Cerenkov radiation device, preparation method and method for extracting radiation

A technology of radiation device and electron emission source, which is applied in the field of extraction of Cherenkov radiation, Cherenkov radiation device, and preparation, and can solve the problems to be improved and difficult to meet the requirements of practical applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

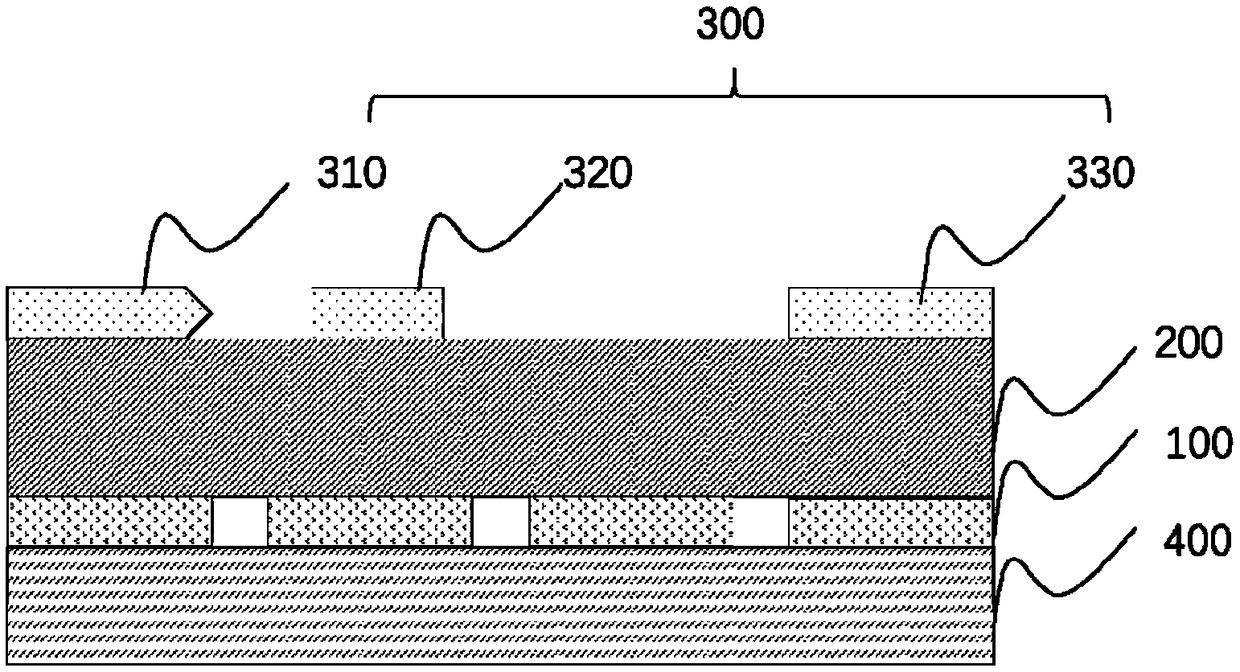

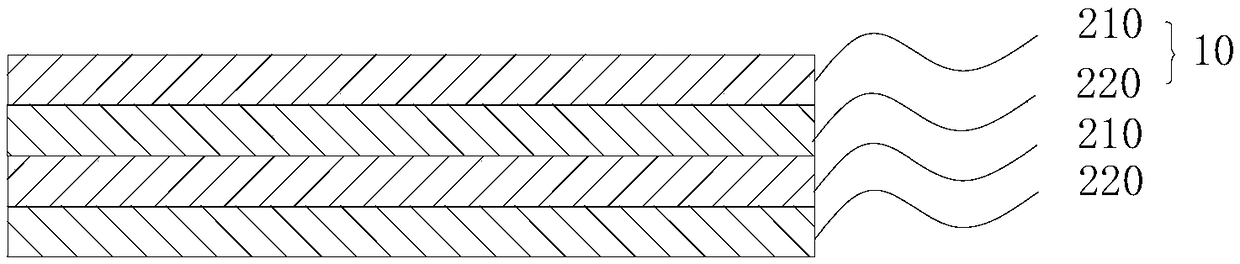

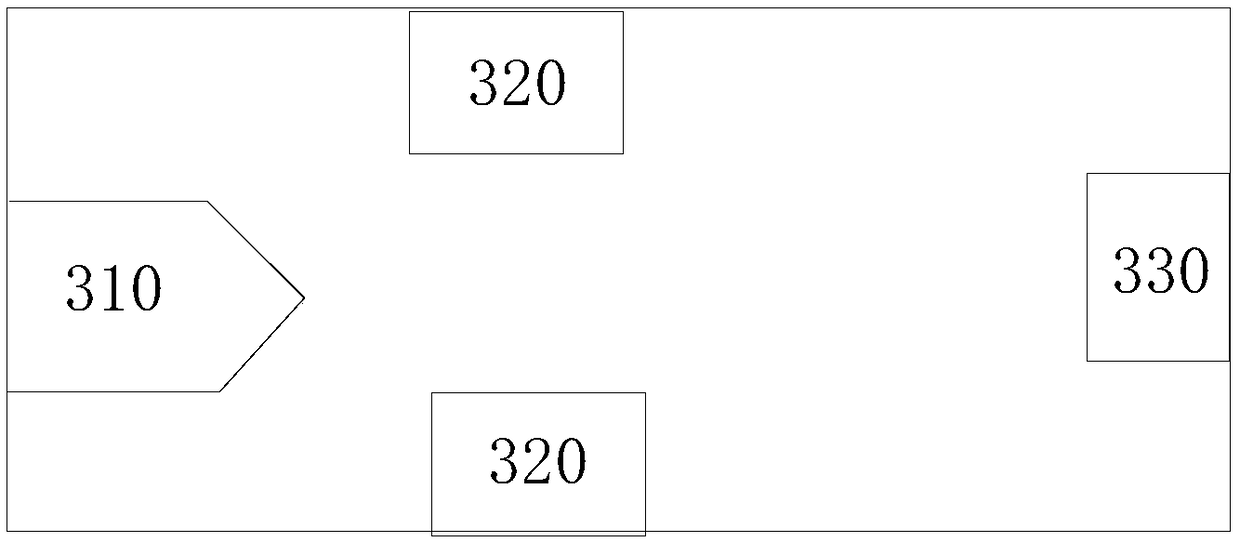

[0067] Au is used to form the metal periodic nano-slit structure, wherein the Au film thickness is 100nm, the slit period is 800nm, and the duty ratio is 0.12. The hyperbolic metamaterial structure adopts the dielectric-conductor alternating multilayer film form, in which the conductor is Au and the dielectric is SiO 2 . The production process is as follows: first grow a layer of SiO on the already fabricated metal periodic nano-slit structure 2 As an isolation layer, this SiO 2 The layer thickness is about 50 nm. Next, by magnetron sputtering method on SiO 2 A layer of Au film was grown on the surface of the layer with a thickness of 10nm. Repeat this process to alternately grow 10nm SiO 2 and 10nm Au, a total of 20 layers of films were produced for ten cycles. The metal used is Mo to prepare the electron emission source, and a layer of SiO is first grown 2 As an isolation layer, the thickness is about 40nm, as an insulating isolation layer, and then make the electrode...

Embodiment 2

