Regulable dust-collecting, anti-static, and elastic sofa fabric and processing method thereof

A processing method and antistatic technology, applied in the field of fabric materials, can solve the problems of single structural components, poor wear resistance, poor functionality, etc., and achieve the effect of simple preparation process and good processing repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of cotton / CA / spandex fabric sofa fabric

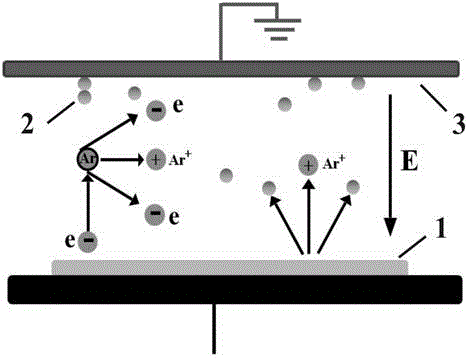

[0026] a. Weigh a certain weight of cotton fiber (3), and replace the target with Al target (1);

[0027] b. Fixing the obtained cotton fiber (3) on a physical vapor deposition device;

[0028] c. Under the action of electric field force, Al (1) forms neutral Al atoms (2) under the high-speed bombardment of Ar, and finally deposits on the cotton fiber (3). Control the thickness of the antistatic metal by sputtering time to adjust the antistatic effect;

[0029] D, the cotton fiber that is coated with Al particle and CA, spandex are blended by the ratio of 80:5:15, twisted into yarn;

[0030] e. Through the weaving process, it can be adjusted to absorb dust, anti-static, and elastic sofa fabric.

[0031] The specific steps of the weaving process include: winding: control the workshop temperature to 24°C, relative humidity to 64%, and control the winding speed of the 1332M winding machine to be a l...

Embodiment 2

[0032] The preparation of embodiment 2 polyester / CA / spandex fabric

[0033] a. Weigh a certain weight of polyester fiber (3), and replace the target with Al target (1);

[0034] b. Fix the obtained polyester fiber (3) on a physical vapor deposition device;

[0035] c. Under the action of electric field force, Al (1) forms neutral Al atoms (2) under the high-speed bombardment of Ar, and finally deposits on the polyester fiber (3). Control the thickness of the antistatic metal by sputtering time to adjust the antistatic effect;

[0036] d, the polyester fiber coated with Al particles is blended with CA and spandex in the ratio of 85:10:5, twisted into yarn;

[0037] e. Through the weaving process, it can be adjusted to absorb dust, anti-static, and elastic sofa fabric.

[0038] The specific steps of the weaving process include: winding: control the workshop temperature to 23°C, relative humidity to 60%, and control the winding speed of the 1332M winding machine to a linear sp...

Embodiment 3

[0039] Example 3 Preparation of modal fiber / / CA / spandex fabric

[0040] a. Weigh a certain weight of Modal fiber (3), and replace the target with Cu target (1);

[0041] b. Fix the obtained modal fiber (3) on a physical vapor deposition device;

[0042] c. Under the action of electric field force, Cu (1) forms neutral Cu atoms (2) under the high-speed bombardment of Ar, and finally deposits on the modal fiber (3). Control the thickness of the antistatic metal by sputtering time to adjust the antistatic effect;

[0043] d, modal fibers coated with Cu particles are blended with CA and spandex in a ratio of 60:25:15, twisted into yarn;

[0044] e. Through the weaving process, it can be adjusted to absorb dust, anti-static, and elastic sofa fabric.

[0045] The specific steps of the weaving process include: winding: control the workshop temperature to 25°C, relative humidity to 70%, and control the winding speed of the 1332M winding machine to a linear speed of 950 m / min to car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com