Positive electrode active material, method for producing same, and lithium secondary battery

A positive electrode active material, a positive electrode technology, applied in the field of positive electrode active material, its manufacture and lithium secondary battery, can solve the problems of unsatisfactory results, deterioration of battery performance, limited price competitiveness, etc., to improve electrochemical performance and long-term reliability, and the effect of suppressing oxidative decomposition reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

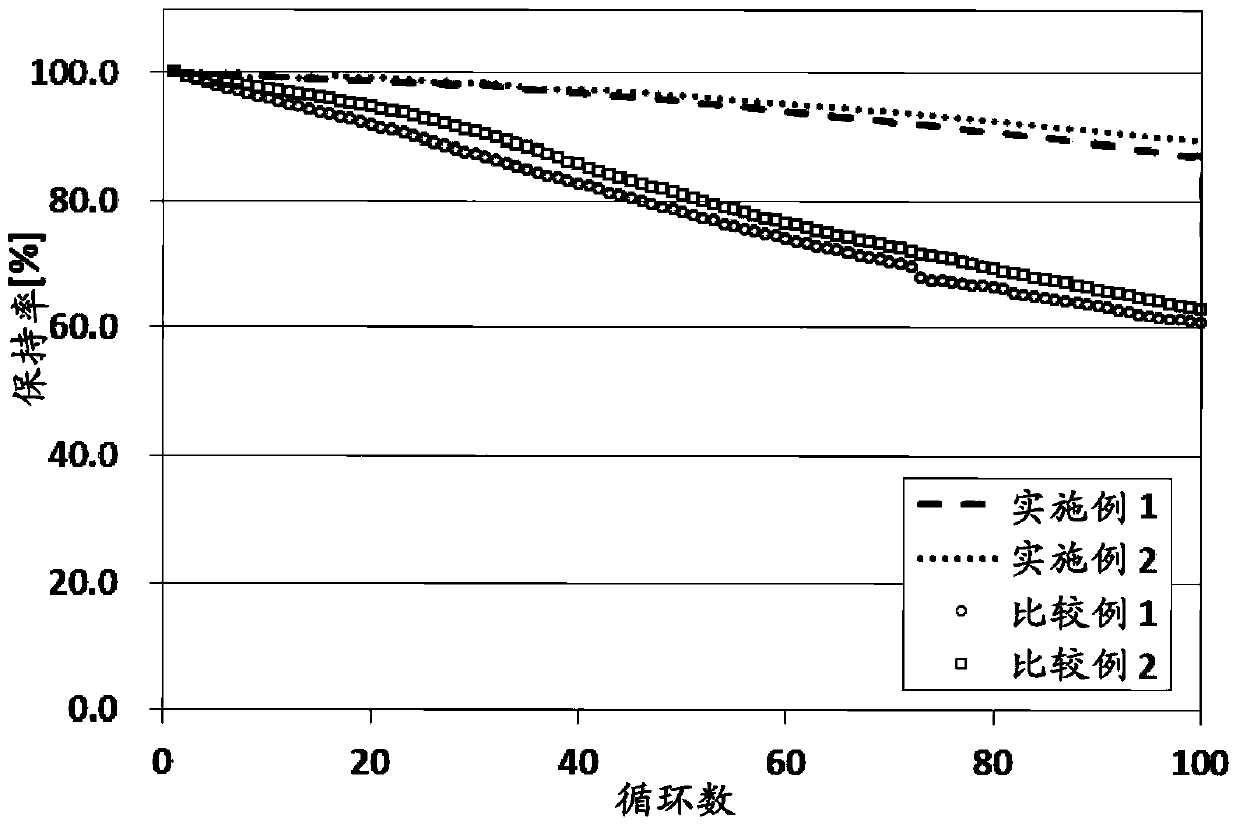

Embodiment 1

[0088] 1-1. Manufacture of cathode active material

[0089] In order to produce NCM-based positive electrode active materials, first, Ni is produced by co-precipitation reaction 0.8 co 0.1 mn 0.1 (OH) 2 After the precursor, LiOH was added as a lithium compound and heat-treated at 780 °C for 12 h to produce Li 1.01 Ni 0.8 co 0.1 mn 0.1 o 2 Represented positive active material.

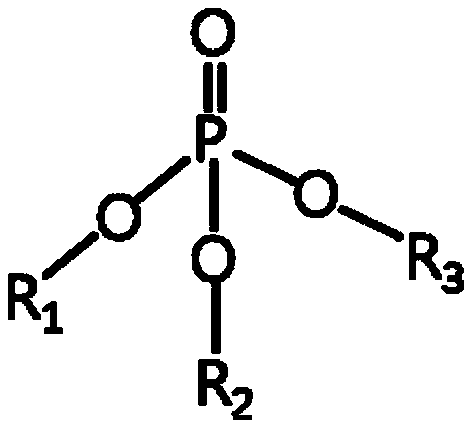

[0090] After applying 10 parts by weight of tributyl phosphate to 100 parts by weight of the manufactured positive electrode active material, heat treatment was performed at 300° C. for 3 hours, thereby manufacturing the positive electrode active material of Example 1.

[0091] 1-2. Cathode manufacturing

[0092] 95 parts by weight of the positive electrode active material manufactured in Example 1-1, 2.5 parts by weight of the PvdF binder, and 2.5 parts by weight of carbon black as a conductive agent were dispersed in the NMP solution to prepare the slurry, which was coated on the Al colle...

Embodiment 2

[0096] The positive electrode active material of Example 2 was produced by implementing the same method as in Example 1 above except that triphenyl phosphate was used instead of tributyl phosphate.

[0097] Using the above-mentioned positive electrode active material, a positive electrode and a lithium secondary battery were respectively manufactured according to the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com