Hydrodenitrogenation catalyst for LCO (light cycle oil) and preparation method of hydrodenitrogenation catalyst

A light cycle oil, hydrodenitrogenation technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of high operating costs, large environmental pollution, removal of light cycle oil nitrogen and other problems, to achieve the effect of simple activation operation, reducing pollution and high denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

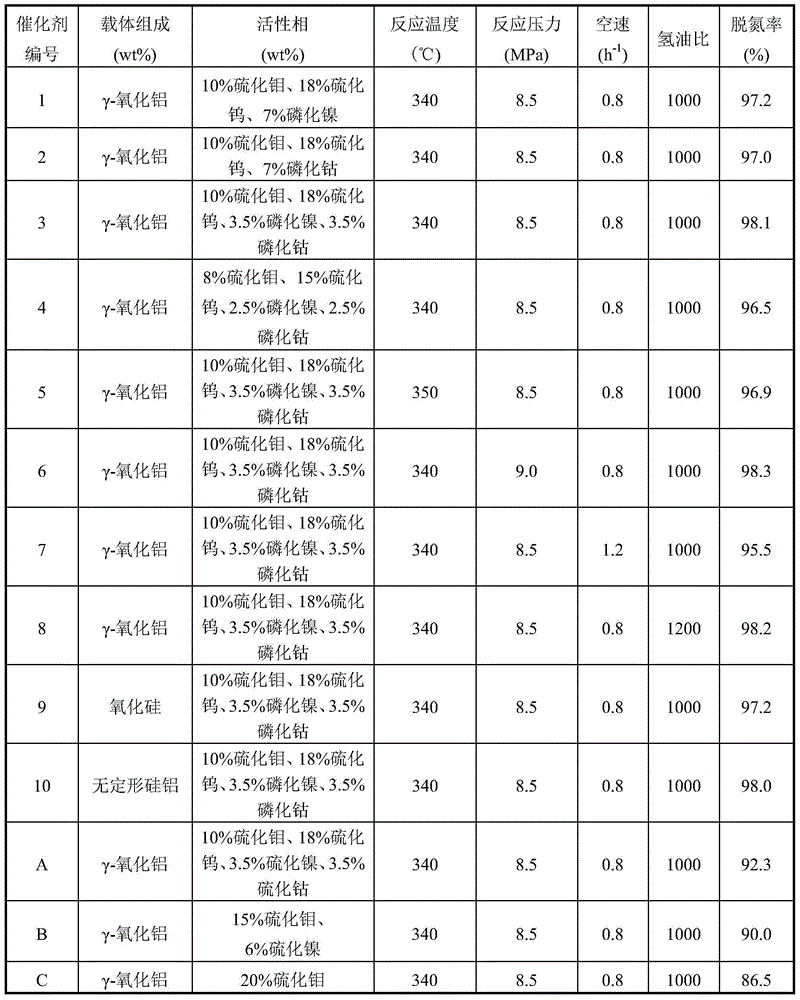

Embodiment 1

[0034] Add 2.4g of scallop powder to 80g of gamma-alumina (Shandong Zibo Qilin Chemical Co., Ltd.) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0035] The ammonium tetrathiomolybdate and ammonium tetrathiotungstate solutions are used to impregnate the carrier particles at 40°C, and the contents of molybdenum sulfide and tungsten sulfide contained in the impregnation solution are respectively 10% and 18% of the dry weight of the carrier. After aging for 8 hours and drying, the nickel hypophosphite solution is used to impregnate the carrier particles at 40°C. The converted nickel phosphide content in the impregnat...

Embodiment 2

[0038] Add 2.4g of scallop powder to 80g of gamma-alumina (Shandong Zibo Qilin Chemical Co., Ltd.) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0039]The ammonium tetrathiomolybdate and ammonium tetrathiotungstate solutions are used to impregnate the carrier particles at 40°C, and the contents of molybdenum sulfide and tungsten sulfide contained in the impregnation solution are respectively 10% and 18% of the dry weight of the carrier. After aging for 8 hours and drying, impregnate the carrier particles with cobalt hypophosphite solution at 40°C. The converted cobalt phosphide content in the impregnating solutio...

Embodiment 3

[0042] Add 2.4g of scallop powder to 80g of gamma-alumina (Shandong Zibo Qilin Chemical Co., Ltd.) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0043] The ammonium tetrathiomolybdate and ammonium tetrathiotungstate solutions are used to impregnate the carrier particles at 40°C, and the contents of molybdenum sulfide and tungsten sulfide contained in the impregnation solution are respectively 10% and 18% of the dry weight of the carrier. After aging for 8 hours and drying, impregnate the carrier particles with nickel hypophosphite and cobalt hypophosphite solutions at 40°C. The converted contents of nickel phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com