Graphene oxide-modified organic solvent-resistant nanofiltration membrane, preparation method and application

A technology resistant to organic solvents and organic solvents, applied in the field of nanofiltration membranes, can solve problems such as lack of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

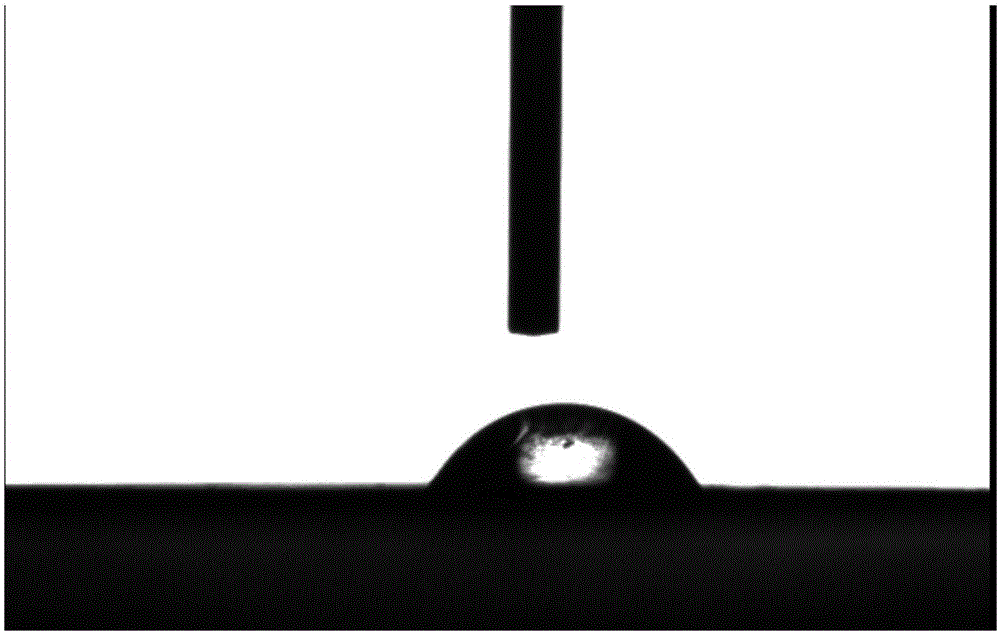

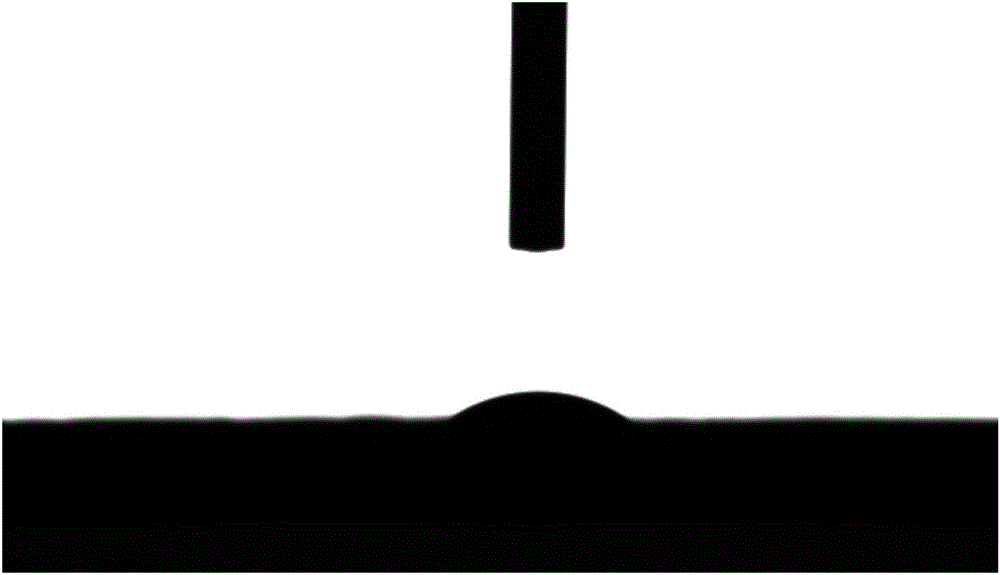

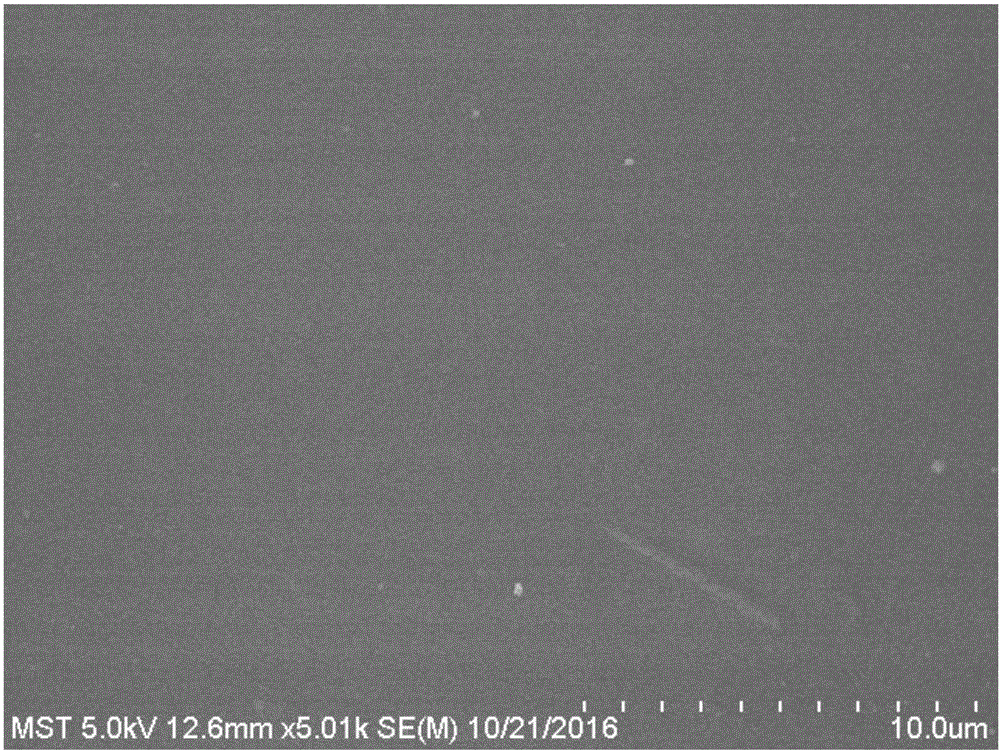

[0037]The preparation method of the above-mentioned composite nanofiltration membrane is mainly to dissolve the polyimide and the additive polyethylene glycol in an organic solvent, and then coat it on the support layer by phase separation to obtain a wet membrane; , by placing it in a cross-linking agent solution, carrying out a cross-linking reaction, taking it out and washing it to obtain a modified nanofiltration membrane, which can realize the surface cross-linking modification on the polyimide layer, and can better improve the bonding strength of the graphene oxide layer .

[0038] In the above steps, the weight ratio of polyimide, polyethylene glycol and organic solvent is preferably 20:10-22:30-75, preferably 20:16:64. Wherein polyethylene glycol is preferably polyethylene glycol 200~6000, more preferably polyethylene glycol 200~600, more preferably polyethylene glycol 400; Described organic solvent is preferably selected from N-methylpyrrolidone, N-N, 2-methylformami...

Embodiment 1

[0043] (1) Dissolve polyimide P84 and polyethylene glycol (400) in N-methylpyrrolidone at a mass ratio of 20:12:50, stir mechanically at room temperature for 48 hours, wait until it is completely dissolved, and statically Set for 12h for degassing. Use an automatic film scraping machine to scrape