Rubber improving vulcanization system and preparation method and application of rubber

A vulcanization system and rubber technology, which is applied in the field of rubber materials for tires, can solve the problems of vulcanization and reversion of tire tread rubber, and achieve the effects of avoiding vulcanization and reversion, excellent performance, and prolonging durability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

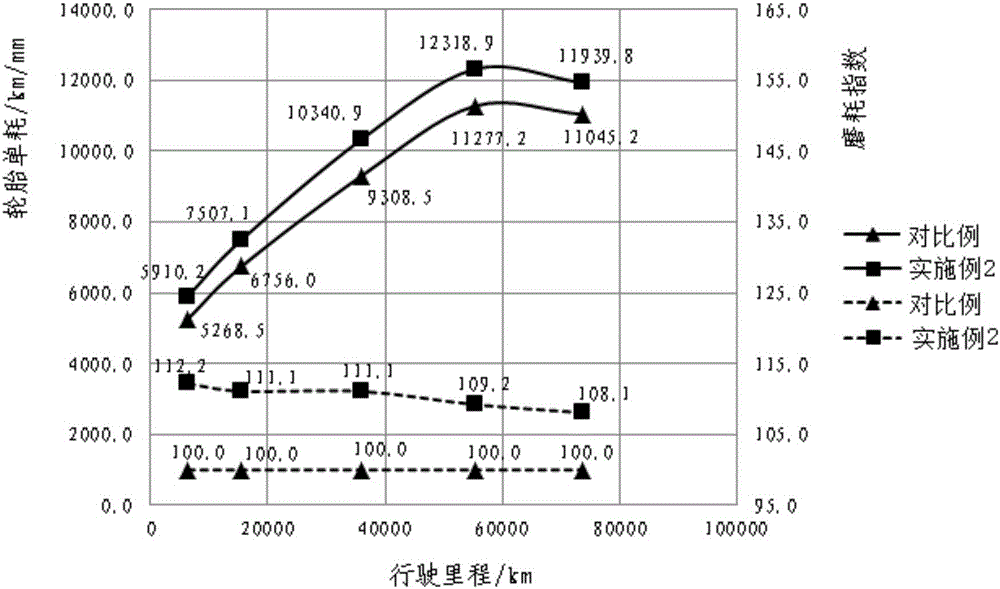

Examples

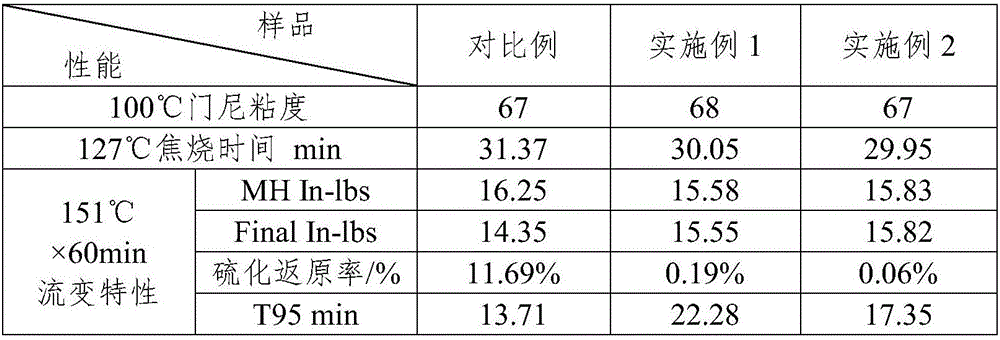

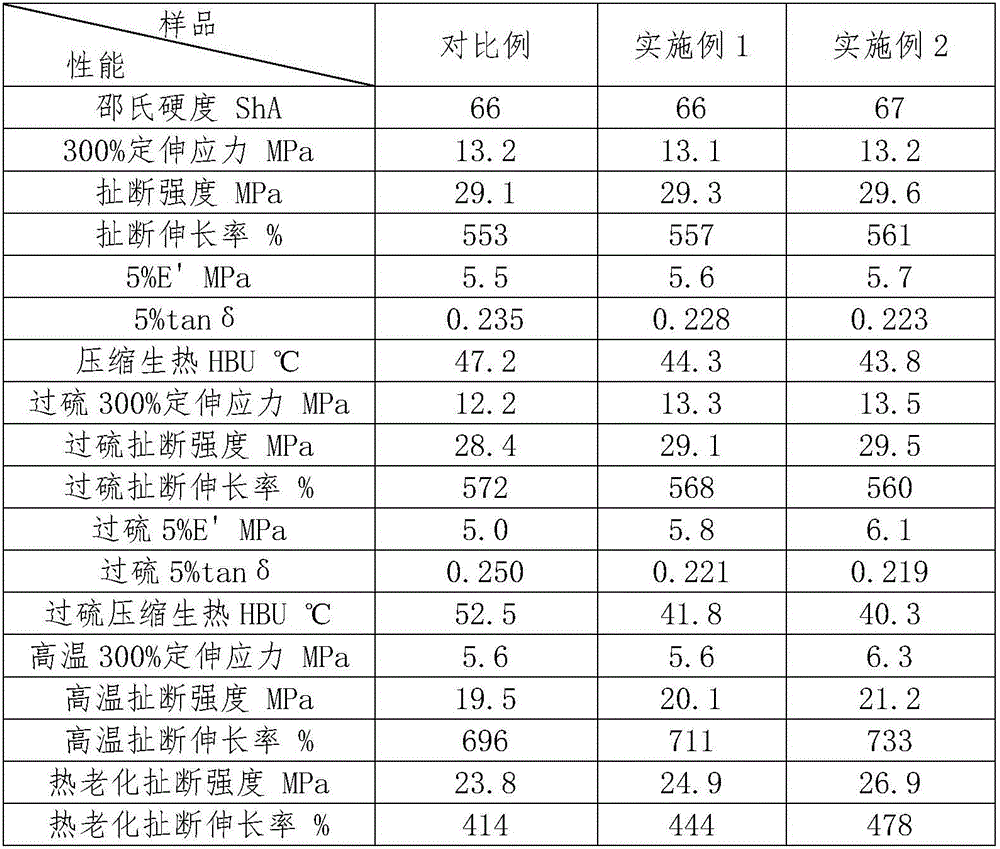

Embodiment 1

[0030] The rubber of the modified vulcanization system in this embodiment is made of the following raw materials in parts by weight: 100 parts of natural rubber, 0.1 part of peptizer, 53 parts of carbon black, 4 parts of zinc oxide, 2.3 parts of stearic acid, 4 parts of anti-aging agent, 0.9 parts of crystal wax, 2 parts of dispersant, 1.5 parts of sulfur, 1.2 parts of accelerator, 2.5 parts of bis-(γ-triethoxysilylpropyl) tetrasulfide, 0.2 parts of anti-scorch agent CTP.

[0031] The anti-aging agent is anti-aging agent 4020, anti-aging agent RD, and anti-aging agent DTPD according to 2 parts of anti-aging agent 4020, 1 part of anti-aging agent RD, and 1 part of anti-aging agent DTPD;

[0032] The peptizer is peptizer WP-10; the dispersant is dispersant FS-97; the carbon black is N115 carbon black; the accelerator is accelerator TBBS; elemental sulfur exists as S8 ring molecule, and the molar mass is 256.5g / mol , the molar mass of accelerator TBBS is 238.4g / mol, and the molar...

Embodiment 2

