An anaerobic built-in rusty iron filings reactor for efficient removal of ammonia nitrogen and its process for treating ammonia nitrogen wastewater

A reactor and ammonia removal technology, applied in anaerobic digestion treatment, electrochemical biological combination treatment, water/sewage treatment, etc., can solve the problems of low removal efficiency, long time-consuming anaerobic ammonia nitrogen removal, etc., to reduce the cost and cost , processing capacity and stability enhancement, and the effect of promoting anaerobic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

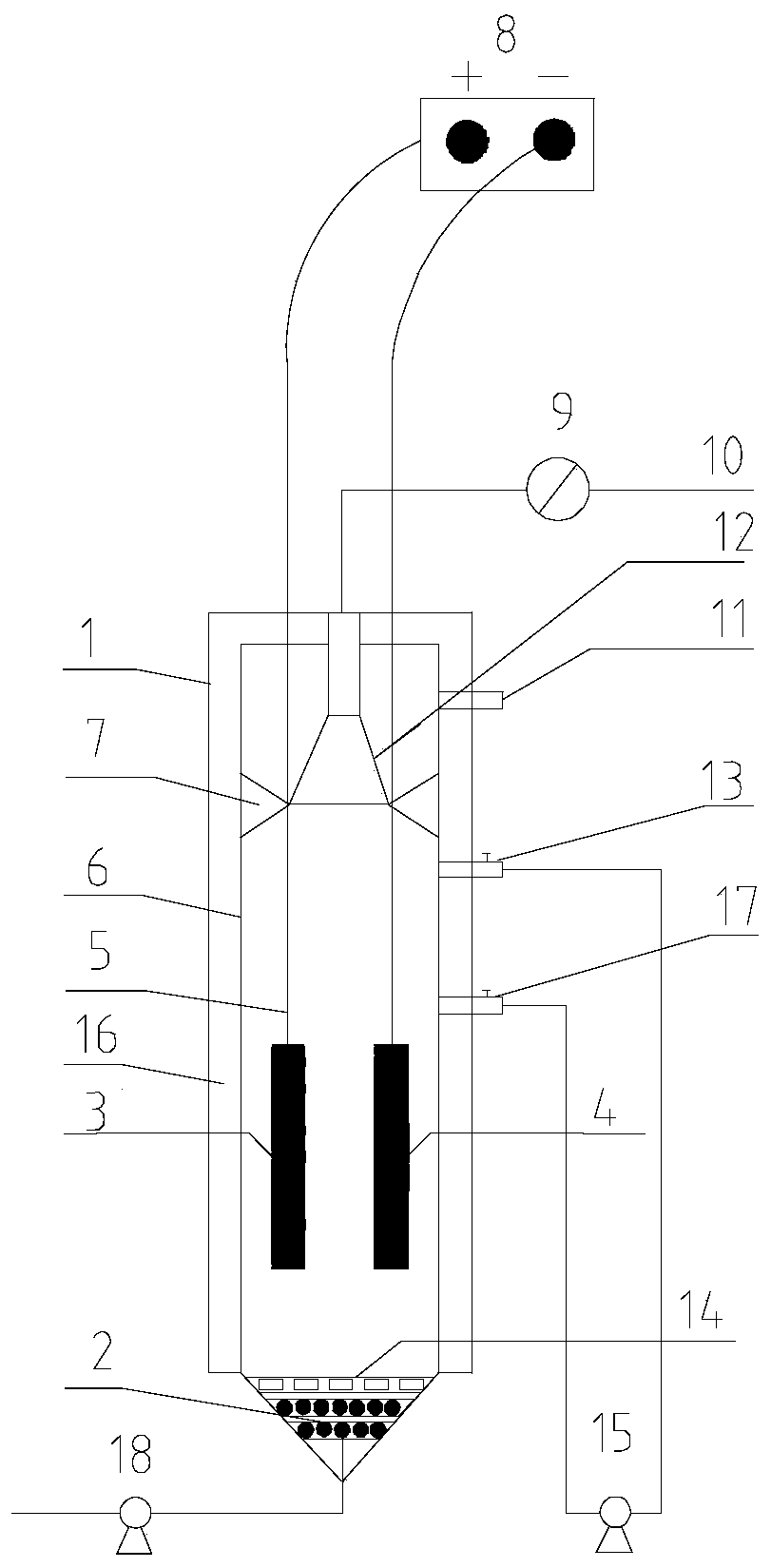

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. attached figure 1 It is a structural schematic diagram of an anaerobic built-in rusty iron chip reactor for efficiently removing ammonia nitrogen in the present invention. It includes a box body 1, an anaerobic sludge layer 2, rusty iron filings 14, and a reactor inner chamber 6. A circulating water cavity 16 is provided between the box body 1 and the reactor inner cavity 6 . The electrode anode 3 (carbon brush) and electrode cathode 4 (carbon rod) fixed below the reactor inner chamber 6 are respectively connected to the positive and negative poles of the power supply 8 through wires 5 . A baffle 7 is arranged above the inner cavity 6 of the reactor and a three-phase separator 12 is fixed on the upper end thereof, and the upper end of the three-phase separator 12 communicates with an outlet pipe 10 through a gas flow meter 9 . The inner cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com