CBD production method of Mg-doped ZnO nanorods

A technology of nanorods and nanomaterials, applied in the direction of nanotechnology, zinc oxide/zinc hydroxide, etc., can solve the problems of high cost, expensive equipment, complicated process, etc., and achieve the effect of low cost and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

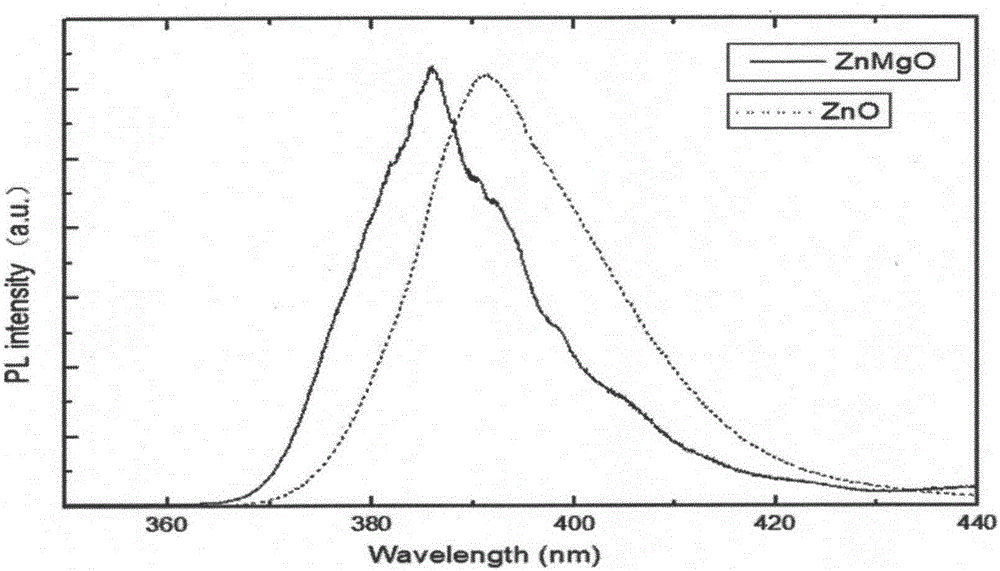

Image

Examples

Embodiment Construction

[0013] In order to make the present invention more comprehensible, preferred embodiments are described in detail as follows.

[0014] In the CBD preparation method of Mg-doped ZnO nanorods provided by the present invention, the growth of zinc oxide one-dimensional micro-nano materials is prepared by chemical bath deposition method. Experiments have proved that this method can be prepared by controlling appropriate growth conditions. Undoped and doped ZnO microrod materials are presented.

[0015] A CBD preparation method of Mg-doped ZnO nanorods provided by the present invention specifically includes the following steps:

[0016] Mg 2+ with Zn 2+ Zinc acetate and magnesium acetate with a molar ratio of 1:10 were dissolved in 100 ml of deionized water to prepare a zinc acetate solution. Among them, Mg 2+ The concentration is 0.003mol / l, Zn 2+ The concentration is 0.03mol / l. Another 0.75 mol of hexamethylenetetramine was prepared and loaded into a basic burette, and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com