Ordinary-pressure direct-heating boiler integrating opening type heat exchanger and filled tower

A technology of packed towers and heat exchangers, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as unfavorable water intake distribution, energy loss, occupying packing space, etc., and achieve a wide range of water quality adaptation, The effect of reducing water loss and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the purpose, technical solution and features of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following content is used to illustrate the present invention, but not to limit the scope of the present invention.

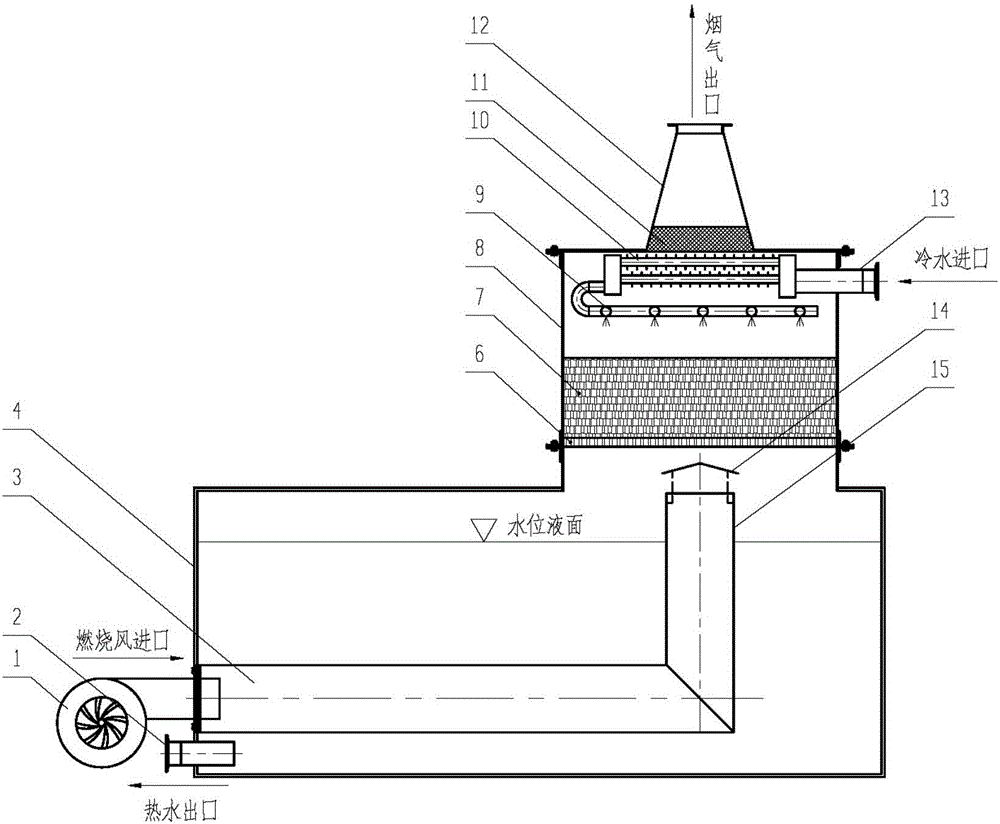

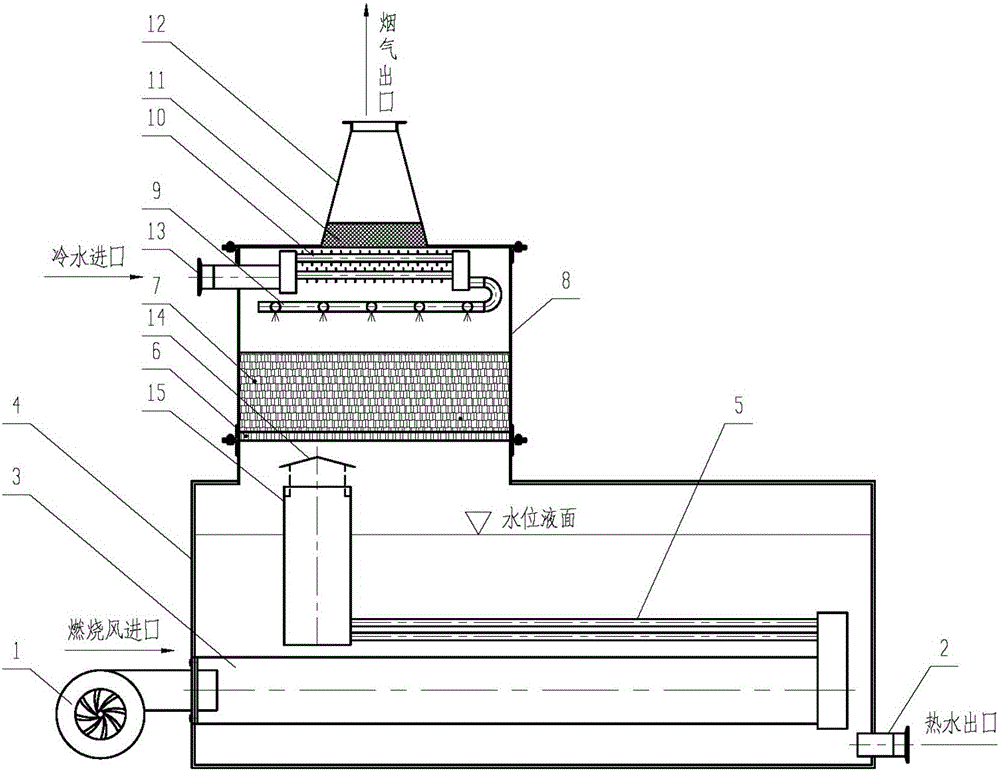

