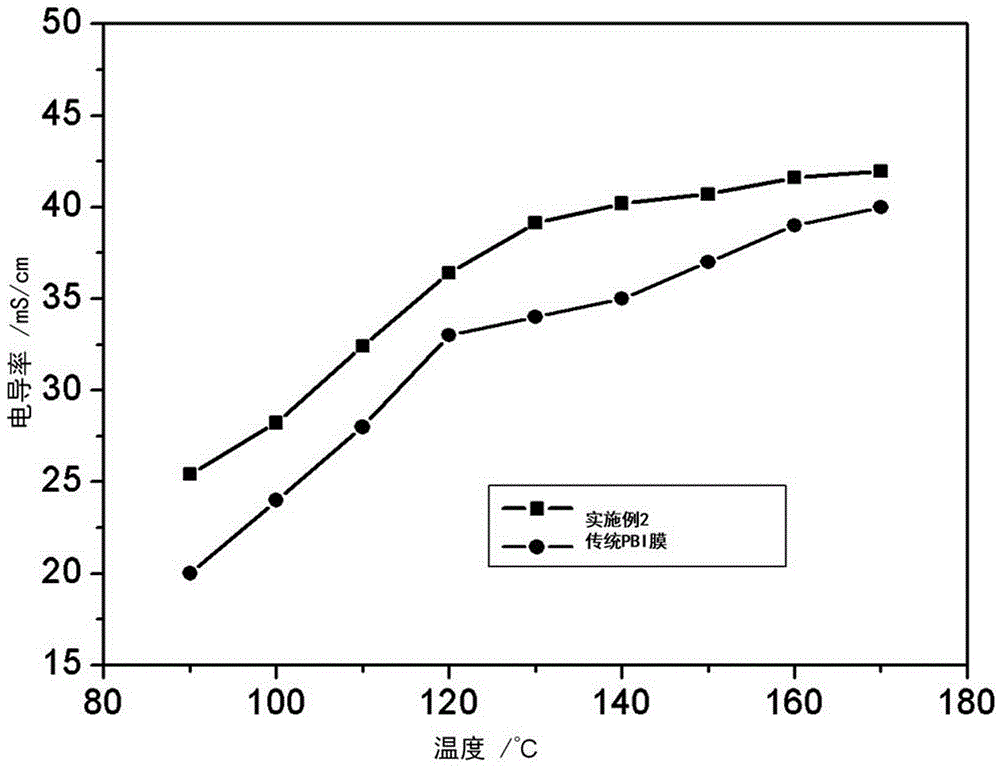

Embodiment 2

[0037] A method for preparing a polybenzimidazole polyvinylbenzyl chloride cross-linked high-temperature proton exchange membrane with high oxidation resistance, comprising the following steps:

[0038] (1) Dissolve 0.82 g polybenzimidazole in 10 mL N,N-dimethylacetamide, then add polyvinylbenzyl chloride, the amount added is 80% of the mass of polybenzimidazole, stir until dissolved Finally, pour the casting liquid into a glass mold and dry at 80°C to obtain a polybenzimidazole / polyvinyl benzyl chloride cross-linked film;

[0039] (2) Dissolve 0.2 g of polybenzimidazole in 8 mL of N,N-dimethylacetamide, add the free radical quencher cerium oxide into the solution, and stir it ultrasonically for 1 h to obtain a free radical quenching Ability slurry; the amount of free radical quencher is 0.9% of the polybenzimidazole mass;

[0040] (3) Spray the obtained slurry evenly on both sides of the polybenzimidazole / polyvinyl benzyl chloride cross-linked film, and the spray thickness i...

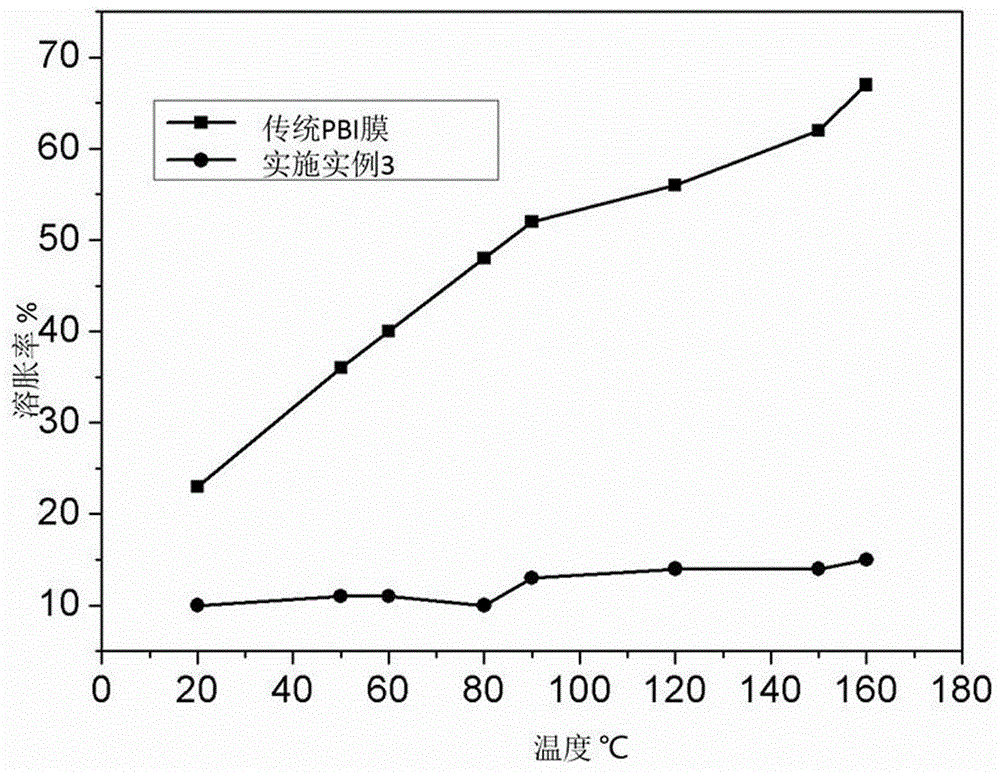

Embodiment 3

[0047] A method for preparing a polybenzimidazole polyvinylbenzyl chloride cross-linked high-temperature proton exchange membrane with high oxidation resistance, comprising the following steps:

[0048] (1) Dissolve 0.79 g of polybenzimidazole in 10 mL of N-methylpyrrolidone, then add polyvinylbenzyl chloride, the amount of which is 60% of the mass of polybenzimidazole, stir until dissolved, and pour the casting solution Pour into a glass mold and dry at 80°C to obtain a polybenzimidazole / polyvinyl benzyl chloride cross-linked film;

[0049] (2) Dissolve 0.2 g of polybenzimidazole in 8 mL of N-methylpyrrolidone, add the free radical quencher cerium oxide into the solution, stir ultrasonically for 1 h, and prepare a slurry with free radical quenching ability; Its add-on of base quencher is 0.4% of polybenzimidazole quality;

[0050] (3) Spray the obtained slurry evenly on both sides of the polybenzimidazole / polyvinyl benzyl chloride crosslinked film, and the spray thickness is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com