Composite high temperature piezoelectric ceramic material and preparation method thereof

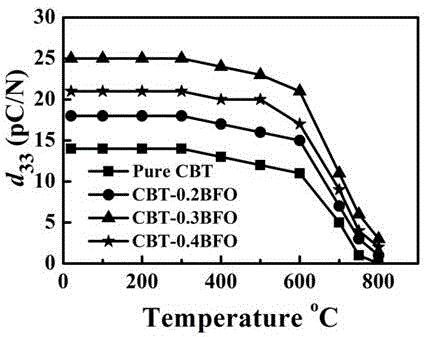

A ceramic material and high-temperature piezoelectric technology, applied in the field of composite high-temperature piezoelectric ceramic materials and their preparation, can solve the problems of bismuth ion volatilization, low-voltage electrical coefficient, low resistivity, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

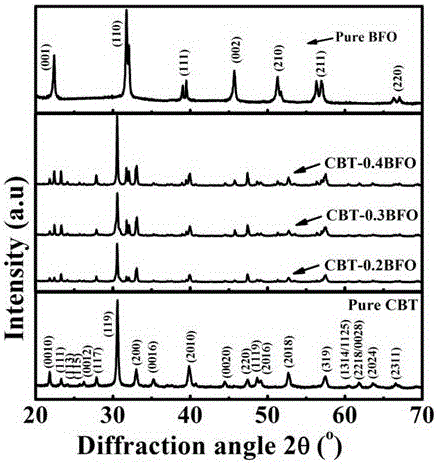

[0038] In this embodiment, analytically pure Bi 2 o 3 , Fe 2 o 3 Powder preparation of BiFeO 3 (Pure BFO for short) ceramics.

[0039] The preparation steps are: 1. the analytically pure Bi 2 o 3 , Fe 2 o 3 The powder is weighed according to the molar ratio of 1:1, mixed into the ball mill jar, and analytically pure absolute ethanol (accounting for about two-thirds to three-quarters of the volume of the ball mill jar) is added into the ball mill jar, and put into the ball mill Ball mill at 300 rpm for 8 hours.

[0040] 2. After the ball milling, pour the absolute ethanol containing the powder into a glass dish, and put it in a 140-degree oven for drying. After the powder is dried, use a mortar to grind it, then pour it into a corundum boat, and put it Put it into the muffle furnace for pre-burning, the pre-burning temperature is 850 degrees, and the pre-burning time is 2 hours.

[0041] 3. Add 0.5wt% polyvinyl alcohol of the total weight of the powder to the powder i...

Embodiment 2

[0047] In this embodiment, the analysis of pure CaCO 3 、 Bi 2 o 3 、TiO 2 Powder preparation of CaBi 4 Ti 4 o 15 (Pure CBT for short) ceramics.

[0048] The preparation steps are: 1. the analytically pure CaCO 3 、 Bi 2 o 3 、TiO 2 The powder is weighed according to the molar ratio of 1:2:4, mixed into the ball mill jar, and analytically pure anhydrous ethanol (accounting for about two-thirds to three-quarters of the volume of the ball mill jar) is added into the ball mill jar, and put Go into ball mill and ball mill with the rotating speed of 300 rpm for 8 hours.

[0049] 2. After the ball milling, pour the absolute ethanol containing the powder into a glass dish, and put it in a 140-degree oven for drying. After the powder is dried, use a mortar to grind it, then pour it into a corundum boat, and put it Enter the muffle furnace for pre-burning, the pre-burning temperature is 800 degrees, and the pre-burning time is 2 hours.

[0050] 3. Add 0.5wt% polyvinyl alcohol o...

Embodiment 3

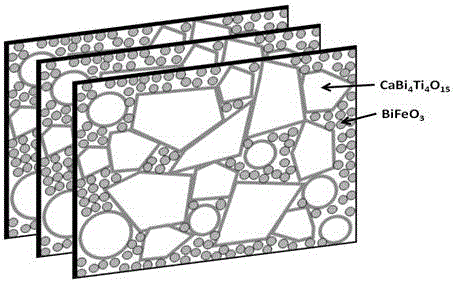

[0060] In this example, the BiFeO of Example 1 and Example 2 3 、CaBi 4 Ti 4 o 15 Powder preparation of CaBi 4 Ti 4 o 15 -0.2BiFeO 3 (referred to as CBT-0.2BFO) ceramics.

[0061] The preparation steps are: 1. the BiFeO obtained in Step 2 in Example 1 and Step 2 in Example 2 3 Powder and CaBi 4 Ti 4 o 15 The powder is weighed according to the molar ratio of 1:5, mixed into the ball mill jar, and analytically pure anhydrous ethanol (accounting for about two-thirds to three-quarters of the volume of the ball mill jar) is added into the ball mill jar, and put into Ball milled for 8 hours at a speed of 300 rpm in a ball mill.

[0062] 2. After the ball milling, pour the absolute ethanol containing the powder into a glass dish, and put it in a 140-degree oven to dry. After the powder is dried, add 0.5wt% of the total weight of the powder to the powder Polyvinyl alcohol is used as a binder, and after grinding again, it is pressed into a ceramic disc with a diameter of 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com