Crack-resistant penetration-resistant agent for concrete and preparation method of crack-resistant penetration-resistant agent for concrete

An anti-seepage agent and concrete technology, which is applied in the field of concrete admixtures, can solve the problems of poor graphene dispersion and weak bonding force between sulfonated graphene and concrete, so as to improve the impermeability, flexural, tensile and crack resistance, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

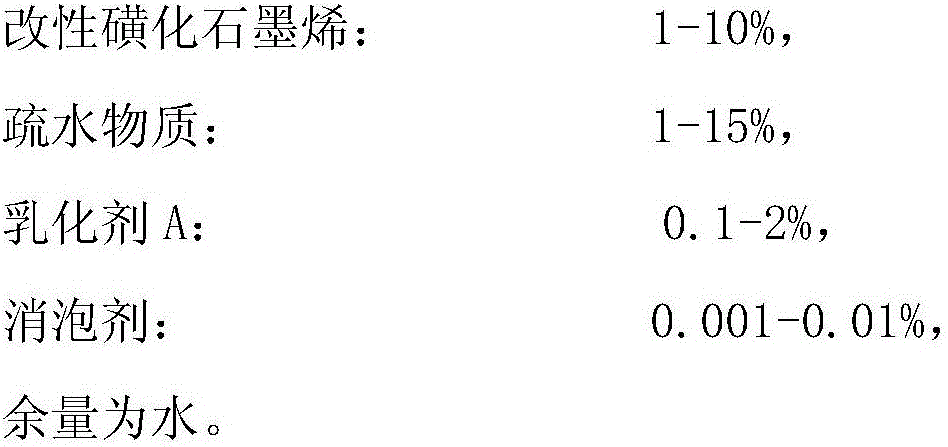

Method used

Image

Examples

Embodiment 1

[0022] Take 3.1g of γ-aminopropyltriethoxysilane, 70g of sulfonated graphene aqueous solution with a mass concentration of 10%, and 0.035g of emulsifier Tween 60, mix them evenly and add them to Reactor 1, heat to 40°C, and stir at 40°C 6h, the stirring speed is 300rpm, and the modified sulfonated graphene emulsion is obtained.

[0023] The above-mentioned modified sulfonated graphene emulsion 73.1g, n-decyl alcohol 10g, Pingpingjia 151g, defoamer 0.01g and water 905.6g were added in the shear kettle 2 and stirred at room temperature under 2000rpm for 1h to obtain concrete crack resistance penetrating agent.

Embodiment 2

[0025] Take 9.5g of γ-aminopropyltriethoxysilane, 210g of sulfonated graphene aqueous solution with a mass concentration of 10%, and 0.21g of emulsifier Tween 80, mix them evenly and add them to Reactor 1, heat to 50°C, and stir at 50°C 8h, the stirring speed is 700rpm, and the modified sulfonated graphene emulsion is obtained.

[0026] The above-mentioned modified sulfonated graphene emulsion 219.7g, undecyl alcohol 70g, Pingpingjia 255g, defoamer 0.03g and water 674.6g were added in the shear kettle 2 and stirred at room temperature under 2500rpm for 1h to obtain concrete crack resistance penetrating agent.

Embodiment 3

[0028] Take 15.3g of γ-aminopropyltrimethoxysilane, 340g of sulfonated graphene aqueous solution with a mass concentration of 10%, and 0.68g of emulsifier EL-40, mix them evenly and add them to Reactor 1, heat to 60°C, and stir at 60°C for 10h , the stirring speed is 1200rpm, and the modified sulfonated graphene emulsion is obtained.

[0029] The above-mentioned modified sulfonated graphene emulsion 356.0g, dodecyl alcohol 140g, Pingpingjia 25 10g, defoamer 0.07g and water 444.0g were added in the shear kettle 2 and stirred at room temperature under 3000rpm for 2h to obtain concrete crack resistance penetrating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com