A kind of preparation method of flame-retardant polymethacrylimide foam and its parts

A polymethacrylimide and flame retardant technology, which is applied in the field of preparation of flame retardant high-performance polymethacrylimide materials and their parts, can solve the problem that the thickness of the flame retardant layer is small and cannot meet the requirements. , low peel strength of parts, etc., to achieve the effect of good flame retardant effect, high peel strength and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

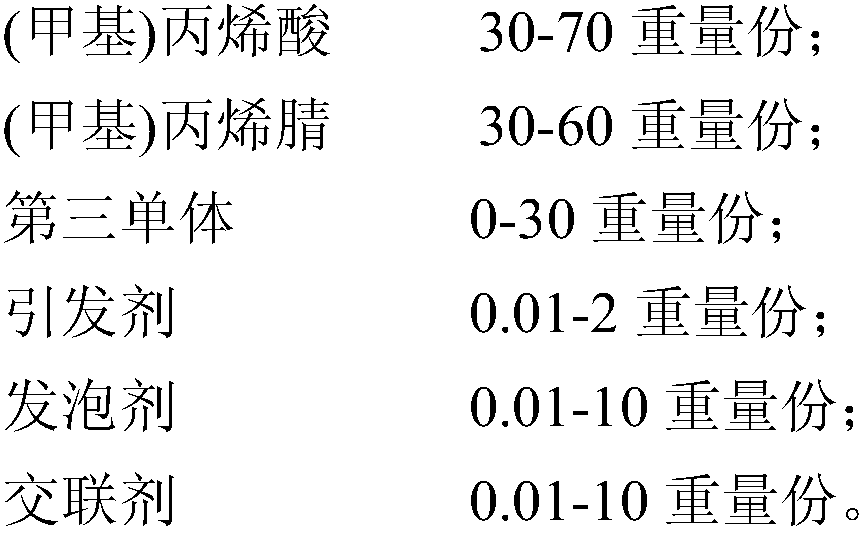

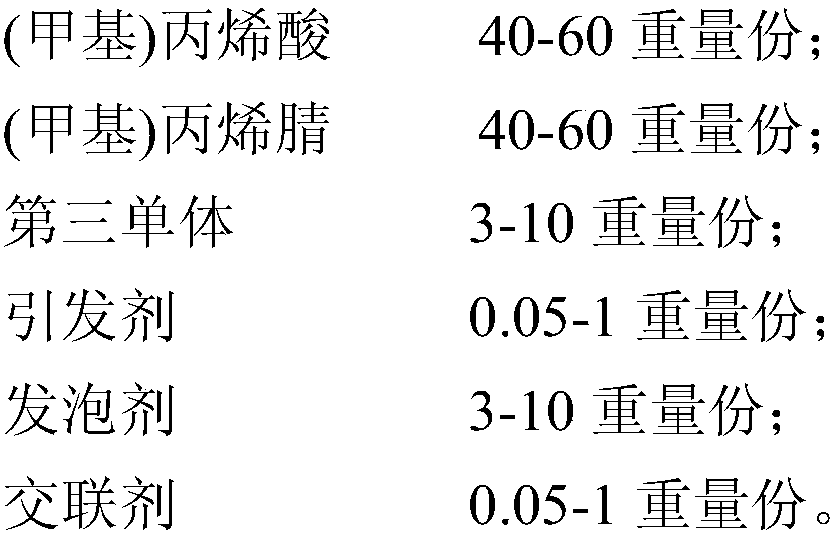

[0049] Preparation of pre-polymerized board: 44 parts by weight of methacrylic acid, 43 parts by weight of methacrylonitrile, 5 parts by weight of acrylamide monomer, 0.5 parts by weight of initiator, 5 parts by weight of foaming agent, and 0.1 part by weight of crosslinking agent as raw materials And mixed and stirred to obtain a uniform mixed liquid, then pre-polymerized in a closed mold at 42°C for 55h to obtain a transparent pre-polymerized block body, and then post-polymerized at 80°C for 70h.

[0050] Foaming: Then place the prepolymerized board in dimethyl propyl phosphonate and heat it to 140°C for 2 hours, heat it to 180°C for 2 hours, and cool it down to room temperature to get a flame retardant layer with a thickness of 10.5mm and a density of 155kg / m 3 flame retardant foam.

[0051] After the foam is peeled, the surface is rinsed and dried. The compressive strength of the obtained foam is 4.8MPa, and then it is combined with the basalt skin by hot pressing to make...

Embodiment 2

[0053] Preparation of pre-polymerized board: 44 parts by weight of methacrylic acid, 43 parts by weight of methacrylonitrile, 5 parts by weight of acrylamide monomer, 0.5 parts by weight of initiator, 5 parts by weight of foaming agent, and 0.1 part by weight of crosslinking agent as raw materials And mixed and stirred to obtain a uniform mixed liquid, then pre-polymerized in a closed mold at 42°C for 55h to obtain a transparent pre-polymerized block body, and then post-polymerized at 80°C for 70h.

[0054] Foaming: Then place the prepolymerized board in triethyl phosphate and heat it to 150°C for 2 hours, heat it to 185°C for 2 hours, and cool it down to room temperature to get a flame retardant layer with a thickness of 12mm and a density of 150kg / m 3 flame retardant foam.

[0055] After the foam is peeled, the surface is rinsed and dried. The compressive strength of the obtained foam is 4.5MPa, and then it is combined with the basalt skin by hot pressing to make a product. ...

Embodiment 3

[0057] Preparation of pre-polymerized board: 44 parts by weight of methacrylic acid, 43 parts by weight of methacrylonitrile, 5 parts by weight of acrylamide monomer, 0.5 parts by weight of initiator, 5 parts by weight of foaming agent, and 0.1 part by weight of crosslinking agent as raw materials And mixed and stirred to obtain a uniform mixed liquid, then pre-polymerized in a closed mold at 42°C for 55h to obtain a transparent pre-polymerized block body, and then post-polymerized at 80°C for 70h.

[0058] Foaming: Then place the prepolymerized board in triethyl phosphate and heat it to 160°C for 2.5 hours, heat it to 190°C for 2 hours, and cool it down to room temperature to get a flame retardant layer with a thickness of 12mm and a density of 145kg / m 3 flame retardant foam.

[0059] After the foam is peeled, the surface is rinsed and dried. The compressive strength of the obtained foam is 4.2MPa, and then it is combined with the basalt skin by hot pressing to make a produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com