Capacitance-type absolute-pressure micro-pressure gas pressure sensor based on SOI-MEMS (Silicon on Insulator-Micro-Electro-Mechanical System) technology

A pressure sensor and capacitive technology, which is applied in the field of capacitive absolute pressure and micro pressure air pressure sensor sensitive chip, can solve the problems of complex micro-nano processing procedures, expensive instruments and equipment, and high yield guarantee challenges, etc., to achieve vacuum Excellent long-term maintenance capability, guaranteed yield, and small parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

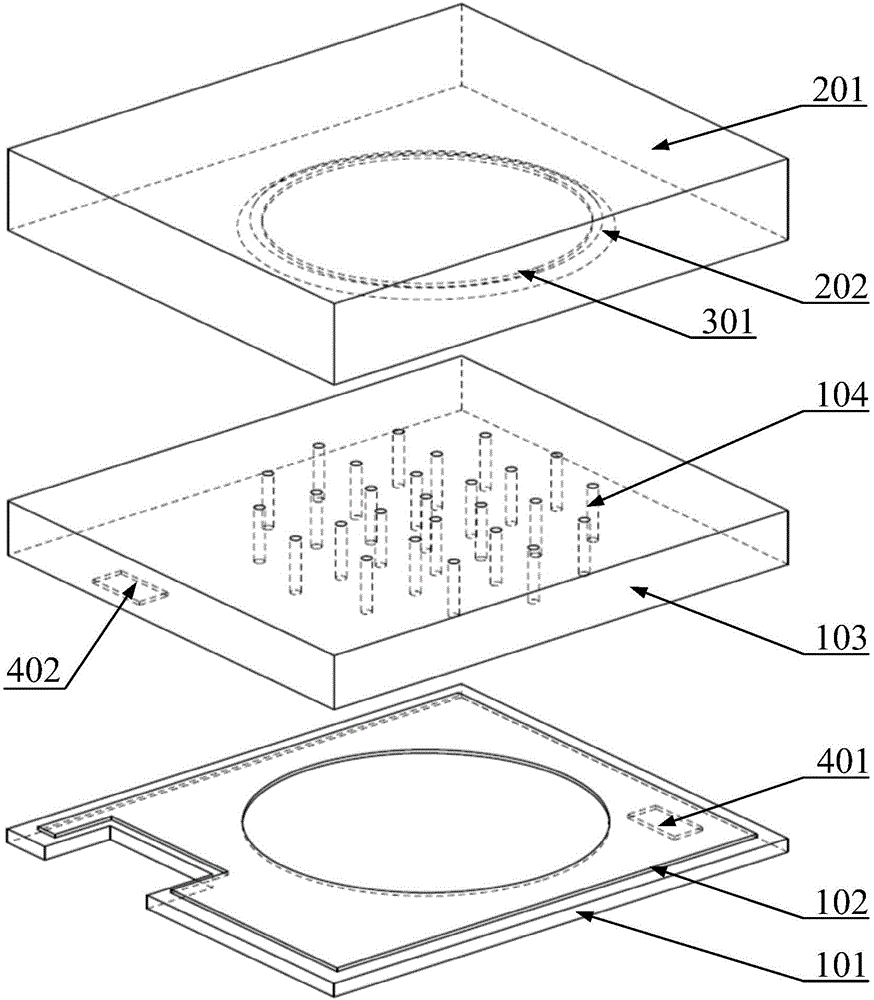

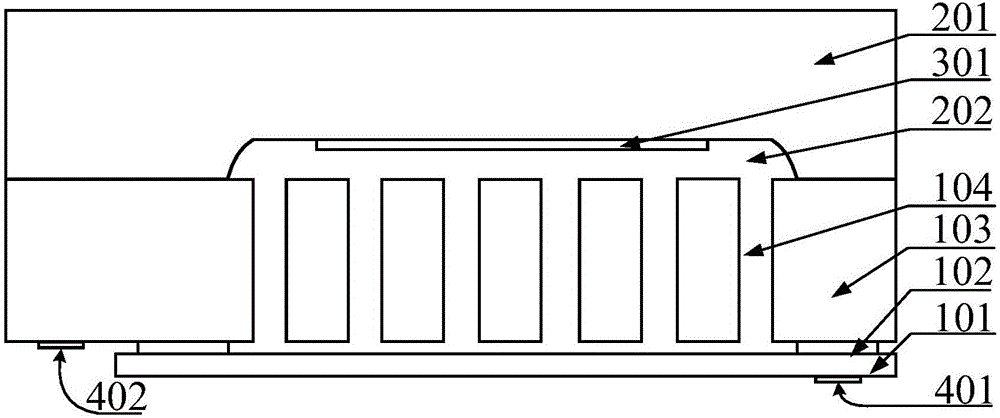

[0025] Such as figure 1 Shown is a schematic diagram of the structural anatomy of the sensor. It can be seen from the figure that the capacitive absolute pressure micro-pressure air pressure sensor based on SOI-MEMS technology includes an SOI wafer device layer 101, a silicon dioxide layer 102, an SOI wafer substrate layer 103 and a bond. Combined packaging cover glass 201; wherein, the SOI wafer device layer 101 is a square structure, and is horizontally located at the bottom; the silicon dioxide layer 102 is fixedly installed on the upper surface of the SOI wafer device layer 101; the SOI wafer substrate layer 103 is fixedly installed On the upper surface of the silicon dioxide layer 102; the bonding package cover glass 201 is fixedly installed on the upper surface of the SOI wafer substrate layer 103; the bonding package cover glass 201 is bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com