AlSi9 aluminum alloy material, and preparation method and application thereof

A technology of aluminum alloy materials and raw materials, which is applied in the field of AlSi9 aluminum alloy materials and its preparation and application, can solve the problems of low yield strength of shock absorbing parts, high part defective rate, expensive parts, etc., and achieve low production cost and no burrs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation method of AlSi9 aluminum alloy material:

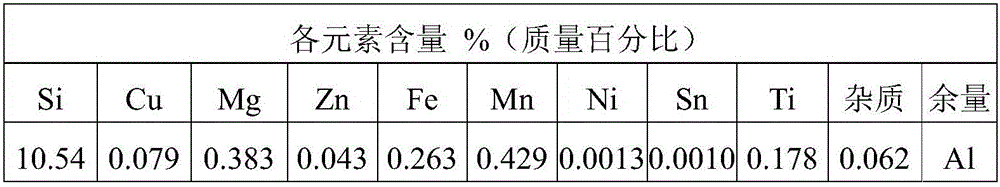

[0037] (1) The crystalline silicon, copper, iron, and aluminum are first screened and cleaned, and the target ingredients are mixed according to the target composition in Table 1, and then manganese is added to obtain a mixture;

[0038] Among them, the content of silicon in crystalline silicon is ≥98wt%. In copper, the content of copper is ≥95wt%; in iron, the content of iron is ≥95wt%. Aluminum includes pure aluminum, raw aluminum and cooked aluminum. In pure aluminum, the content of iron is ≤0.1wt%; in cooked aluminum, the content of iron is ≤1.0wt% and the content of lead is ≤0.2wt%; in raw aluminum, The content of iron element is ≤1.5wt%, and the content of lead element is ≤0.2wt%.

[0039] Among them, the purpose of screening is to remove the fine ash in the raw materials; the purpose of cleaning is to clean the raw materials; the purpose of sieving is to make the zinc content ≤0.1wt%;

[0040] In the manganese agen...

Embodiment 2

[0050] Preparation method of AlSi9 aluminum alloy material:

[0051] (1) The crystalline silicon, copper, iron, and aluminum are first screened and cleaned, and the target ingredients in Table 2 are mixed, and then manganese is added to obtain a mixture;

[0052] Among them, the content of silicon in crystalline silicon is ≥98wt%. In copper, the content of copper is ≥95wt%; in iron, the content of iron is ≥95wt%. Aluminum includes pure aluminum, raw aluminum and cooked aluminum. In pure aluminum, the content of iron is ≤0.1wt%; in cooked aluminum, the content of iron is ≤1.0wt% and the content of lead is ≤0.2wt%; in raw aluminum, The content of iron element is ≤1.5wt%, and the content of lead element is ≤0.2wt%.

[0053] Among them, the purpose of screening is to remove the fine ash in the raw materials; the purpose of cleaning is to clean the raw materials; the purpose of sieving is to make the zinc content ≤0.1wt%;

[0054] In the manganese agent, the manganese content is about 75...

Embodiment 3

[0064] In Example 3, the preparation method is the same as that in Example 1, except that the ingredients are prepared according to the target ingredients in Table 3.

[0065] The AlSi9 aluminum alloy material prepared in Example 3 was subjected to composition analysis, and the test results are shown in Table 3. Among them, the material analysis instrument is a German direct-reading spectrometer, brand Spectro.

[0066] table 3

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com