Transient response high temperature sensor applied to complex environment

A high-temperature sensor and high-temperature-resistant technology, used in thermometers, instruments, and thermometers that use electrical/magnetic components that are directly sensitive to heat. Simple structure, low production cost, and the effect of enhancing sealing performance and positioning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

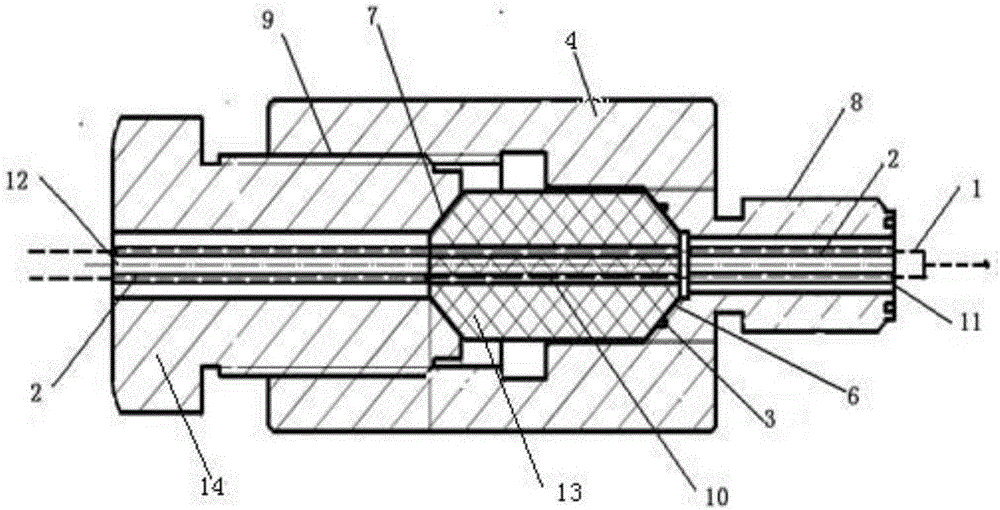

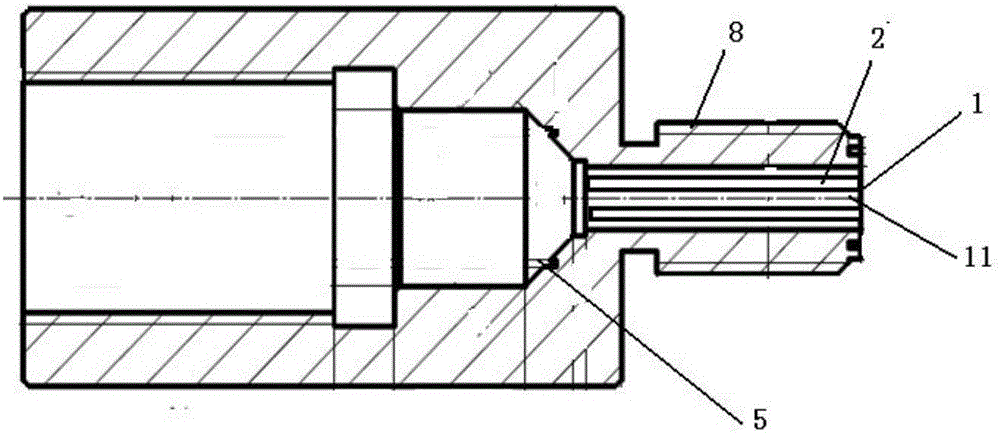

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] refer to Figure 1 to Figure 4 , the high temperature sensor of the present invention includes a thermocouple 1 , a tooling base 4 , a tooling pressure cap 14 and a sealing plug 13 .

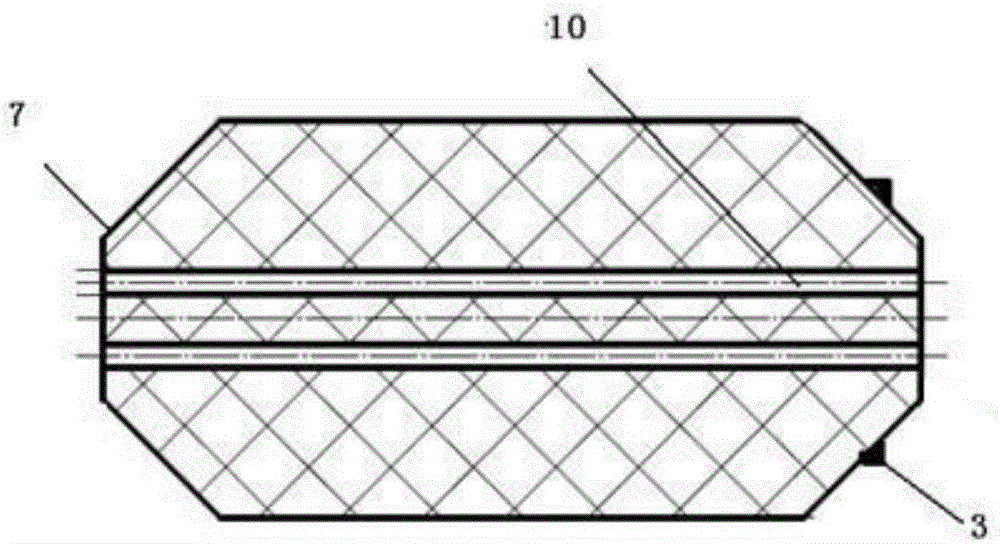

[0024] The sealing plug 13 is made of polytetrafluoroethylene material, and the two ends are tapered parts 7. At its bottom, that is, one side of the tapered part 7 is provided with a convex groove 3 matching the aforementioned groove, and the upper shaft of the sealing plug 13 A sealing plug aperture 10 with the same diameter as the thermocouple 1 is opened at the center position.

[0025] A mounting cavity and a connecting head 8 are provided on the tooling base 4, and a connecting thread is provided on the connecting head 8, and a high-temperature-resistant insulating cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com