Rare earth compound and preparation method thereof

A technology of rare earth compounds and carboxylic acid compounds, applied in the field of polymerization, can solve the problems of low catalytic efficiency and high impurity content of rare earth catalysts, and achieve the effects of low production cost, low impurity content and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

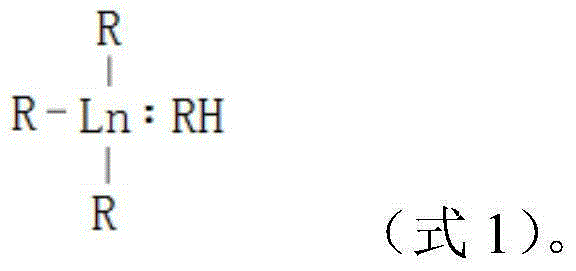

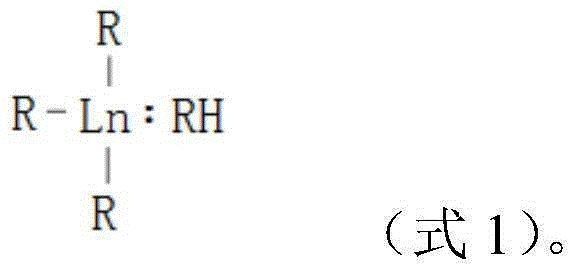

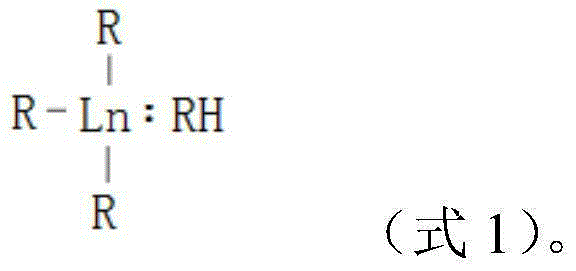

[0022] In the second aspect, the present invention provides a method for preparing a rare earth compound, the method comprising: in the presence of an inert solvent, under the condition of dehydration and reflux, contacting a rare earth metal salt with a carboxylic acid compound to obtain a rare earth compound, wherein the The rare earth metal salt is Ln(M) 3 ; M is acetate, nitrate or sulfate; Ln is a lanthanide; the carboxylic acid compound is HR, and R is a carboxylate with 7-12 carbon atoms.

[0023] The above preparation method of the present invention has the advantage of low production cost, and the rare earth catalyst prepared by using the rare earth compound prepared by the above method of the present invention has the advantage of high catalytic efficiency.

[0024] In the present invention, the rare earth metal salt can exist in the form of hydrate. That is to say, the rare earth metal salt described in the present invention includes its hydrate form.

[0025] In ...

Embodiment 1

[0058] This example is used to illustrate the method for preparing rare earth compounds of the present invention. specifically:

[0059] Add 0.01mol of neodymium acetate (Nd(OAc) to 100mL of chlorobenzene 3 ·6H 2 (0) and 0.04mol of neodecanoic acid, and add 5g of Molecular sieves, and then heated to reflux for 7 hours. After the obtained reactant was distilled off under reduced pressure to remove the solvent, an appropriate amount of hexane solvent was added to dissolve it into a rare earth compound solution with a concentration of 0.5 mol / L for use.

Embodiment 2

[0061] This example is used to illustrate the method for preparing rare earth compounds of the present invention. specifically:

[0062] To 100mL of toluene was added 0.01mol of neodymium acetate (Nd(OAc) 3 ·6H 2 O) and 0.05mol of cyclohexyl formic acid, and add 6g of Molecular sieves, and then heated to reflux for 10 hours. After the obtained reactant was distilled off under reduced pressure to remove the solvent, an appropriate amount of cyclohexane solvent was added to dissolve it into a rare earth compound solution with a concentration of 0.5 mol / L for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com