Compound type macromolecular light stabilizer based on Diels-Alder click chemistry and preparation method thereof

A technology of light stabilizer and click chemistry, which is applied in the field of compound macromolecular light stabilizer and its preparation, can solve problems such as human health threats, achieve good compatibility, excellent broad-spectrum ultraviolet absorption function, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

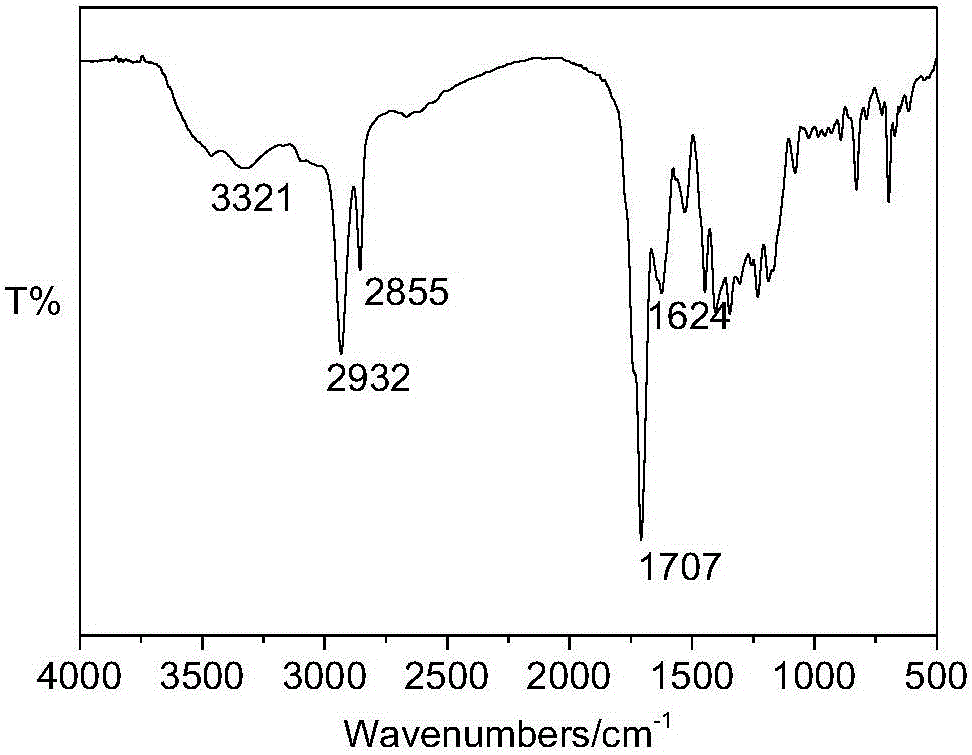

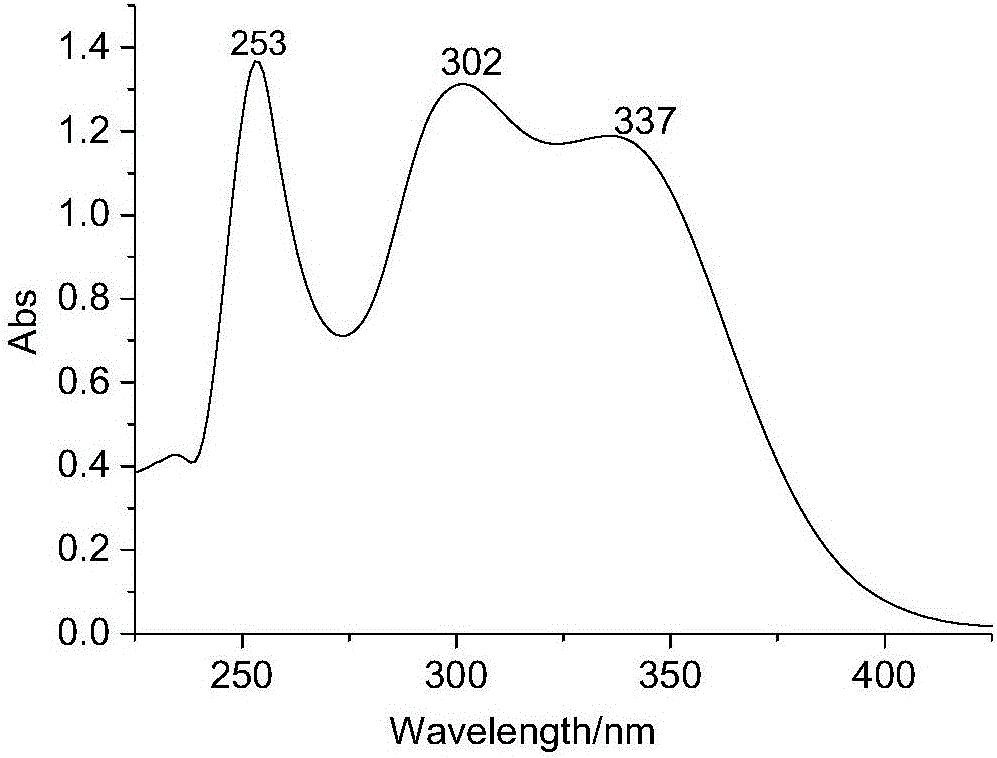

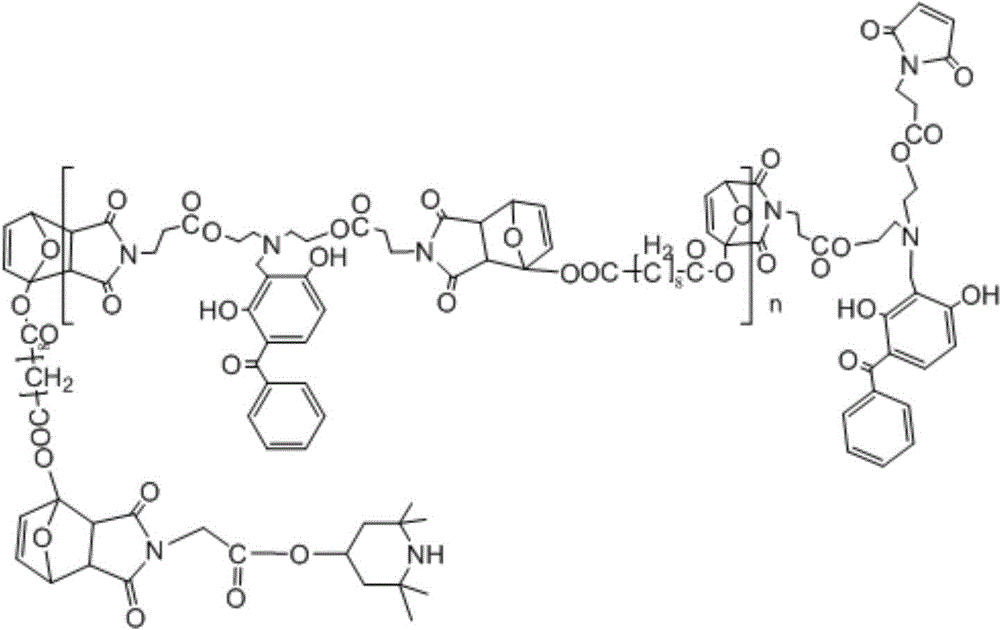

[0027] The invention provides a compound type macromolecular light stabilizer based on Diels-Alder click chemistry and a preparation method thereof, comprising: utilizing 3-(N, N,-2-maleimido ethyl propionate-amine Diels-Alder reaction of methyl)-2,4-dihydroxybenzophenone and bisfurfuryl sebacate as raw material monomers, and then adding 2,2,6,6-tetramethylpiperidinol maleyl The imine propionate is used as an end-capping agent to carry out end-capping to prepare a composite macromolecular light stabilizer, wherein the addition amount of the end-capping agent is 0.1-2% of the total weight of the raw material monomers.

[0028] The molecular chain of the composite macromolecular light stabilizer prepared by the preparation method of the compound macromolecular light stabilizer based on Diels-Alder click chemistry of the present invention is a heterochain, which has excellent broad-spectrum ultraviolet absorption function; Different end-capping agents can be used for chain end gr...

Embodiment 1

[0039] (1) Synthesis of 3-(N, N,-2-hydroxyethyl-aminomethyl)-2,4-dihydroxybenzophenone (HAHBP)

[0040] UV-0: diethanolamine=1: 1.2 (mol); UV-0: paraformaldehyde=1: 1.4 (mol),

