Cementing material prepared from oil-bearing sludge, preparation method and application of cementing material and cement prepared from cementing material

A technology of cementitious materials and sludge, which is applied in the field of cement, can solve the problems of soil, water and air pollution, products that cannot be directly used, and incomplete treatment, etc., and achieve the effects of short calcination cycle, low production cost and complete raw material treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

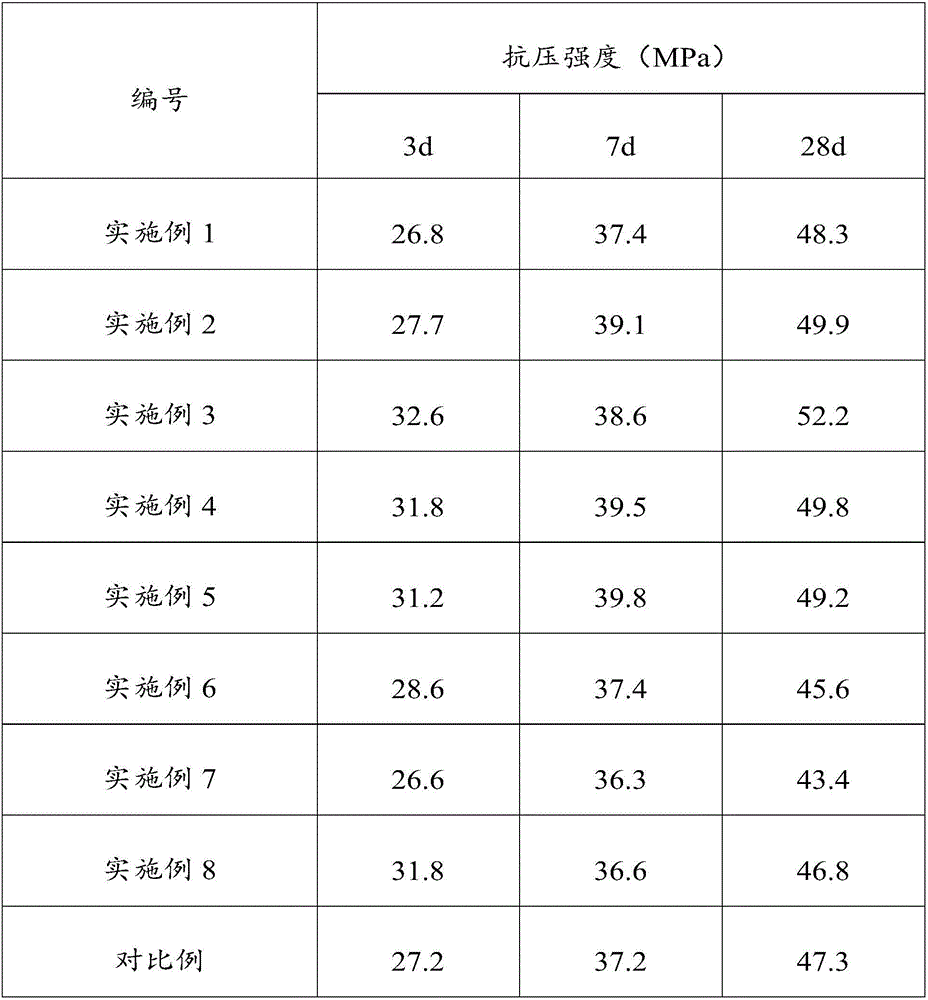

Examples

preparation example Construction

[0021] The preparation method of the above-mentioned cementitious material includes: preparing the first raw material and the second raw material, adding water and stirring them into balls, calcining the balls at 1000-1100° C. for 0.5-1 hour, and pulverizing after cooling.

[0022] The preparation method of the gelling material provided by the invention only needs to dry the raw materials, pulverize them, mix them evenly and then calcinate them, and the process is simple and the energy consumption is low. The calcination time is only 0.5-1h, the production cycle is short and the efficiency is high. During the preparation process, no solid waste residue is discharged, and the treatment of oily sludge and steel slag is complete.

[0023] During the calcination process, the material balls fully undergo chemical reactions under high temperature conditions, causing corrosion to the sludge, destroying the original structure of harmful substances in the sludge, and killing pathogenic...

Embodiment 1

[0036] A method for preparing cement prepared from oily sludge, comprising:

[0037] Preparing the cementitious material: drying and pulverizing the oily sludge to a particle size of less than 80 μm to obtain the first raw material; drying and pulverizing the steel slag to a particle size of less than 80 μm to obtain the second raw material. Weigh 90 kg of the first raw material and 10 kg of the second raw material, add water, mix and stir to form pellets with a particle diameter of 8 mm. Dry the pellets at 100°C, then heat-preserve and calcinate at 1000°C for 0.5h, cool with blowing air, and crush until the particle size is less than 80μm.

[0038] 10kg of the above cementitious material, 5kg of dihydrate gypsum and 85kg of cement clinker were weighed and mixed to obtain cement prepared from oily sludge.

Embodiment 2

[0040] A method for preparing cement prepared from oily sludge, comprising:

[0041] Preparing the cementitious material: drying and pulverizing the oily sludge to a particle size of less than 80 μm to obtain the first raw material; drying and pulverizing the steel slag to a particle size of less than 80 μm to obtain the second raw material. Weigh 80kg of the first raw material and 20kg of the second raw material, add water, mix and stir to form pellets with a particle diameter of 10mm. Dry the pellets at 100°C, then heat-preserve and calcinate at 1000°C for 0.5h, cool with air, and crush until the particle size is less than 80μm.

[0042] Weighing 10kg of the above-mentioned cementitious material, 5kg of dihydrate gypsum and 85kg of cement clinker were mixed to obtain cement prepared from oily sludge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com