Foam composition and preparation method of the same

A kind of composition, the technology of foaming agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

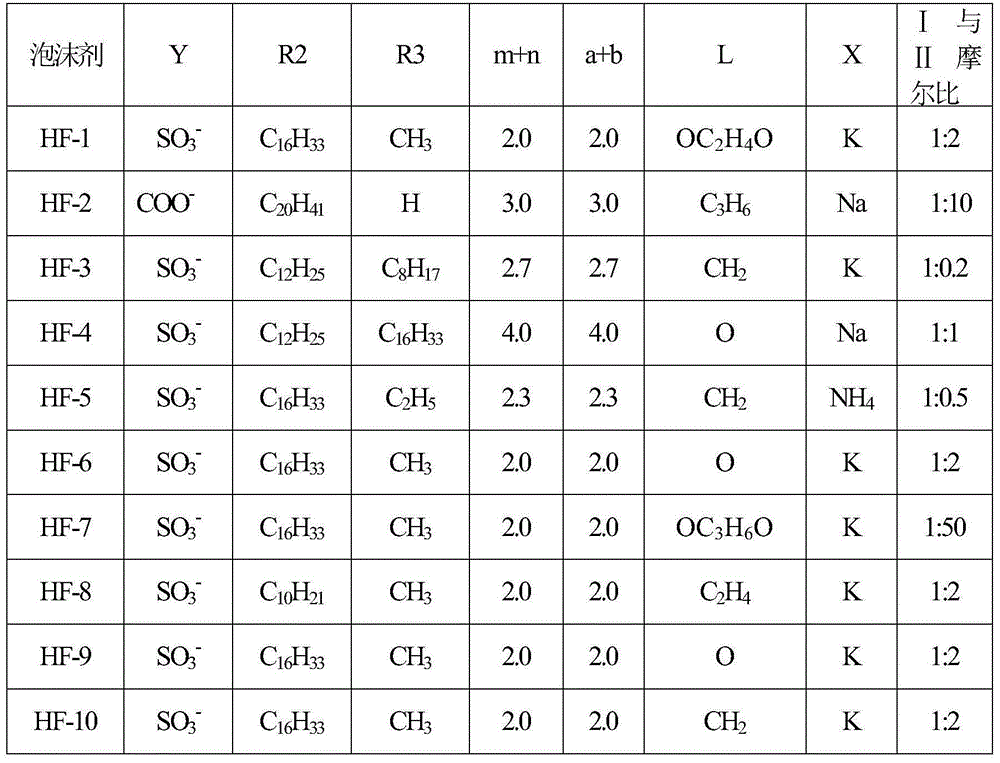

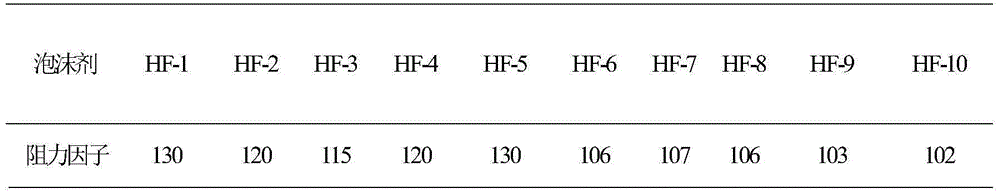

Examples

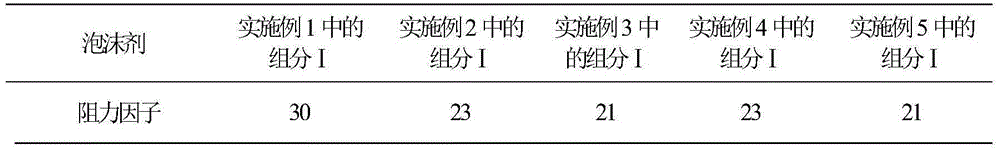

Embodiment 1

[0039] The preparation of composition HF-1, preparation steps:

[0040] (1) Long-chain polyether nitrogen-containing compound (C 12 h 25 O(CHCH 3 CH 2 O) 3 (CH 2 CH 2 O) 7 CH 2 CH 2 N(CH 3 ) 2 C 3 h 6 OSO 3 ) synthesis and preparation:

[0041] Add 186.0 grams of dodecanol and 5.6 grams of potassium hydroxide to a pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, dehydrate under high vacuum for 1 hour, and then replace with nitrogen for 3- 4 times, adjust the reaction temperature of the system to 150 ° C and slowly pass 179.9 grams of propylene oxide, control the pressure ≤ 0.60 MPa, lower the temperature to 90 ° C, remove low boilers in vacuum, continue to adjust the reaction temperature of the system to 150 ° C and slowly pass Inject 360.0 grams of ethylene oxide and control the pressure to ≤0.60MPa. After the reaction, neutralize and dehydrate after cooling to obtain C 12 h 25 O(CHCH 3 CH 2 O) 3 (CH 2...

Embodiment 2

[0048] The preparation of composition HF-2, preparation steps:

[0049] (1) Long-chain polyether nitrogen-containing compound (C 16 h 33 O(CHCH 3 CH 2 O) 10 (CH 2 CH 2 O) 20 CH 2 CH 2 N(C 2 h 5 )(C 3 h 7 O)CH 2 COO) synthesis and preparation:

[0050] Add 121 grams of cetyl alcohol and 3 grams of potassium hydroxide to a pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, dehydrate under high vacuum for 1 hour, and then replace with nitrogen for 3- 4 times, adjust the reaction temperature of the system to 150 ° C and slowly pass 300 grams of propylene oxide, control the pressure ≤ 0.60 MPa, cool down to 90 ° C, remove the low boilers in vacuum, continue to adjust the reaction temperature of the system to 150 ° C and slowly pass Inject 500.0 grams of ethylene oxide, and control the pressure to ≤0.60MPa. After the reaction, neutralize and dehydrate after cooling to obtain C 16 h 33 O(CHCH 3 CH 2 O) 10 (CH 2 ...

Embodiment 3

[0057] The preparation of composition HF-3, preparation steps:

[0058] (1) Long-chain polyether nitrogen-containing compound (C 14 h 29 OCHCH 3 CH 2 O(CH 2 CH 2 O) 30 CH 2 CH 2 N(C 3 h 7 O) 2 C 5 h 10 SO 3 ) synthesis and preparation:

[0059] Add 107.0 grams of myristyl alcohol and 3.0 grams of potassium hydroxide to a pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, dehydrate under high vacuum for 1 hour, and then replace with nitrogen for 3- 4 times, adjust the reaction temperature of the system to 150°C and slowly pass in 60 grams of propylene oxide, control the pressure ≤ 0.60MPa, cool down to 90°C, remove the low boilers in vacuum, continue to adjust the reaction temperature of the system to 150°C and slowly pass through Inject 700.0 grams of ethylene oxide and control the pressure to ≤0.60MPa. After the reaction, neutralize and dehydrate after cooling to obtain C 14 h 29 OCHCH 3 CH 2 O(CH 2 CH 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com