A kind of tio2-pd-ppy composite photocatalyst and its preparation method and application

A technology of tio2-pd-ppy and compound light, which is applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, chemical instruments and methods, etc., can solve the problem of inability to achieve precise positioning of Pd and PPy loads, Poor photocatalytic performance of photocatalysts, complex synthesis conditions and other problems, to achieve high commercial application prospects, simple and fast synthesis methods, and good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

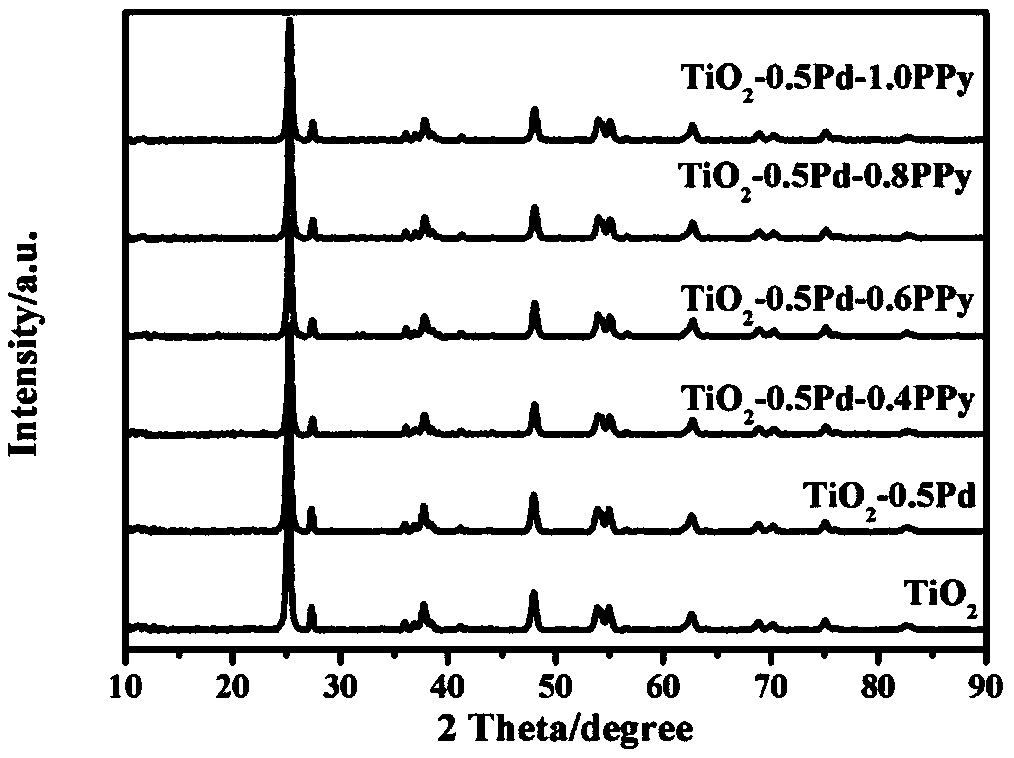

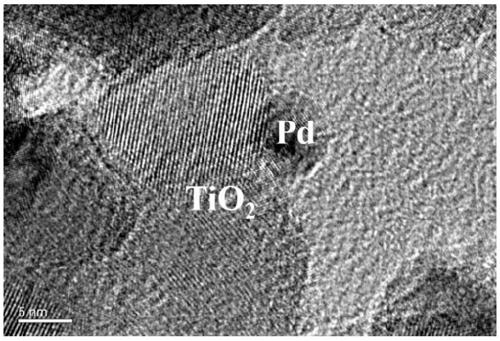

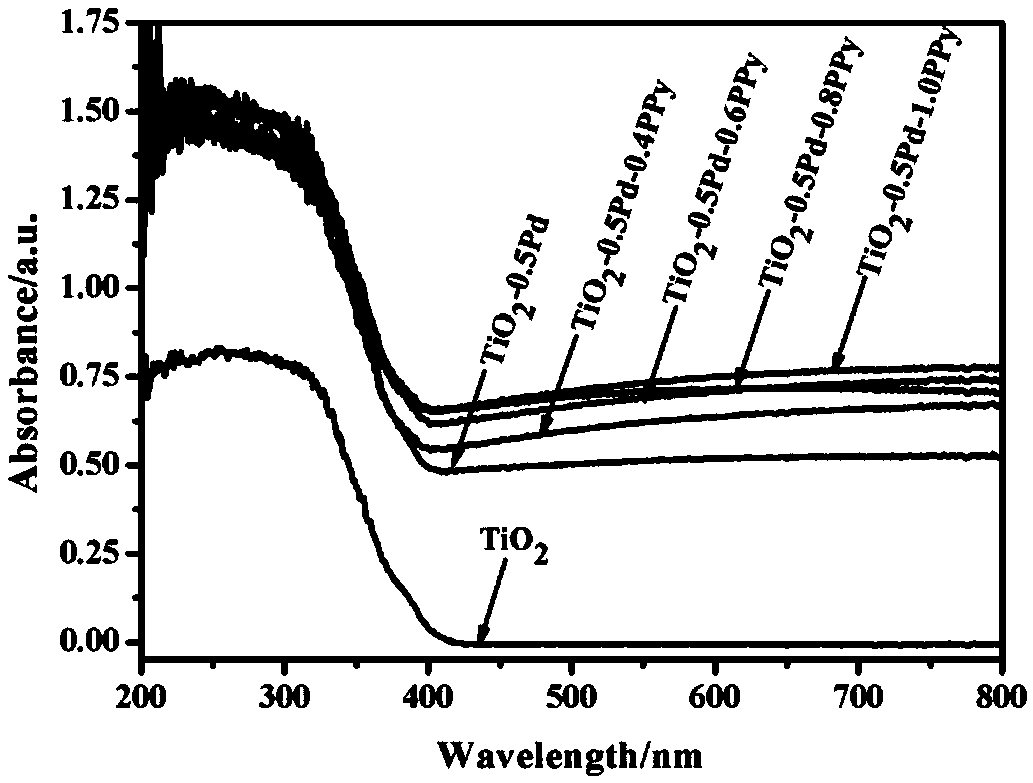

[0039] Weigh TiO 2 Add 300 mg of (P25) into 100 mL of deionized water, and sonicate for 5 minutes to form a uniform suspension. Under constant stirring conditions, the TiO 2 Add 250 μL palladium chloride (PdCl 2 , 0.0564mol / L) and 1.2×10 -2 -3.0×10 -2 mg pyrrole (Py) monomer. Among them, relative to TiO 2 , the mass fractions of Pd and PPy are 0.5wt% and 0.2wt%, 0.4wt%, 0.6wt%, 0.8wt%, 1.0wt%. Then, high-purity nitrogen gas was passed thereinto for 30 minutes to remove dissolved oxygen therein. Finally, use a 300W xenon lamp to irradiate with full light for 30 minutes, filter the obtained sample, wash it several times with deionized water and absolute ethanol, and dry it in an air atmosphere at 60°C for 12 hours to obtain TiO 2 -Pd-PPy composite photocatalyst.

[0040] Replace the pyrrole monomer with methanol, adjust the pH of the reaction solution to 3.0 with 1.0mol / L sodium hydroxide, and follow the same steps as above to obtain the comparative sample TiO 2 -0.5Pd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com