Sand-based breathing bricks and manufacturing method thereof

A production method and technology of breathing bricks, which can be applied to other household appliances, sustainable waste treatment, solid waste management, etc., can solve the problems of affecting the performance of diatomite, increasing production costs, and failure to achieve separation, so as to alleviate desertification, Energy-saving and strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

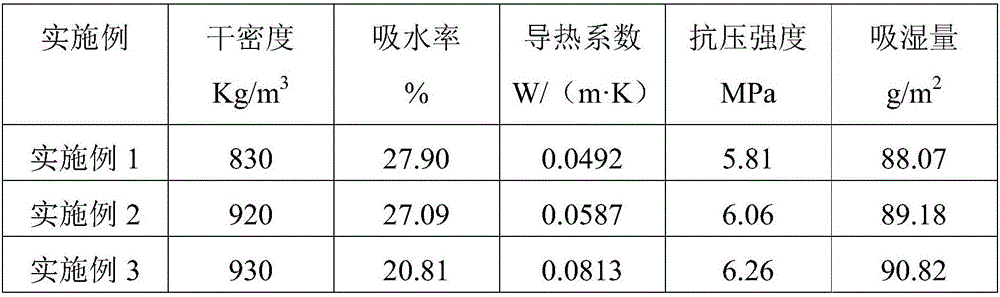

Embodiment 1

[0038] The major ingredients described in this embodiment are composed of the following components by mass percentage:

[0039] Gelling agent: 35%;

[0040] Desert Sand: 23%;

[0041] Fly ash: 25%;

[0042] Slag: 14%;

[0043] Humidity-conditioning material: 3.0%;

[0044]The admixture is composed of the following components according to the mass percentage of the main ingredient:

[0045] Water reducing agent: 0.5%;

[0046] Foaming agent: 3.0%;

[0047] Foam stabilizer: 0.5%;

[0048] The humidity-adjusting slurry needs to be prepared separately, and its proportioning consists of the following components:

[0049] The humidity-adjusting slurry is composed of humidity-adjusting materials, latex powder, suspending agent, and water in a mass ratio of 0.8:0.15:0.05:100.

[0050] Preparation:

[0051] ①Material preparation: The slag is crushed and ground, and its particle size is controlled below 0.15mm; the desert sand and fly ash are respectively ground, and their part...

Embodiment 2

[0059] The major ingredients described in this embodiment are composed of the following components by mass percentage:

[0060] Gelling agent: 40%;

[0061] Desert Sand: 28%;

[0062] Fly ash: 18%;

[0063] Slag: 10.5%;

[0064] Humidity-conditioning material: 3.5%;

[0065] The admixture is composed of the following components according to the mass percentage of the main ingredient:

[0066] Water reducing agent: 0.4%;

[0067] Foaming agent: 2.8%;

[0068] Foam stabilizer: 0.4%;

[0069] The humidity-adjusting slurry needs to be prepared separately, and its proportioning consists of the following components:

[0070] The humidity-adjusting slurry is composed of humidity-adjusting materials, latex powder, suspending agent, and water in a mass ratio of 0.8:0.15:0.05:100.

[0071] Preparation:

[0072] ①Material preparation: The slag is crushed and ground, and its particle size is controlled below 0.125mm; the desert sand and fly ash are respectively ground, and their ...

Embodiment 3

[0080] The major ingredients described in this embodiment are composed of the following components by mass percentage:

[0081] Gelling agent: 45%;

[0082] Desert Sand: 33%;

[0083] Fly ash: 10%;

[0084] Slag: 8%;

[0085] Humidity-conditioning material: 4.0%;

[0086] The admixture is composed of the following components according to the mass percentage of the main ingredient:

[0087] Water reducer: 0.3%;

[0088] Foaming agent: 2.5%;

[0089] Foam stabilizer: 0.3%;

[0090] The humidity-adjusting slurry needs to be prepared separately, and its proportioning consists of the following components:

[0091] The humidity-adjusting slurry is composed of humidity-adjusting materials, latex powder, suspending agent, and water in a mass ratio of 0.8:0.15:0.05:100.

[0092] Preparation:

[0093] ①Material preparation: the slag is crushed and ground, and its particle size is controlled below 0.10mm; the desert sand and fly ash are respectively ground, and their particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com