[0041] Put 1.26g (0.012mol) of diethanolamine into a 150mL three-necked flask, and start to add 0.42g (0.014) of paraformaldehyde powder in batches when heating at 60°C, and put in 0.14g of paraformaldehyde every 15 minutes, and put it in 3 batches. After the addition, the temperature was raised to 70°C for 1.0 h, then 2.14 g (0.01 mol) of UV-0 was dissolved in 8 mL of methanol, added to the above reaction solution, and the reaction was continued at 70°C for 2.5 h. Then the product is washed with water to remove excess diethanolamine and paraformaldehyde, freeze-dried, and the synthetic route is:

[0042]

[0043] (2) Synthesis of 3-(N,N,-2-ethyl maleimidopropionate-aminomethyl)-2,4-dihydroxybenzophenone (EMIPAHBP)

[0044] MIPA:HAHBP=2.0:1, MIPA:DCC=1:1 (mol).

[0045] In a 150mL three-necked fl...

Embodiment 2

[0059] (1) Synthesis of 3-(N, N,-2-hydroxyethyl-aminomethyl)-2,4-dihydroxybenzophenone (HAHBP)

[0060] UV-0: diethanolamine=1: 2.0 (mol): UV-0: paraformaldehyde=1: 1.5 (mol),

[0061] Put 2.23g (0.0212mol) of diethanolamine into a 150mL three-necked flask, and start adding paraformaldehyde powder in batches at 70°C, a total of 0.99g (0.033mol), and put in 0.2475g of paraformaldehyde every 15min, and put it in 4 batches After the addition, the temperature was raised to 80°C for 2.5h, and then 2.27g (0.0106mol) of UV-0 was dissolved in 15mL of methanol, added to the above reaction solution, and kept at 80°C for 5h. Then the product is washed with water to remove excess diethanolamine and paraformaldehyde, freeze-dried (vacuum-dried), and the synthetic route is:

[0062]

[0063] (2) Synthesis of 3-(N,N,-2-ethyl maleimidopropionate-aminomethyl)-2,4-dihydroxybenzophenone (EMIPAHBP)

[0064] MIPA:HAHBP=2.5:1, MIPA:DCC=1:1 (mol).

[0065] In a 150mL three-necked flask, add 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com