[0040] The rubber of the modified vulcanization system in this embodiment is made of the following raw materials in parts by weight: 100 parts of natural rubber, 0.1 part of peptizer, 53 parts of carbon black, 4 parts of zinc oxide, 2.3 parts of stearic acid, 4 parts of anti-aging agent, 0.9 parts of crystal wax, 2 parts of dispersant, 1.5 parts of sulfur, 1.5 parts of accelerator, 2.5 parts of bis-(γ-triethoxysilylpropyl) tetrasulfide, 0.2 parts of anti-scorch agent CTP.

[0041] The anti-aging agent is anti-aging agent 4020, anti-aging agent RD, and anti-aging agent DTPD according to 2 parts of anti-aging agent 4020, 1 part of anti-aging agent RD, and 1 part of anti-aging agent DTPD;

[0042] The peptizer is peptizer WP-10; the dispersant is dispersant FS-97; the carbon black is N115 carbon black; the accelerator is the combination of accelerator TBBS and accelerator CZ, and the molar ratio of accelerator TBBS to accelerator CZ The ratio is 2:1; elemental sulfur exists as S8 c...

Embodiment 3

[0074] The rubber of the modified vulcanization system in this embodiment is made of the following raw materials in parts by weight: 80 parts of natural rubber, 0.1 part of peptizer, 50 parts of carbon black, 3 parts of zinc oxide, 1.5 parts of stearic acid, 0.5-2 parts of sulfur, Accelerator 0.5 parts, bis-(γ-triethoxysilylpropyl) tetrasulfide 1.5 parts.

[0075] Wherein the peptizer is peptizer WP-10; the carbon black is N115 carbon black or SAF carbon black; the accelerator is accelerator TBBS;

[0076] This embodiment improves the preparation method of the rubber of vulcanization system, comprises the following steps:

[0077] S1. Weigh each raw material in parts by weight, add natural rubber, peptizer, zinc oxide, and stearic acid into the mixer, pressurize and knead the top bolt for 20SS, lift the bolt and add carbon black, and add the amount of carbon black It is 50% of the total mass of carbon black, then pressurize and knead with the top bolt for 25S, add the remaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com