Rub-impact sound emission fault position identification method based on near field sound source focusing positioning

A technology of fault location and identification method, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem that information is not fully utilized, the identification of rubbing fault sources fails to play its due role, Acoustic emission source location can not get satisfactory results and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

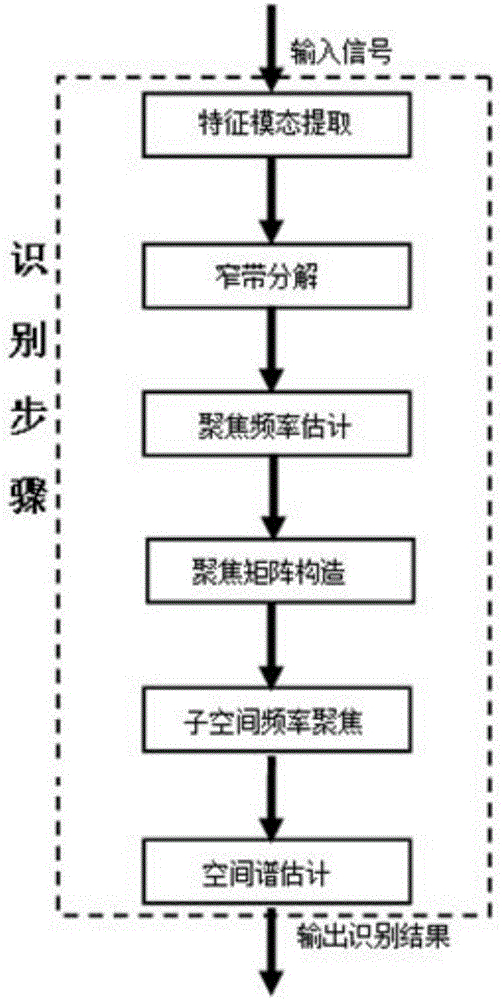

[0049] figure 1 It is a flow chart of multi-coherent acoustic emission source localization based on subspace focusing. The technical solution of the present invention will be further elaborated below in conjunction with the drawings and embodiments.

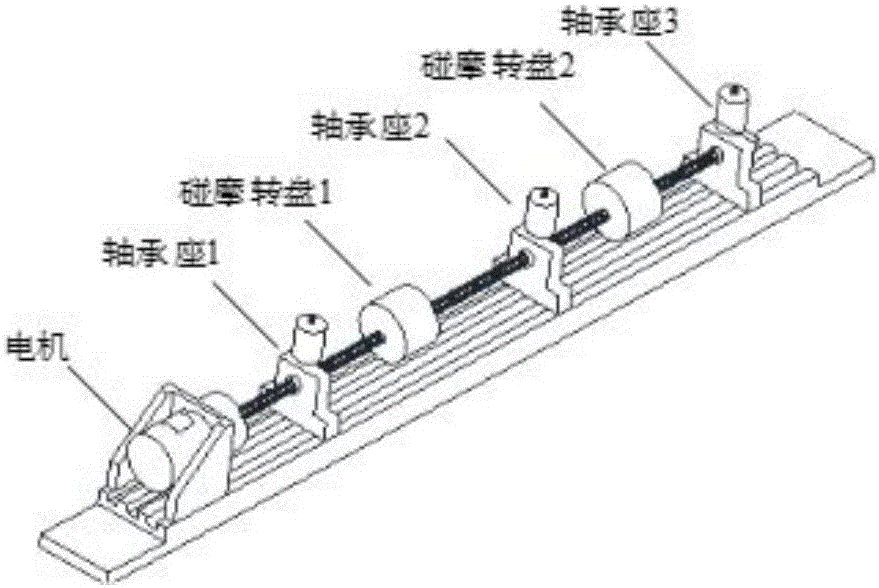

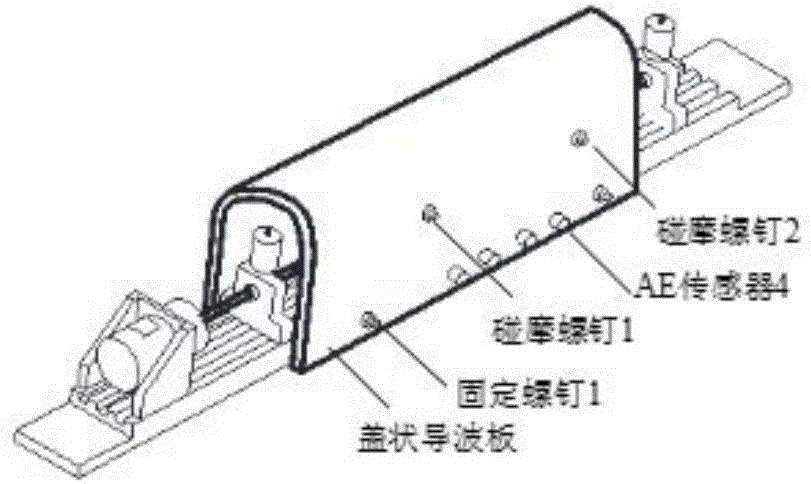

[0050] 1. Acquisition of rotor friction acoustic emission signal

[0051] The experimental system adopted in the present invention is shown in Fig. 2, which is composed of a rotor rubbing test bench, a cover-shaped waveguide, a governor, and an acoustic emission acquisition system. The rotor rubbing test bench is composed of three bearing housings with sliding bearings to support the rotor, two rubbing discs and rubbing screws. The rubbing screw can point to the center of the rotating shaft through the screw hole on the cover-shaped waveguide plate, and is in contact with the side of the disc. There are four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com