Light cycle oil hydrodesulfurization catalyst and preparation method thereof

A light cycle oil, hydrodesulfurization technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of large environmental pollution, removal of light cycle oil sulfides, high operating costs, etc. , to achieve high desulfurization rate, cost saving, simple activation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

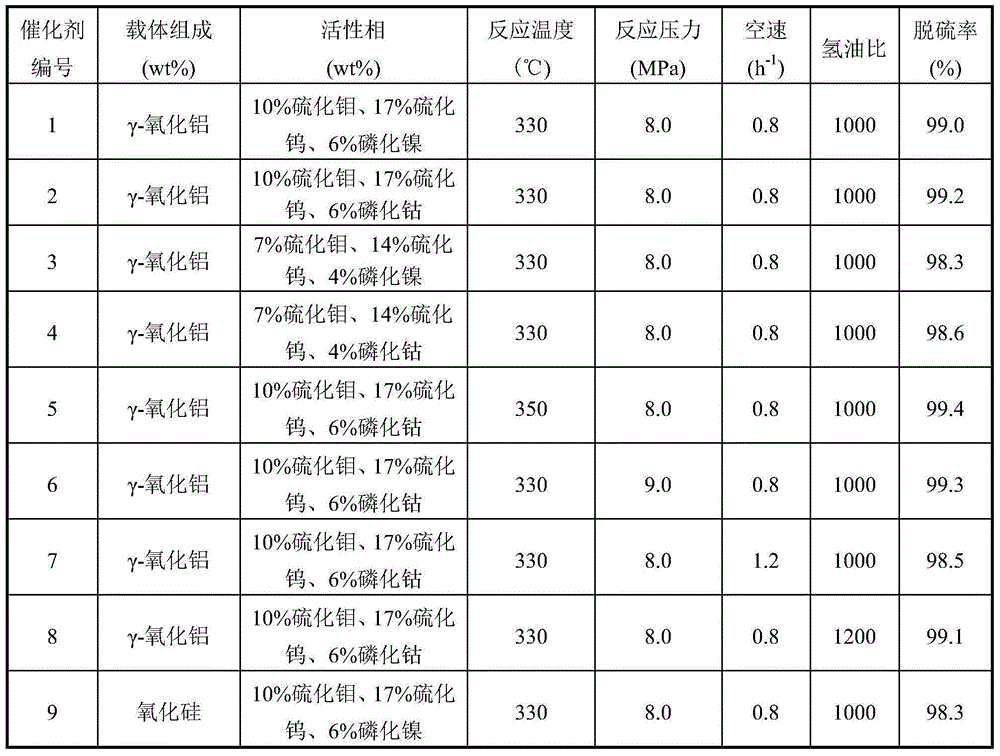

Embodiment 1

[0035] Add 2.4g of scallop powder to 80g of gamma-alumina (Shandong Zibo Qilin Chemical Co., Ltd.) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0036] The ammonium tetrathiomolybdate and ammonium tetrathiotungstate solutions are used to impregnate the carrier particles at 40°C, and the contents of molybdenum sulfide and tungsten sulfide contained in the impregnation solution are respectively 10% and 17% of the dry weight of the carrier. After aging for 8 hours and drying, impregnate the carrier particles with nickel hypophosphite solution at 40°C. The converted nickel phosphide content in the impregnating soluti...

Embodiment 2

[0039] Add 2.4g of scallop powder to 80g of gamma-alumina (Shandong Zibo Qilin Chemical Co., Ltd.) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0040] The ammonium tetrathiomolybdate and ammonium tetrathiotungstate solutions are used to impregnate the carrier particles at 40°C, and the contents of molybdenum sulfide and tungsten sulfide contained in the impregnation solution are respectively 10% and 17% of the dry weight of the carrier. After aging for 8 hours and drying, impregnate the carrier particles with cobalt hypophosphite solution at 40°C. The converted cobalt phosphide content in the impregnating solutio...

Embodiment 3

[0043] Add 2.4g of scallop powder to 80g of gamma-alumina (Shandong Zibo Qilin Chemical Co., Ltd.) on a dry basis and mix well, then add 4g of HNO at a volume ratio of 1:1 3 aqueous solution and 40g deionized water, and knead evenly to make a dough suitable for extrusion. It is extruded through a die and is in the shape of a slender cylinder (cross-sectional diameter 1.5mm). After drying at 120°C, it is baked at 550°C for 4 hours, and then it is cut into carrier particles (1.5×4.0mm) of uniform size for use.

[0044] The ammonium tetrathiomolybdate and ammonium tetrathiotungstate solutions are used to impregnate the carrier particles at 40°C, and the contents of molybdenum sulfide and tungsten sulfide contained in the impregnation solution are respectively 7% and 14% of the dry weight of the carrier. After aging for 8 hours and drying, impregnate the carrier particles with nickel hypophosphite solution at 40°C. The converted nickel phosphide content in the impregnation solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com