and coat the casting solution on a clean glass plate, control the thickness of the scraper to 100 μm, control the volatilization time for 5 seconds, immerse in a deionized water coagulation bath, phase separation occurs and solidify to form a film, take it out after soaking for 3 minutes Store in deionized water.

[0044] (2) Prepare an isopropanol solution containing 10wt% 1,6-hexamethylenediamine, soak the above-mentioned basement film in the solution, and control for 24 hours to carry out the cross-linking reaction. When the reaction is complete, take it out and wash it three times with deionized water to remove residual organic matter, soak in deionized water for 24 hours, and ch...

Embodiment 2

[0049] (1) Dissolve polyimide P84 and polyethylene glycol (600) in N-methylpyrrolidone at a mass ratio of 20:13:55, mechanically stir at room temperature for 30 hours, wait until it is completely dissolved, and statically Set for 10h for degassing. Use an automatic film scraping machine to scrape and coat the casting solution on a clean glass plate, control the thickness of the scraper to 80 μm, control the volatilization time for 5 seconds, immerse in a deionized water coagulation bath, phase separation occurs and solidify to form a film, take it out after soaking for 3 minutes Store in deionized water.

[0050] (2) Prepare an ethanol solution containing 12wt% ethylenediamine, soak the basement film in the solution, and control for 15 hours to carry out cross-linking reaction. When the reaction is complete, take it out and wash it three times with deionized water to remove residual organic matter, soak in deionized water for 36 hours, and change the water every 12 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com