Integrated soaking radiator

A radiator and soaking plate technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc., can solve the problems of inability to guarantee the effect of flat heat pipes, high processing risks, and many solder joints, etc. Achieve the effect of lowering temperature, simple structure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

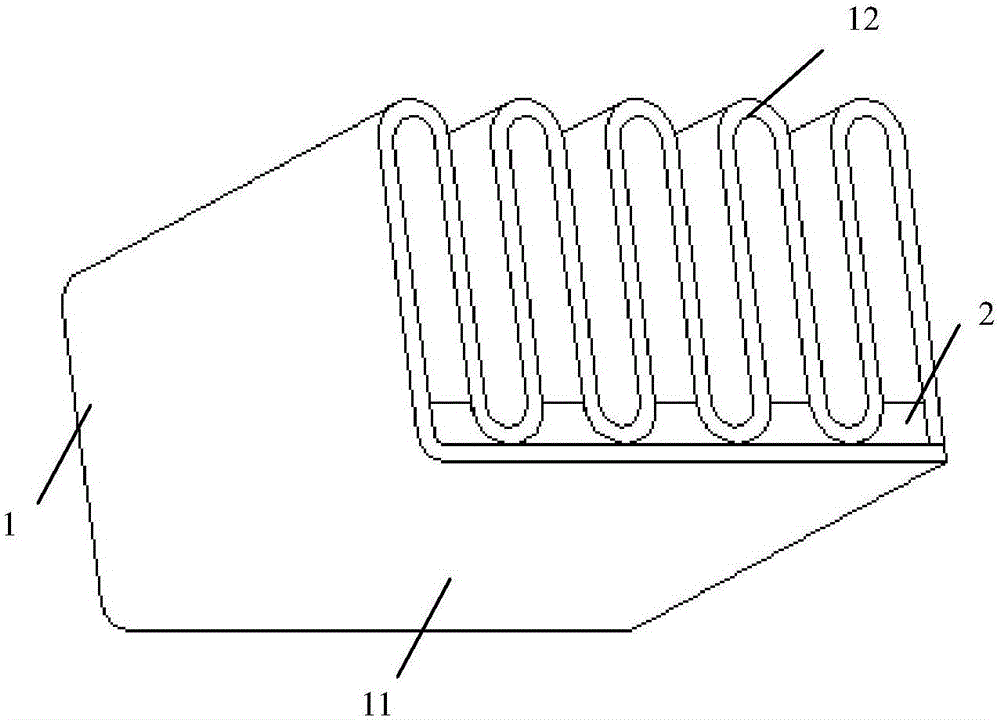

[0040] combine figure 1 , an integrated soaking radiator, which is formed by bending a soaking plate 1, one side of which is used as a bottom plate 11, and the other side is bent into a serpentine structure, serving as the main fin 12 of the radiator; the main fin 12 includes a flat plate and an arc-shaped plate connected at intervals, the flat plate is perpendicular to the bottom plate 11, and the arc-shaped plate at the bottom is welded to the bottom plate 11 through the connector 2;

[0041] The vapor chamber includes an upper cover plate and a lower cover plate. Channels 4 are respectively processed on the opposite sides of the upper cover plate and the lower cover plate. The channel structures of the upper cover plate and the lower cover plate are the same, and the channels are one or more Parallel serpentine channels, the connection surface of the upper cover plate and the lower cover plate are welded, and the channels opposite the upper cover plate and the lower cover p...