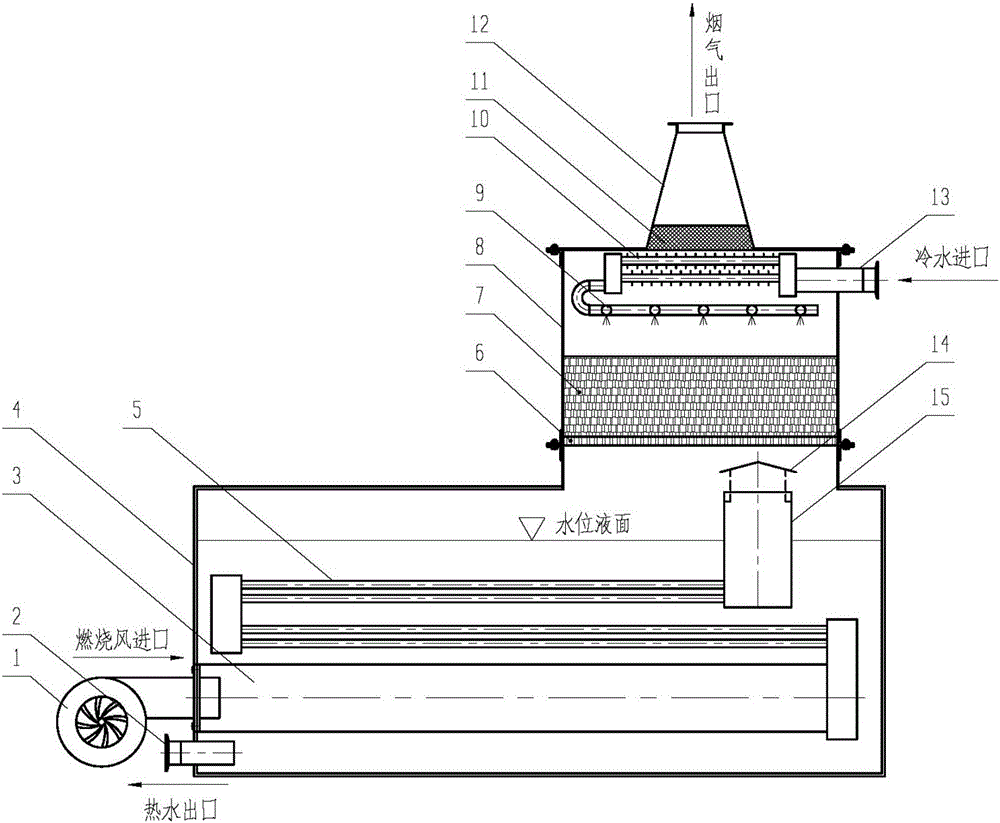

[0062] In the attached picture, figure 1 (one program), figure 2 (second program), image 3 (Three programs) respectively correspond to low-power, medium-power and high-power atmospheric pressure direct-heating boilers. The composition of the open type heat exchanger and packing tower combined atmospheric pressure direct heating boiler of the present invention is as follows: frequency conversion burner 1, outlet pipe 2, combustion cylinder 3, water tank 4, heat exchange tube bundle 5, packing grid 6, packing 7, Packing container 8, spray pipe group 9, condensing pipe group 10, wire mesh demister 11, chimney 12, water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com