Fermented jerusalem artichoke straw for soilless culture, and composite medium of fermentative jerusalem artichoke straw

A technology of Jerusalem artichoke straw and soilless culture, applied in soilless culture, planting substrate, cultivation and other directions, can solve the problem of less research on comprehensive utilization of straw, and achieve the effects of improving disease resistance, increasing yield, and improving resource utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

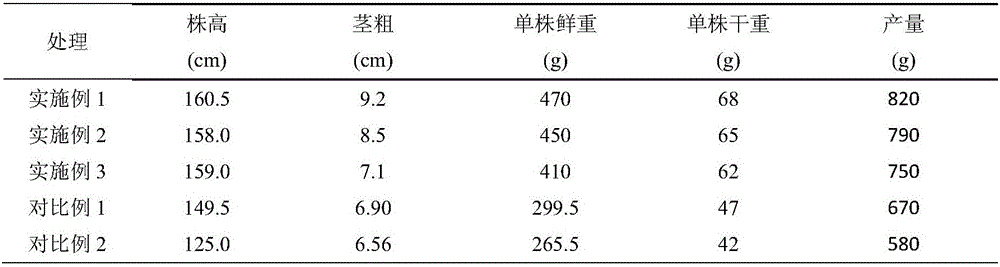

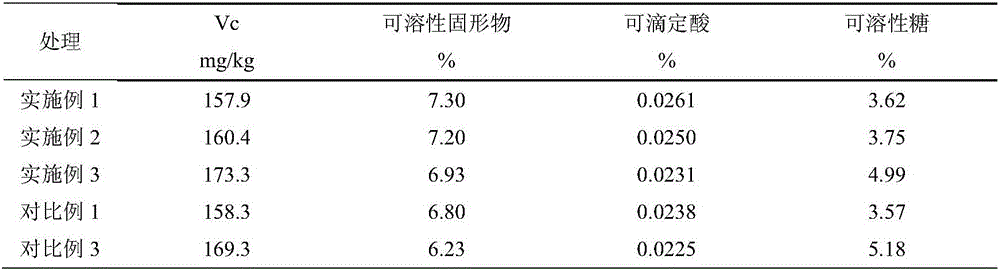

Examples

Embodiment 1

[0028] This embodiment relates to a preparation method of fermented Jerusalem artichoke stalks, comprising the following steps:

[0029] 1) Crush the air-dried Jerusalem artichoke stalks to 3-6 cm with a feeder for livestock, and stack them layer by layer according to the thickness of 15 cm. For each layer of straw, evenly pour the conditioning solution mixed with the starter to adjust the Jerusalem artichoke stalks. The water content of the straw heap is 50%, the C / N is 25:1, the total height to the said Jerusalem artichoke straw heap is 1.0m, and the surface is covered with a plastic film to obtain a heap of Jerusalem artichoke straw to be fermented;

[0030]2) Stack and ferment for 45 days. During the fermentation period, the water content is kept at 50% by replenishing water, and the pile is turned 2 to 3 times depending on the temperature and humidity.

[0031] The starter is an organic waste fermentation koji, and its addition amount is 0.4% of the total mass of the drie...

Embodiment 2

[0035] This embodiment relates to a preparation method of fermented Jerusalem artichoke stalks, comprising the following steps:

[0036] 1) Pulverize the Jerusalem artichoke straw to 3-6 cm with a feeder for livestock, and stack it layer by layer according to the thickness of 20 cm. For each layer of straw, evenly pour the conditioning solution mixed with the starter to adjust the density of the Jerusalem artichoke straw pile. The water content is 60%, the C / N is 35:1, the total height to the pile of Jerusalem artichoke straw is 1.2m, and the surface is covered with a plastic film to obtain a pile of Jerusalem artichoke straw to be fermented;

[0037] 2) Stack and ferment for 50 days. During the fermentation period, the moisture content is kept at 60% by replenishing water, and the pile is turned 2 to 3 times depending on the temperature and humidity.

[0038] The starter is an organic waste fermentation koji, and its addition amount is 0.5% of the total mass of the dried arti...

Embodiment 3

[0042] This embodiment relates to a preparation method of fermented Jerusalem artichoke stalks, comprising the following steps:

[0043] 1) Pulverize the Jerusalem artichoke straw to 3-6 cm with a feeder for livestock, and stack it layer by layer according to the thickness of 20 cm. For each layer of straw, evenly pour the conditioning solution mixed with the starter to adjust the density of the Jerusalem artichoke straw pile. The water content is 55%, the C / N is 30:1, the total height to the pile of Jerusalem artichoke straw is 1.0-1.2m, and the surface is covered with a plastic film to obtain a pile of Jerusalem artichoke straw to be fermented;

[0044] 2) Stack and ferment for 50 days. During the fermentation period, the moisture content is kept at 55% by replenishing water, and the pile is turned 2 to 3 times depending on the temperature and humidity.

[0045] The starter is an organic waste fermentation koji, and its addition amount is 0.5% of the total mass of the dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com