Embodiment 2

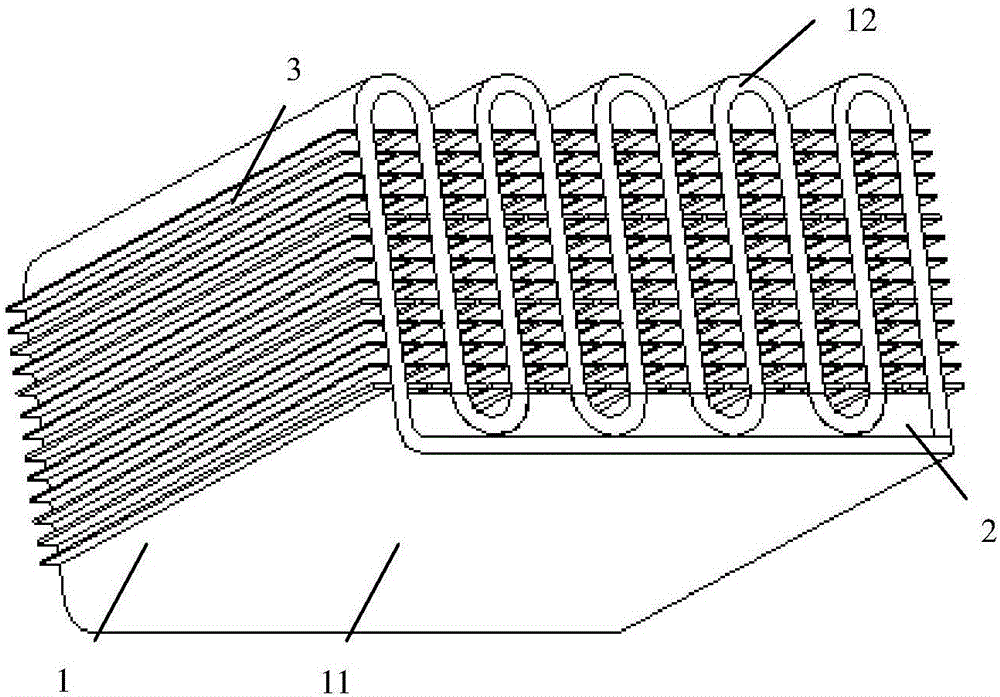

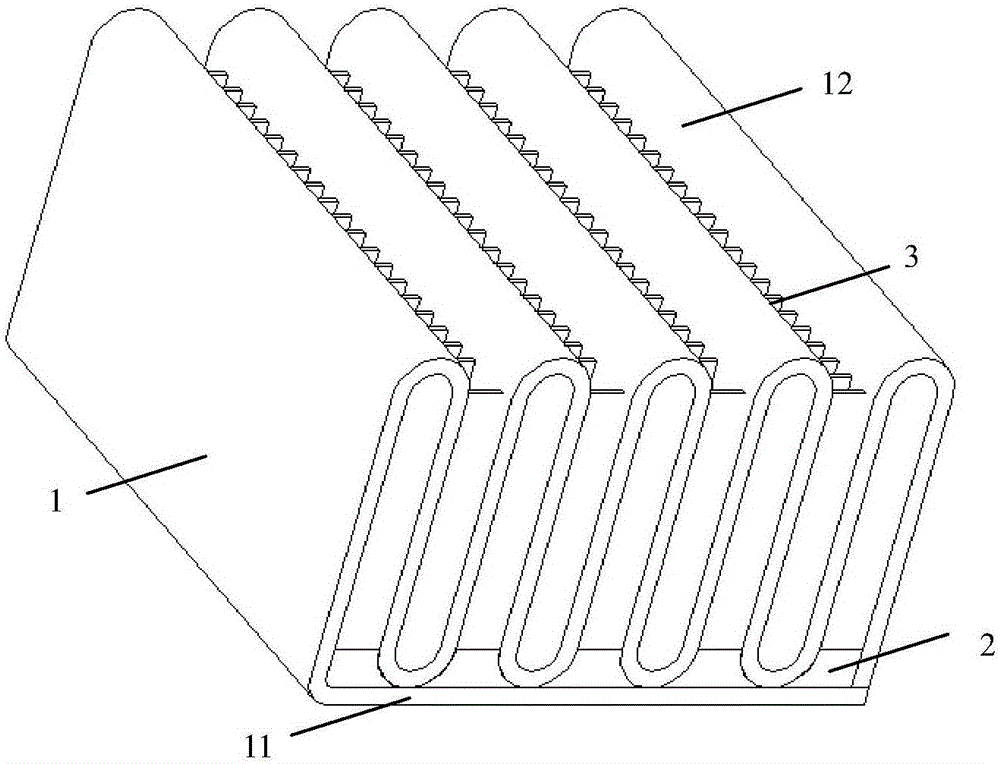

[0045] Such as figure 2 with image 3 As shown, the difference between this embodiment and Embodiment 1 is that several straight ribs 3 are welded on the surface of the main fin 12, and the straight ribs 3 are parallel to the bottom plate.

Embodiment 3

[0047] combine figure 1 , an integrated soaking radiator, which is formed by bending a soaking plate 1, one side of which is used as a bottom plate 11, and the other side is bent into a serpentine structure, serving as the main fin 12 of the radiator; the main fin 12 includes a flat plate and an arc-shaped plate connected at intervals, the flat plate is perpendicular to the bottom plate 11, and the arc-shaped plate at the bottom is welded to the bottom plate 11 through the connector 2;

[0048]The vapor chamber is a hollow structure. The inner wall of the cavity is provided with metal mesh or sintered metal powder to form a capillary structure. The internal cavity is evacuated and filled with working fluid. The working fluid is heated and evaporated in the cavity and refluxed and condensed through the capillary structure to realize heat transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com