[0069] Al is used to form a metal periodic nano-slit structure, wherein the Al film thickness is 100nm, the slit period is 300nm, and the duty ratio is 0.12. The hyperbolic metamaterial structure adopts the dielectric-conductor alternating multilayer film form, in which the conductor is Al and the dielectric is SiO 2 . The production process is as follows: first grow a layer of SiO on the already fabricated metal periodic nano-slit structure 2 As an isolation layer, this SiO 2 The layer thickness is about 10 nm. Next, by magnetron sputtering method on SiO 2 A layer of Al film was grown on the surface of the layer with a thickness of 10nm, and then a layer of SiO was sputtered 2 film with a thickness of 10 nm. Repeat this process to alternately grow 10nm Al and 10nm SiO 2 , making a total of twenty layers of film ten cycles. The metal used is Mo to prepare the electron emission source, and a layer of SiO is first grown 2 As an isolation layer, the thickness is about 30n...

Embodiment 3

[0071] Au is used to form the metal periodic nano-slit structure, in which the Au film thickness is 100 nm, the slit period is 300 μm, and the duty ratio is 0.12. The hyperbolic metamaterial structure adopts the form of dielectric-conductor alternating multilayer film, in which the conductor is graphene and the dielectric is Si. The production process is as follows: first grow a layer of SiO on the already fabricated metal periodic nano-slit structure 2 As an isolation layer, this SiO 2 The layer thickness is about 50 nm. Next, transfer about 0.3nm graphene to SiO by graphene transfer technology 2 Layer surface, and then use sputtering method to prepare a layer of Si film with a thickness of 15nm. Repeat this process, alternately transfer 0.3nm graphene and grow 15nm Si, and make a total of 20 layers of films for ten cycles. The metal used is Mo to prepare the electron emission source, and a layer of SiO is first grown 2 As an isolation layer, the thickness is about 40nm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com